Method and device for continuously producing ultrathin stone polyurethane composite plates

A polyurethane and composite board technology, applied in the direction of lamination devices, chemical instruments and methods, layered products, etc., can solve the problem that ultra-thin stone polyurethane composite boards cannot be produced continuously, and achieve the solution of batch processing problems and product quality. Good, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

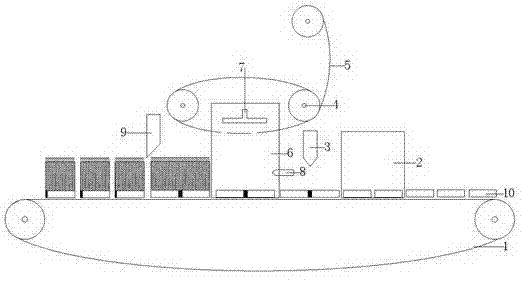

[0019] according to figure 1 As shown, it consists of transmission mechanism 1, dust removal box 2, seam filling machine 3, substrate conveying mechanism 4, substrate 5, constant temperature foaming box 6, substrate adjustment mechanism 7, polyurethane injection mechanism 8, finished product cutting mechanism 9, Composed of ultra-thin stone 10, etc., the transmission mechanism 1 is sequentially provided with a dust removal box 2, a constant temperature foam box 5 and a cutting mechanism 9; the transmission mechanism 1 includes a conveyor belt and a transmission wheel train; Dust removal mechanism: place the single ultra-thin stone 10 continuously on the transmission mechanism 1, leave a 5-10mm gap between each ultra-thin stone 10, and remove surface dust by wind when passing through the dust removal box 2; the seam filling machine 3 is set At the outlet of the dust removal box 2, the gap between the ultra-thin stone materials 10 is filled and closed and sent into the constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com