Preparation method of aliphatic polycarbonate diol

A polycarbonate two, aliphatic technology, applied in the field of polycarbonate preparation, can solve the problems of separation difficulties, carbonate decarbonylation, low catalyst activity, etc., and achieve the effect of simple reaction operation and regular product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

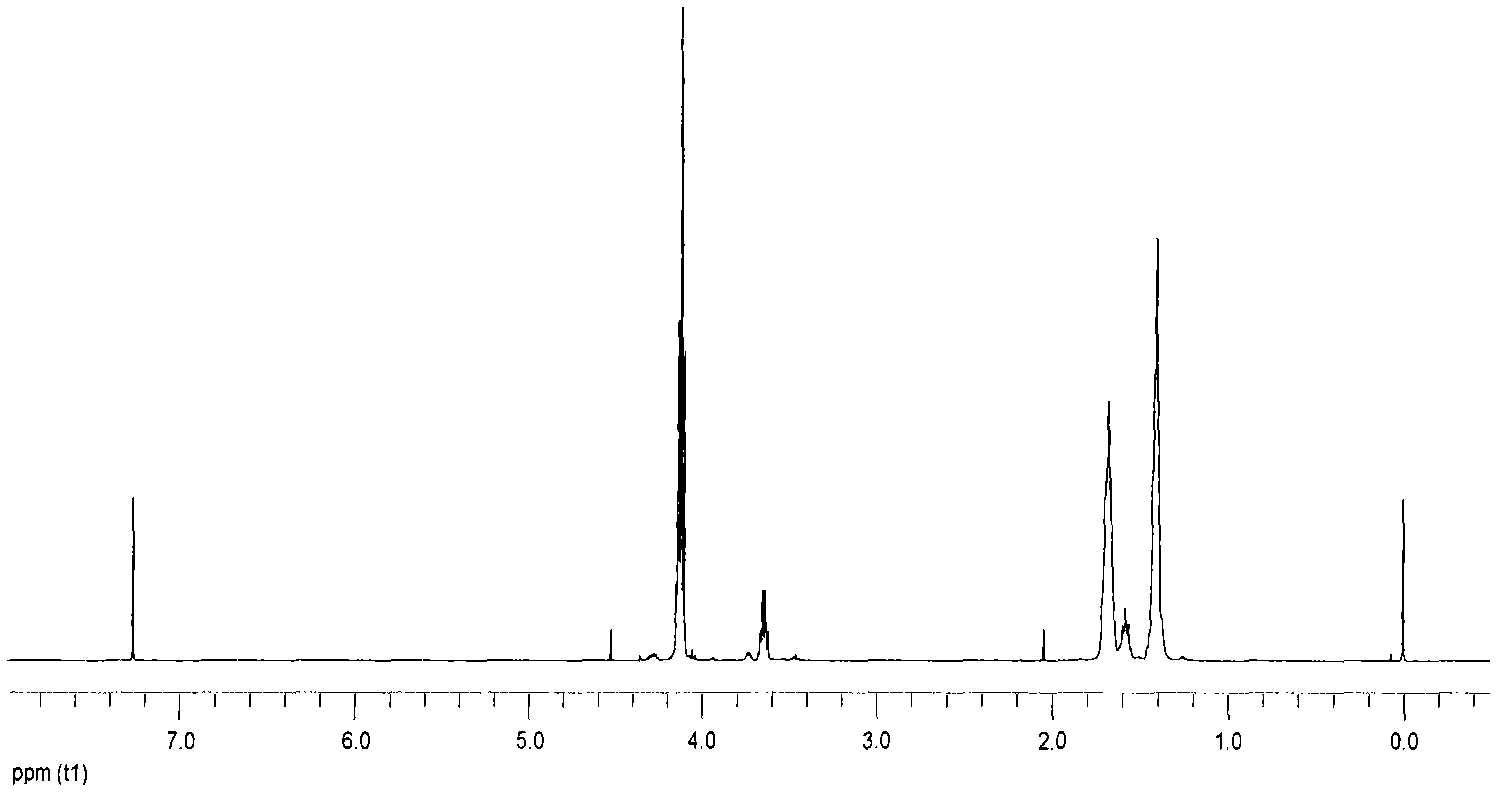

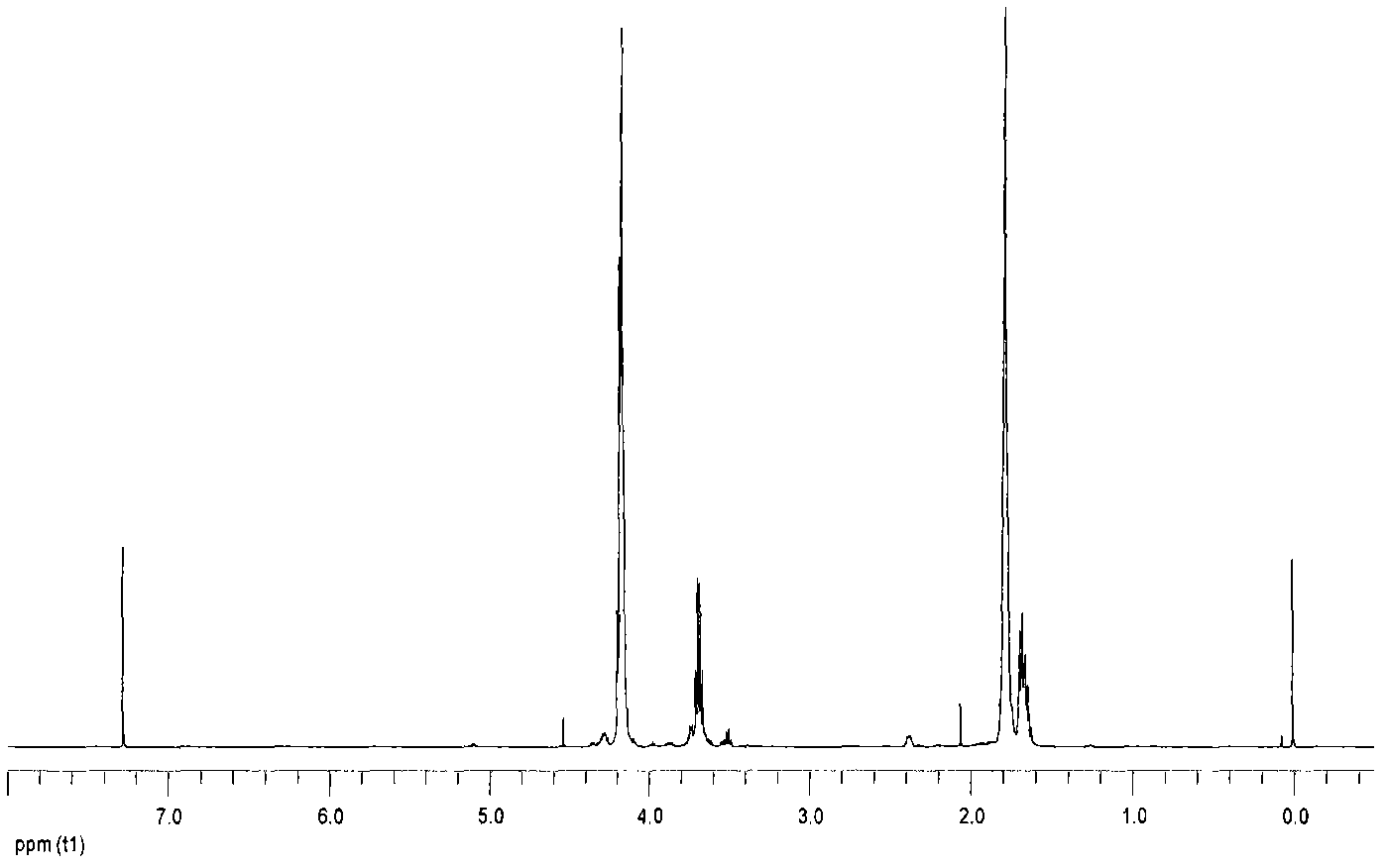

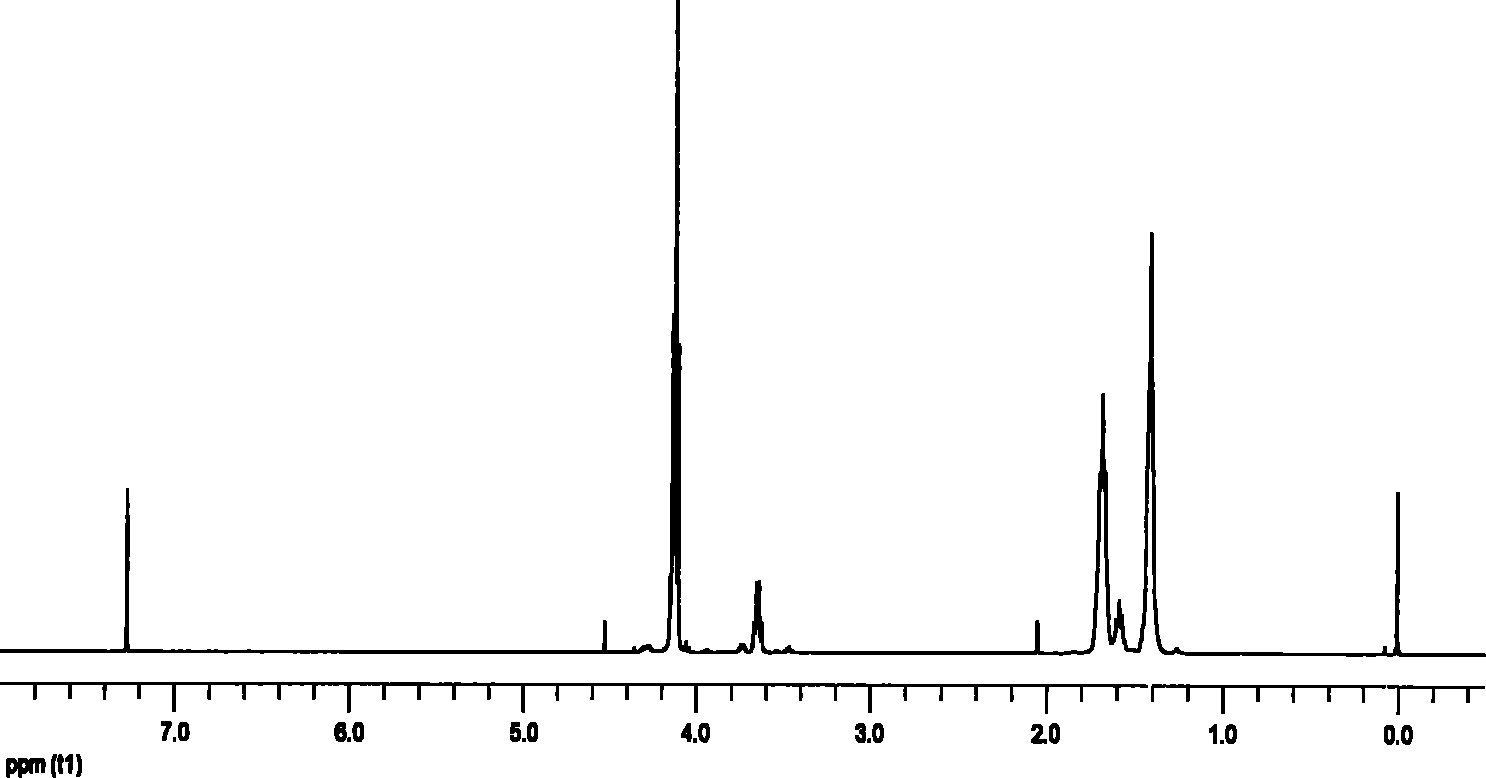

Image

Examples

Embodiment 1

[0018] In a 250mL glass flask, add 34.30g (0.39 mole) of ethylene carbonate, 35.40g (0.30 mole) of 1,6-hexanediol and 0.67g of zinc acetate, with 26g o-xylene as entrainer, in Reaction at 140°C for 8 hours, azeotropic separation of ethylene glycol, and then vacuum distillation at 1.33KPa at this temperature until no effluent was obtained to obtain 42.20 g of white waxy solid polycarbonate diol. The average molecular weight and the content of the decarboxylated ether segment were analyzed by nuclear magnetic resonance (the same below), and the analysis results are shown in Table 1.

Embodiment 2

[0020] In a 150mL glass flask, add 13.20g (0.15 mole) of ethylene carbonate, 35.40g (0.30 mole) of 1,6-hexanediol and 0.50g of zinc acetate, with 26g p-xylene as entrainer, in React at 140°C for 4 hours, react at 1607°C for 4 hours, azeotropically separate ethylene glycol, then distill under reduced pressure at 1.99KPa at this temperature until there is no effluent, and obtain white waxy solid polycarbonate Dihydric alcohol 36.30g, analysis result is shown in Table 1.

Embodiment 3

[0022] In a 150mL glass flask, add 66.00g (0.75 mole) of ethylene carbonate, 17.70g (0.15 mole) of 1,6-hexanediol and 0.20g of zinc acetate, with 26g m-xylene as an entrainer, in Reaction at 147°C for 8 hours, azeotropic separation of ethylene glycol, and then vacuum distillation at 1.60KPa at this temperature until no effluent was obtained to obtain 37.00 g of white waxy solid. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com