Method for purifying degraded amine solution

A technology for deteriorating amine and amine liquid, which is applied in the field of filtration and removal of impurities and amine liquid purification of strong base-weak base mixed resin to achieve the effect of improving utilization rate, improving removal effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

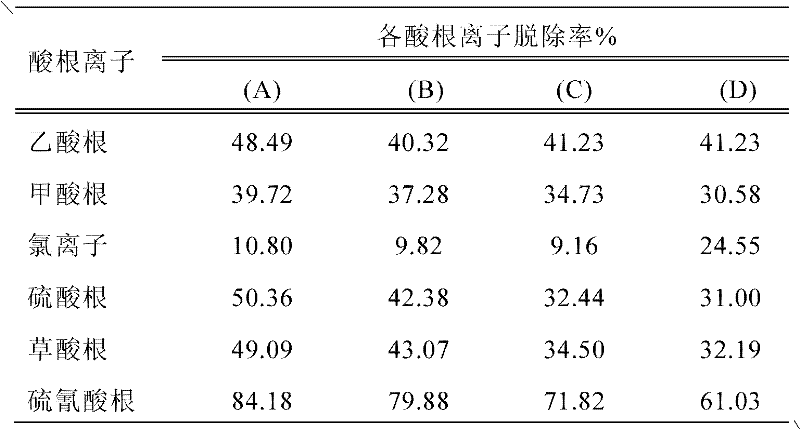

[0027] In four 100mL beakers, put 10mL of fresh strong basic resin A (D201), strong basic resin B (201), weak basic resin C (D301) and weak basic resin D ( D318), add 25mL of degraded amine solution and soak for 4h. The removal effect of each ion exchange resin on each ion is shown in Table 1. It can be seen from Table 1 that the removal effect of each type of resin on each acid ion is not the same, and the removal effect is related to the basic strength and pore structure of the resin, and the selectivity of each resin to different acid ions is different. .

[0028] Table 1 The removal effect of four different resins on each acid radical ion

[0029]

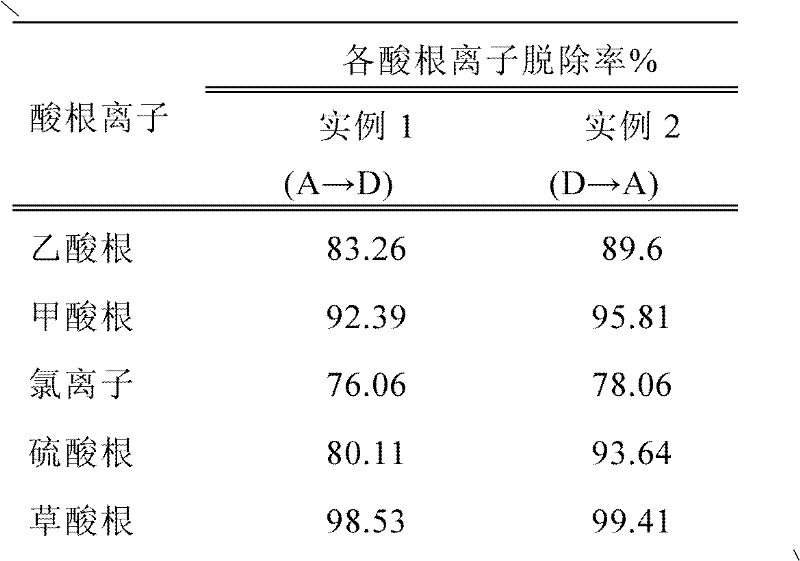

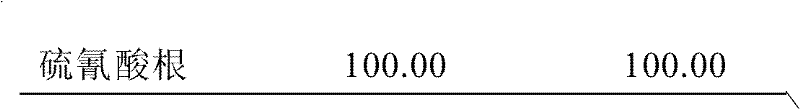

[0030] The fixed bed is filled with molecular sieve as the filter medium to filter the solid impurities of the degraded amine liquid. Add 6mL of mixed resin into a glass column with an inner diameter of 10mm, resin A and resin D each 3mL, the filling height-to-diameter ratio of the mixed resin is 3:1, where the resin A and resin D...

Embodiment 3~6

[0038] Fill the 6mL resin A in Example 1 into a glass column with an inner diameter of 10mm, and carry out the investigation experiment of the amount of regenerant in turn. 5mL and 15mL of 8wt% lye are added respectively. After the lye is completely removed from the glass column, add Rinse with deionized water until the pH of the solution is close to neutral, add 10 mL of the filtered amine solution, and test the ion content in the amine solution after running twice. The detection and analysis results are shown in Example 3 and Table 4 Example 4 shown.

[0039] Examples 5 and 6 respectively investigated the influence of the concentration of the regeneration solution on the removal effect of each acid radical, adding 10 mL of 2wt% and 6wt% lye respectively, after the lye was removed from the glass column, added deionized water to wash, the pH value of the solution When it is close to neutral, add 10 mL of the filtered amine solution, and detect the ion content in the amine solutio...

Embodiment 7

[0043] The fixed bed is filled with activated carbon as a filter medium to filter the solid impurities of the degraded amine liquid. Add 6 mL of mixed resin into a glass column with an inner diameter of 10 mm, resin A and resin D 3 mL each, and mix the two resins. The filling height-to-diameter ratio of the mixed resin is 1:1. Add 10mL of the filtered amine solution, and keep the space velocity at 50h at 10℃ -1 , After running twice, the content of each ion in the amine solution was detected. The results showed that the mixed resin can have a good removal effect on each ion in the amine solution.

[0044] Regenerate the resin after the exchange experiment and remove it. Add 10 mL of 6wt% lye to the resin after the exchange experiment. After the lye is completely removed from the glass column, add deionized water for high-pressure water injection countercurrent flushing. At 30℃, the space velocity is 40h -1 , Until the pH value of the solution is close to neutral, add 10 mL of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com