Method of producing anti-glare film

An anti-glare film and technology of preparation steps, applied in the directions of coating, instrument, transportation and packaging, can solve the problem of difficult viewing of the display due to reflected light, and achieve the effect of preventing whitening phenomenon and preventing the reduction of productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

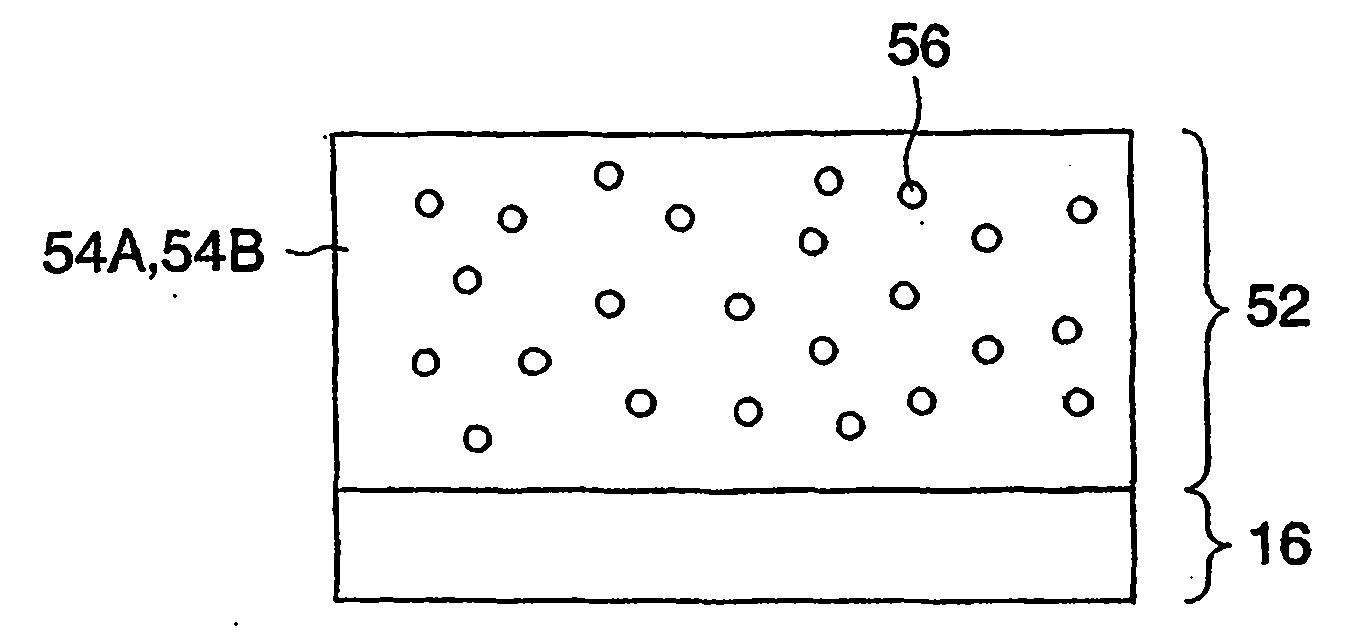

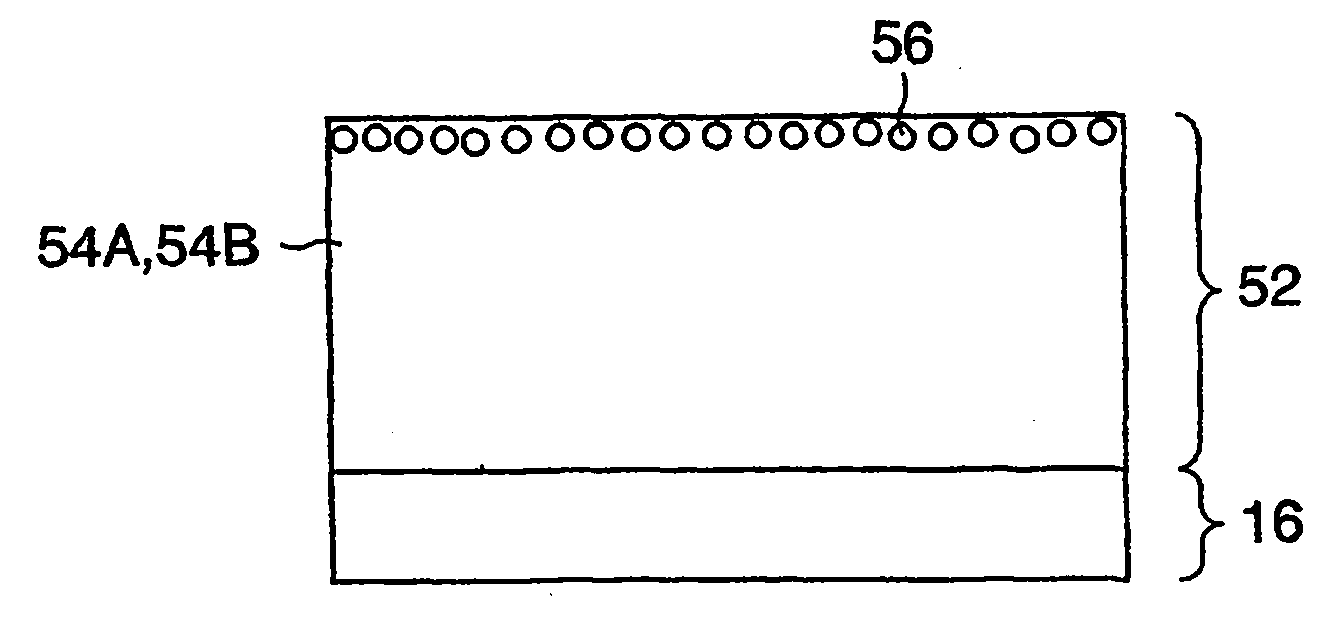

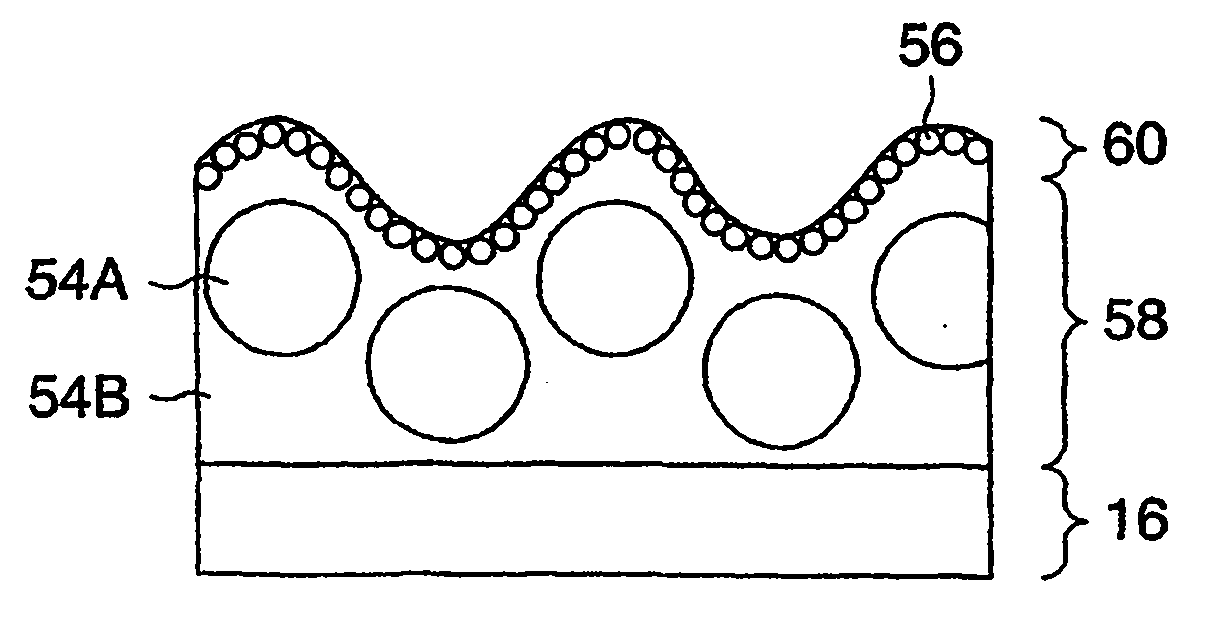

[0047] Figures 1A to 1C is an explanatory diagram illustrating an example of a method of producing an antiglare film and figure 2 is a schematic diagram showing one example of an apparatus for producing an antiglare film. Although the present embodiment will be described with an example in which a coating solution containing two kinds of resins A and B is used, the basic concept is the same when two or more kinds of resins are contained.

[0048] (Step of mixing coating solution)

[0049] First, in the method for producing an antiglare film according to the present invention, two mutually incompatible resins A and B are dissolved in a solvent, and particles are further contained therein to prepare a coating solution (coating solution preparation step ).

[0050] As the particle and resin material, those described later can be used. Also, as the mixing method, any method may be employed without any limitation as long as the resin material is dissolved in the solvent and th...

Embodiment 1

[0130] On triacetyl cellulose (Fujitac, produced by Fujifilm Corporation) serving as a support with a thickness of 80 μm, the following coating solution was coated so that the thickness of the dry film became 6 μm. After coating, the coated film was dried at 60° C. for 1 minute at a drying air velocity of 0.5 m / sec, followed by heat treatment at 100° C. for 1 minute. In this way, an antiglare film provided with an antiglare layer was produced.

[0131]

[0132] The surface of hollow silica particles having an average particle diameter of 20 nm was hydrophobized with 3,3,3-trifluoropropylmethyldichlorosilane. A coating solution was prepared by dissolving 2 parts by mass of cellulose propionate, 15 parts by mass of an acrylic resin, and 0.2 parts by mass of hydrophobized hollow silica particles in 80 parts by mass of methyl ethyl ketone. The critical solid content concentration of this system is 29%.

[0133] The antiglare film thus obtained was cut into a predetermined size...

Embodiment 2

[0142] An antiglare film was prepared in the same manner as in Example 1 except that the particles used had an average particle diameter of 40 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com