Method for preparing pentafluoroethane

A technology of pentafluoroethane and dichloroethane, which is applied in the field of preparation of pentafluoroethane, can solve problems such as difficult separation, reduced yield, and harmfulness, and achieve the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

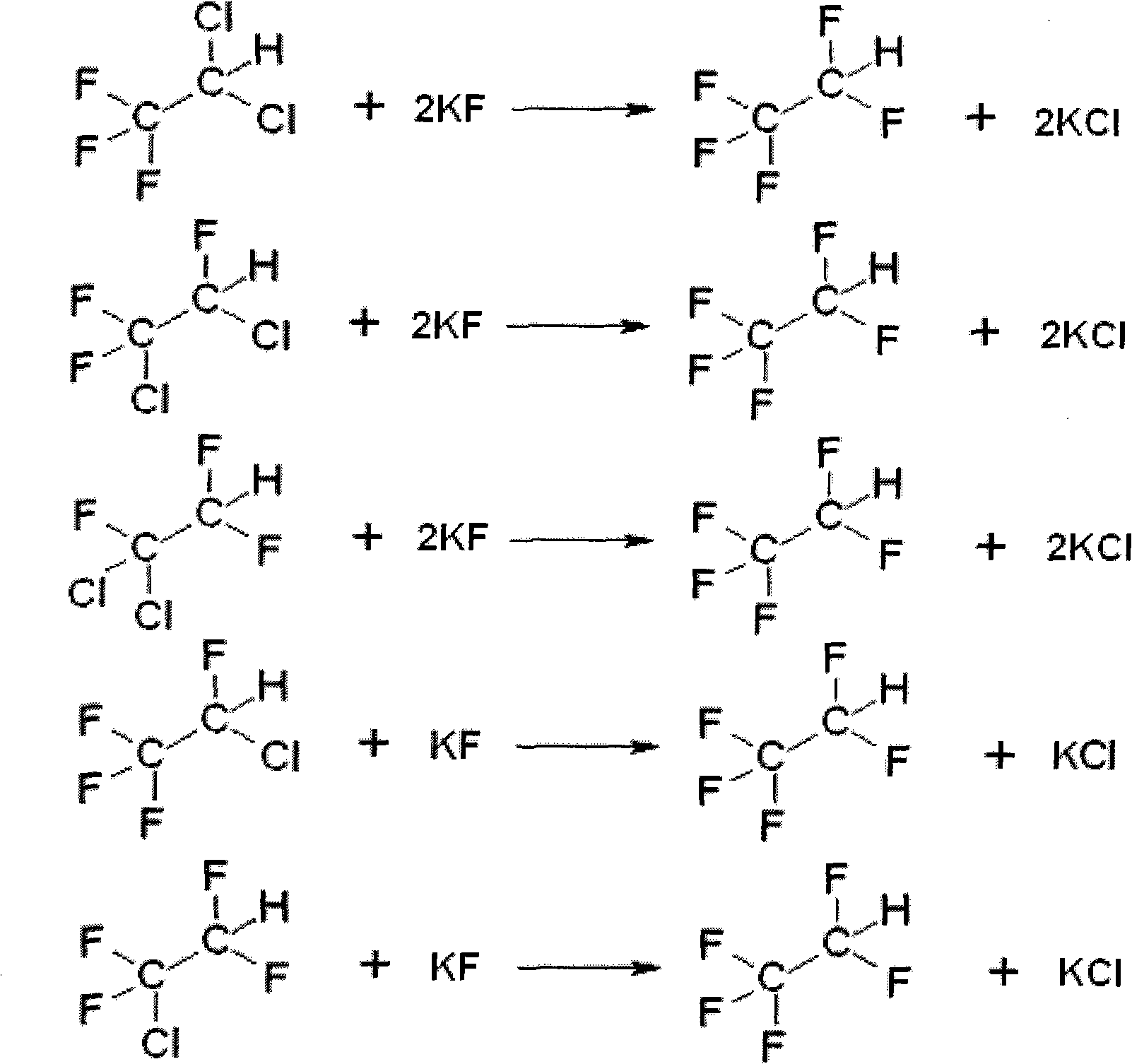

[0020] The invention discloses a preparation method of pentafluoroethane, using 1,1,1-trifluoro-2,2-dichloroethane or 1,1,1-trifluoro-2,2-dichloroethane The composition of its structural isomer reacts with potassium fluoride aqueous solution at a temperature of 280-330°C and a pressure of 12-13MPa to produce pentafluoroethane. The reaction equation is as follows:

[0021]

Embodiment 1

[0024] With a high-pressure metering pump, 27% potassium fluoride aqueous solution is driven into the coil type preheater with a speed of 1600Kg / h, and with another high-pressure metering pump, the mass percent content is 99.8% at a speed of 300Kg / h. The composition of 1,1,1-trifluoro-2,2-dichloroethane and its structural isomers is injected into another coil-type preheater, and the temperature of the preheater is between 180°C and 200°C.

[0025] After the potassium fluoride aqueous solution is preheated, it enters the coil superheater at a temperature of 310°C to 320°C. The overheated potassium fluoride aqueous solution and the preheated 1,1,1-trifluoro-2,2- The composition of dichloroethane and its structural isomers enters the bottom of a pipe reactor with a diameter of 27cm and a length of 26m for mixed reaction, the reaction temperature is 310°C-320°C, and the reaction pressure is 12MPa-13MPa.

[0026]After the potassium fluoride aqueous solution is mixed with the compos...

Embodiment 2

[0028] With a high-pressure metering pump, 28% potassium fluoride aqueous solution is driven into the coil type preheater with a speed of 830Kg / h; with another high-pressure metering pump, the mass percentage content is 99.8% The composition of 1,1,1-trifluoro-2,2-dichloroethane and its structural isomers is injected into another coil-type preheater, and the temperature of the preheater is between 180°C and 200°C.

[0029] After the potassium fluoride aqueous solution is preheated, it enters the coil superheater at a temperature of 320°C to 330°C. The overheated potassium fluoride aqueous solution and the preheated 1,1,1-trifluoro-2,2- The composition of dichloroethane and its structural isomer enters into the bottom of a pipeline reactor with a diameter of 27cm and a length of 26m for mixed reaction, the reaction temperature is 320°C-330°C, and the reaction pressure is 12MPa-13MPa.

[0030] After the potassium fluoride aqueous solution is mixed with the composition of 1,1,1-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com