Solid oxide fuel cell stack

A fuel cell stack and solid oxide technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of increasing the manufacturing cost of the battery stack, short circuit of the battery stack, multi-cell stack, etc., and achieve improved stability and output performance, small internal gas pressure difference, and solve the effect of cross-gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

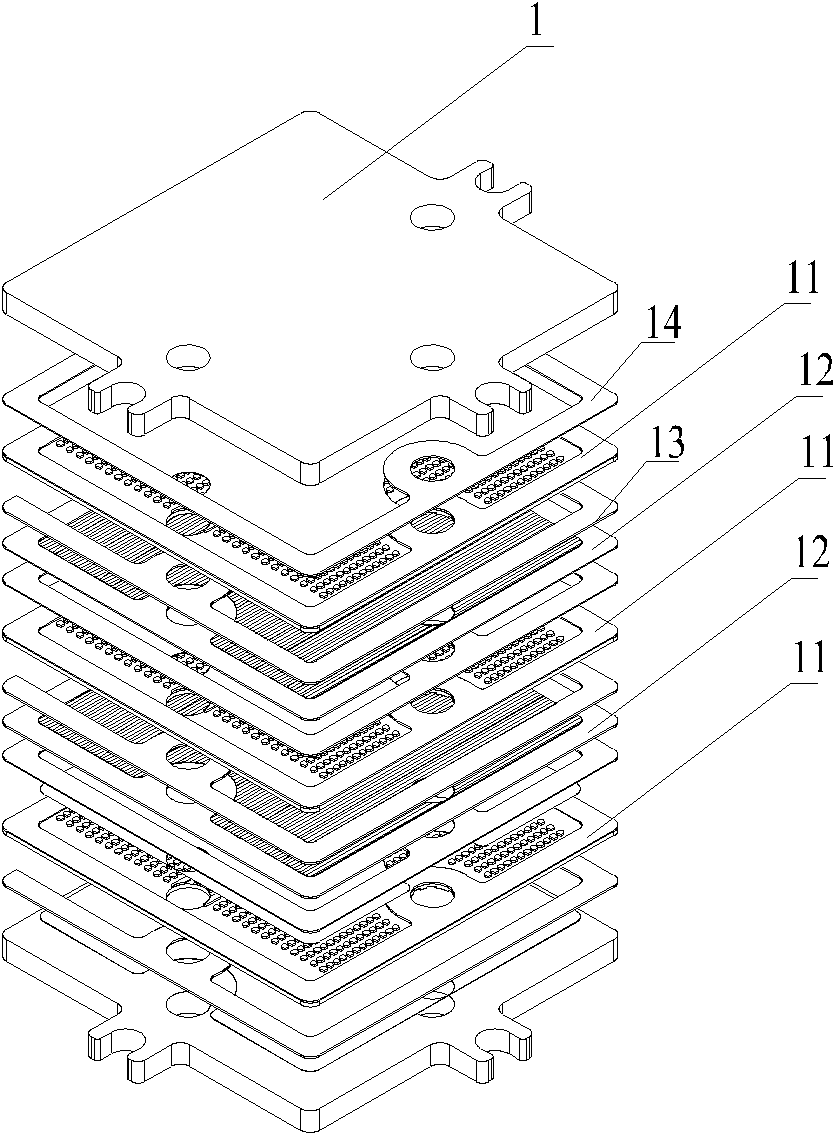

[0064] Prepare the following components for backup:

[0065] Single cell: Prepare an anode-supporting single cell sheet with a specification of 10cm×10cm, the anode is , and the cathode is , and an oxidizing gas inlet hole is processed on one edge of the single cell by laser cutting, and the oxidizing gas is connected with the oxidizing gas A fuel gas inlet hole and a fuel gas outlet hole are processed on two vertical edge portions of the edge portion where the air inlet hole is located;

[0066] Connector: The material is SUS430, the thickness is 2.5mm, and the dot matrix arrangement (dot matrix arrangement) round bumps are etched on the anode side and the cathode side of the connector, and the height of the round bumps on both sides is 0.5mm ;according to Figure 4 and Figure 6 As shown, an anode-side sealing edge and a cathode-side sealing edge each having a width of 3.5 mm are machined, wherein the cathode-side sealing edge has an opening.

Embodiment 2

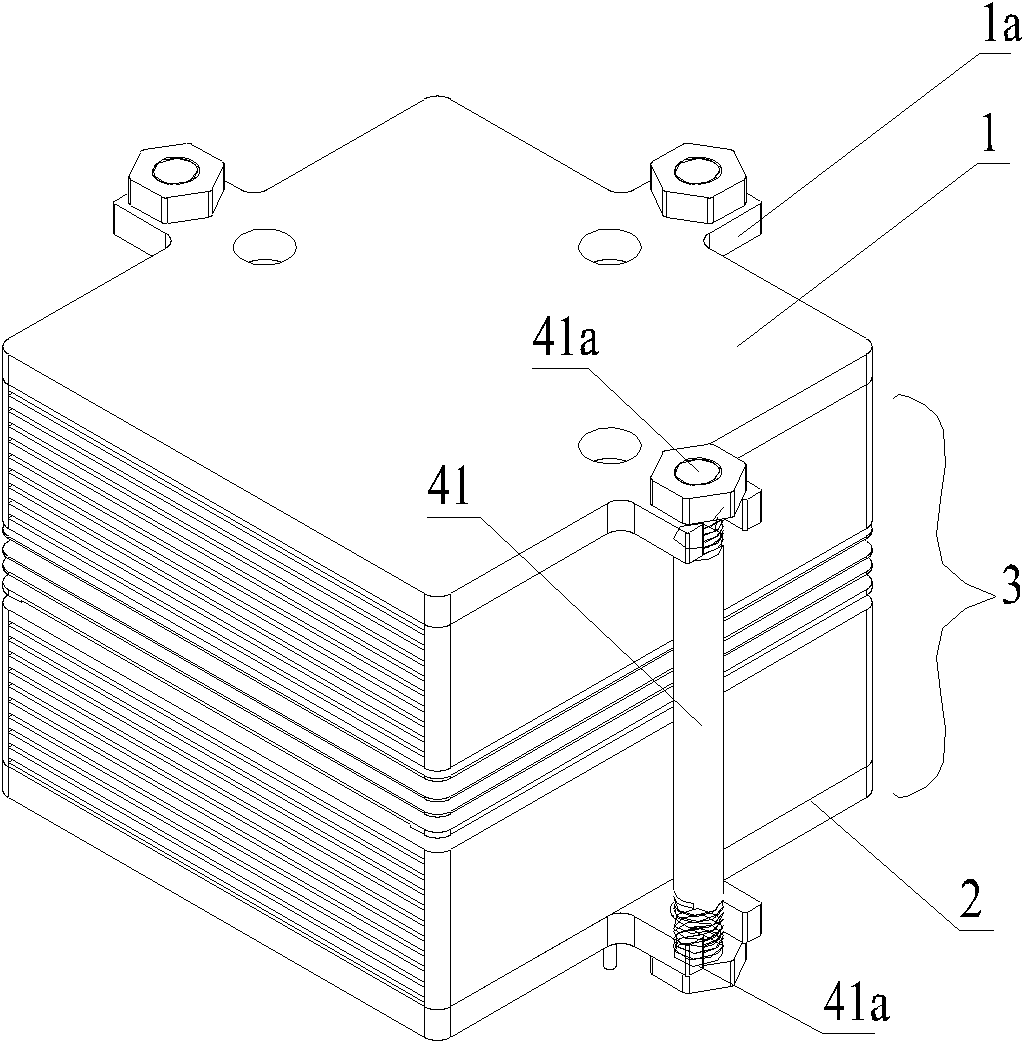

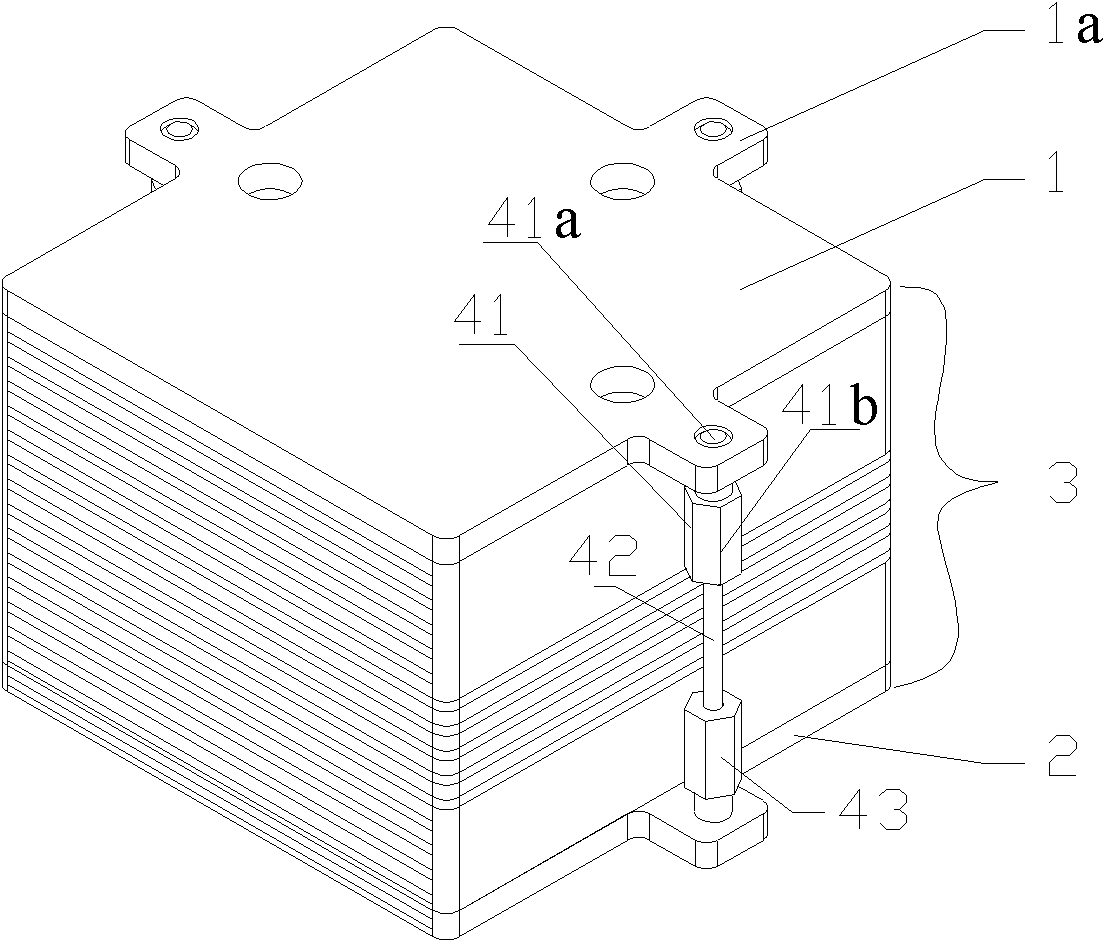

[0074] Take the upper collector plate, lower collector plate and 5 pieces of connectors, 5 pieces of oxidizing gas seals, 5 pieces of fuel gas seals, 4 pieces of single cells, and 4 pieces of nickel foam according to the upper collector plate / fuel gas seal / (connector / oxidizing gas seal (nickel foam) / single cell)×4 / connector / oxidizing gas seal / lower collector plate to assemble into a 4-unit cell stack assembly, and then take the bolt assembly to fix the upper collector Flow plate and lower collecting plate.

[0075] The assembled battery stack assembly was heated from room temperature to 850°C over 12 hours, held for 4 hours and then pressurized at 0-200kg to test performance under different conditions. The obtained I-V curves are as follows: Figure 11 shown.

[0076] Figure 11 Middle: when the battery stack prepared in this example is heated at 850°C, 200kg pressure and H 2 :Air=8:19sccm cm -2 Under the same conditions, after 2 hours of reduction, the measured maximum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com