Steam turbine condenser exhaust pipe

A technology of condenser and steam turbine, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of limited number of exhaust pipes and small volume ratio of exhaust pipes, and achieve small flow resistance, uniform heat load, The effect of improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

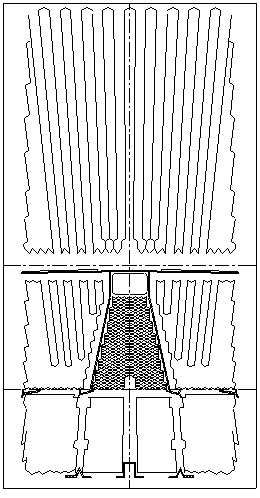

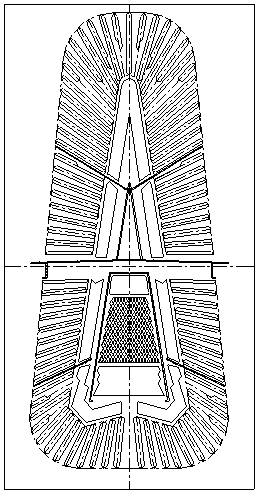

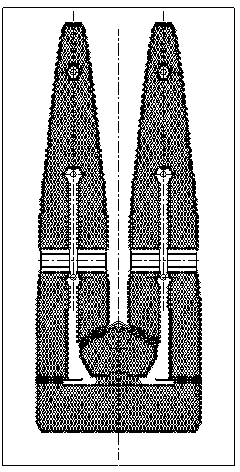

[0021] Such as Figure 4 As shown, the present invention is a row pipe of a steam turbine condenser. The row pipes are a plurality of cooling pipes 19 with uniform spacing and parallel axes. The cooling pipes 19 constitute two independent pipe-containing areas, the air cooling zone 14 and the main condensation zone. The main condensation zone is arranged around the air cooling zone 14.

[0022] Condenser exhaust pipe of the present invention, has designed a kind of new arrangement mode of condenser cooling tube bundle: the outline shape of the projection of the envelope line of its tube-containing area on the plane perpendicular to the axis of cooling tube 19 is torch-like , that is, the cross-sectional profile of the tube-containing area perpendicular to the axis of the cooling tube 19 is a symmetrical torch shape, and the projection plane (section) is parallel to the condenser end tube plate 21. The air cooling zone 14 is arranged at the middle and lower part of the "torch"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com