Flexible production process of door cover

A flexible production and process technology, applied in the field of flexible production process of door covers, can solve the problems of low equipment utilization rate, large number of personnel, large floor area, etc., to reduce investment costs, reduce the number of personnel, and improve equipment utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically described below in conjunction with the accompanying drawings.

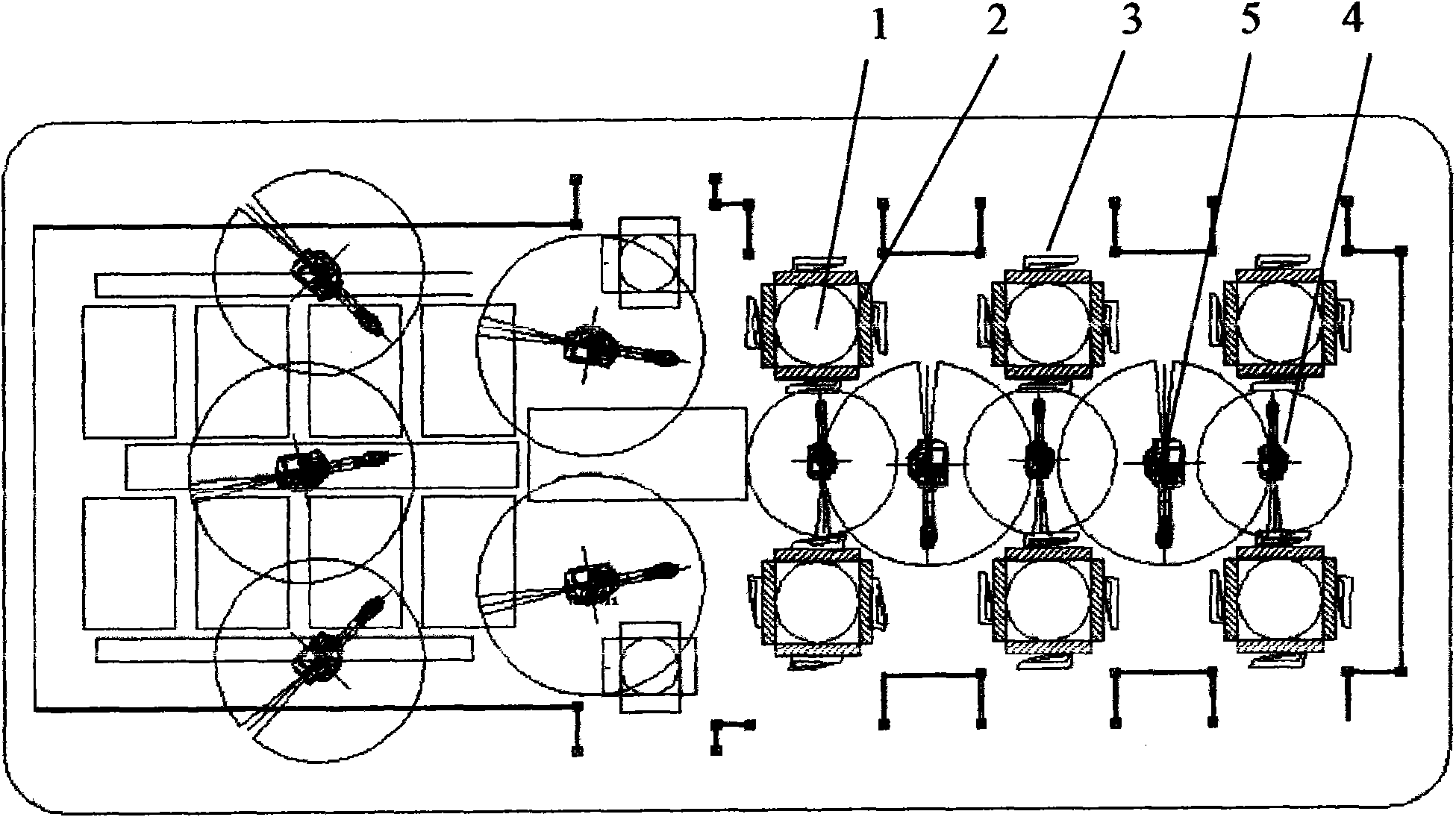

[0024] Such as figure 1 As shown, eight kinds of door cover welding jigs 2 (four types on one side) can be installed on the left and right sides of the rotating table 1, and eight kinds of door covers can be produced in mixed lines. When the main line produces model A (main line beat 200S), robot 4 welds the door + cover 3 of model A on the left and assembles the right door cover parts in the first 100S; in the last 100S, welds the right door cover parts and at the same time Assemble the left door cover parts; the transportation between the workpieces is completed by the handling robot 5. Through the above measures, the flexible production of multi-model door covers can be satisfied, while reducing investment, personnel, and space.

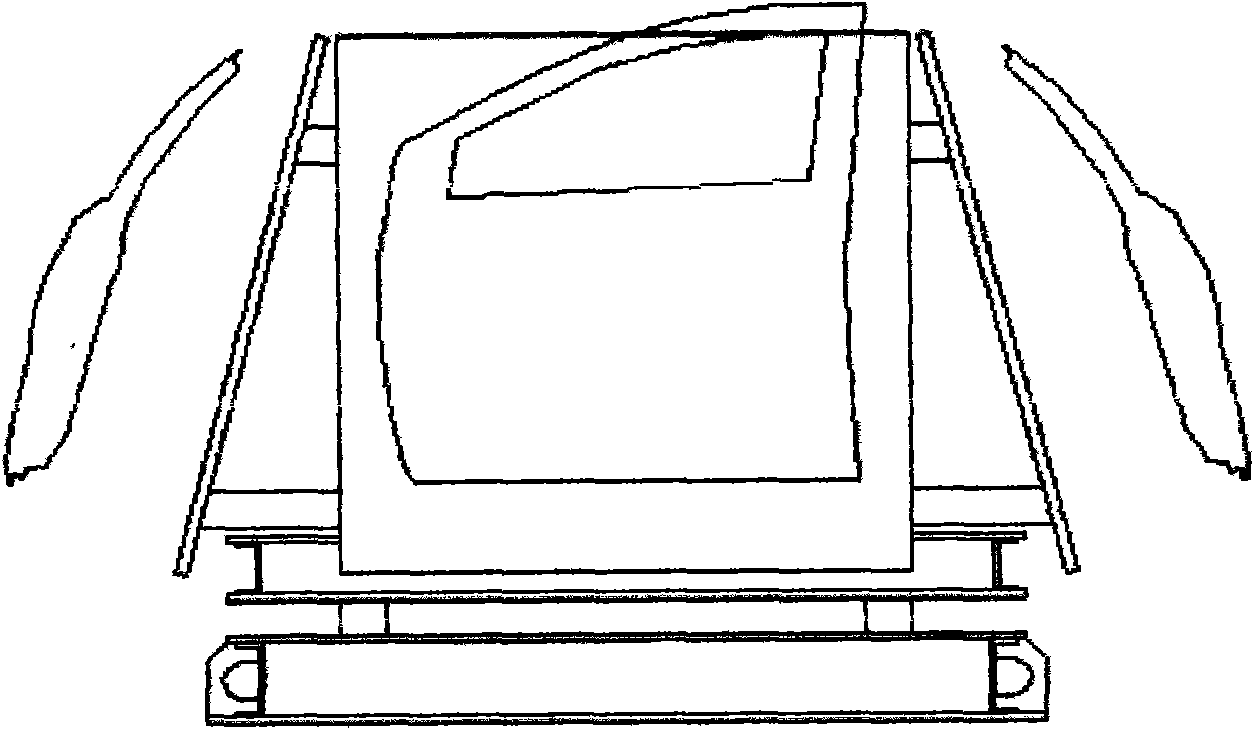

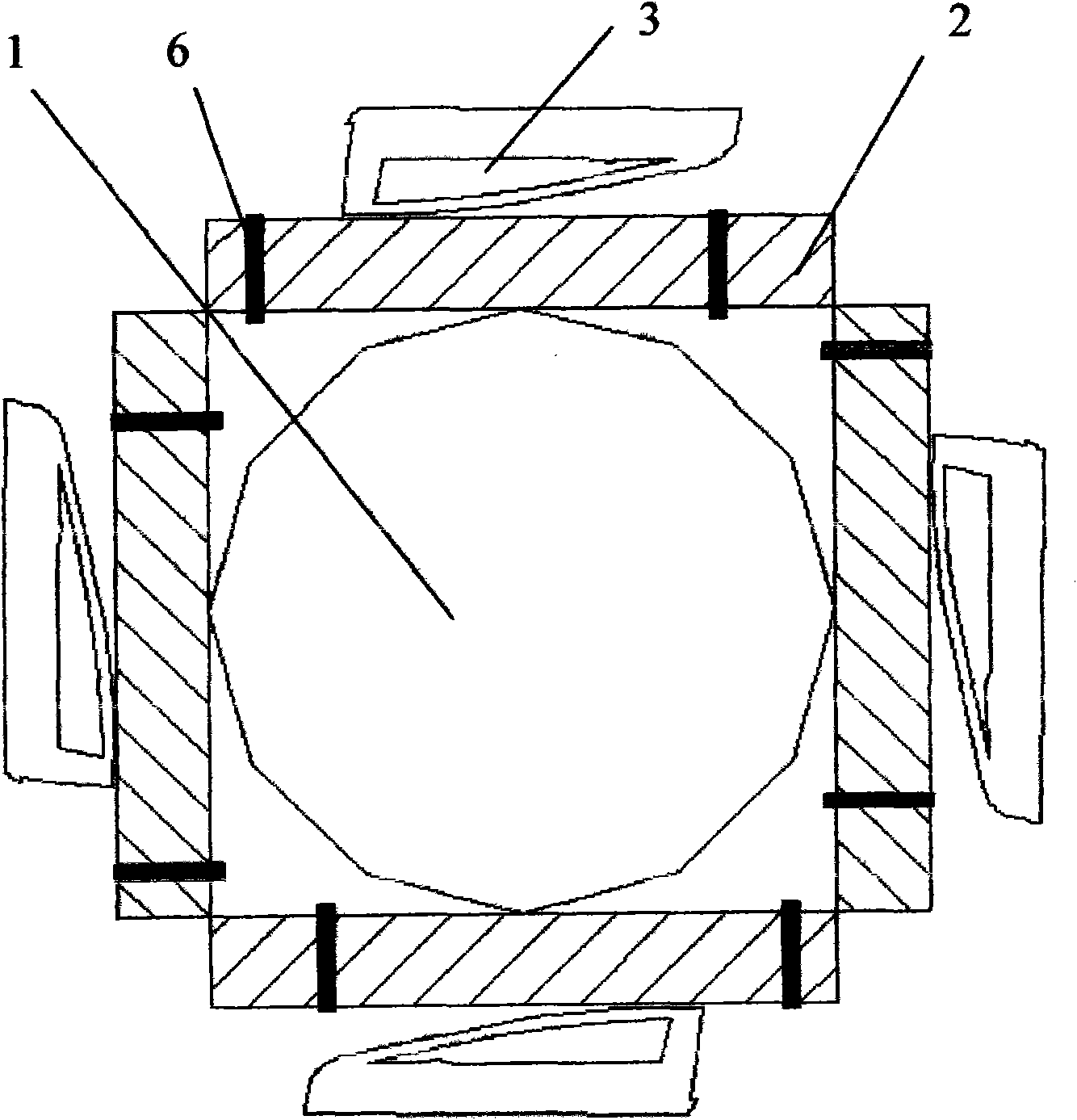

[0025] The rotary table adopts the standard TUNKERS rotary table, such as figure 2 , 3 As shown, assemble the welding jig 2 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com