Fabric with function of bidirectional adjustment of heat humidity

A two-way adjustment, fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of increased sweating intensity, poor heat and humidity adjustment ability, and reduced perspiration performance of fabrics, and achieve heat and moisture transfer capacity Improvement, heat transfer ability improvement, high moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

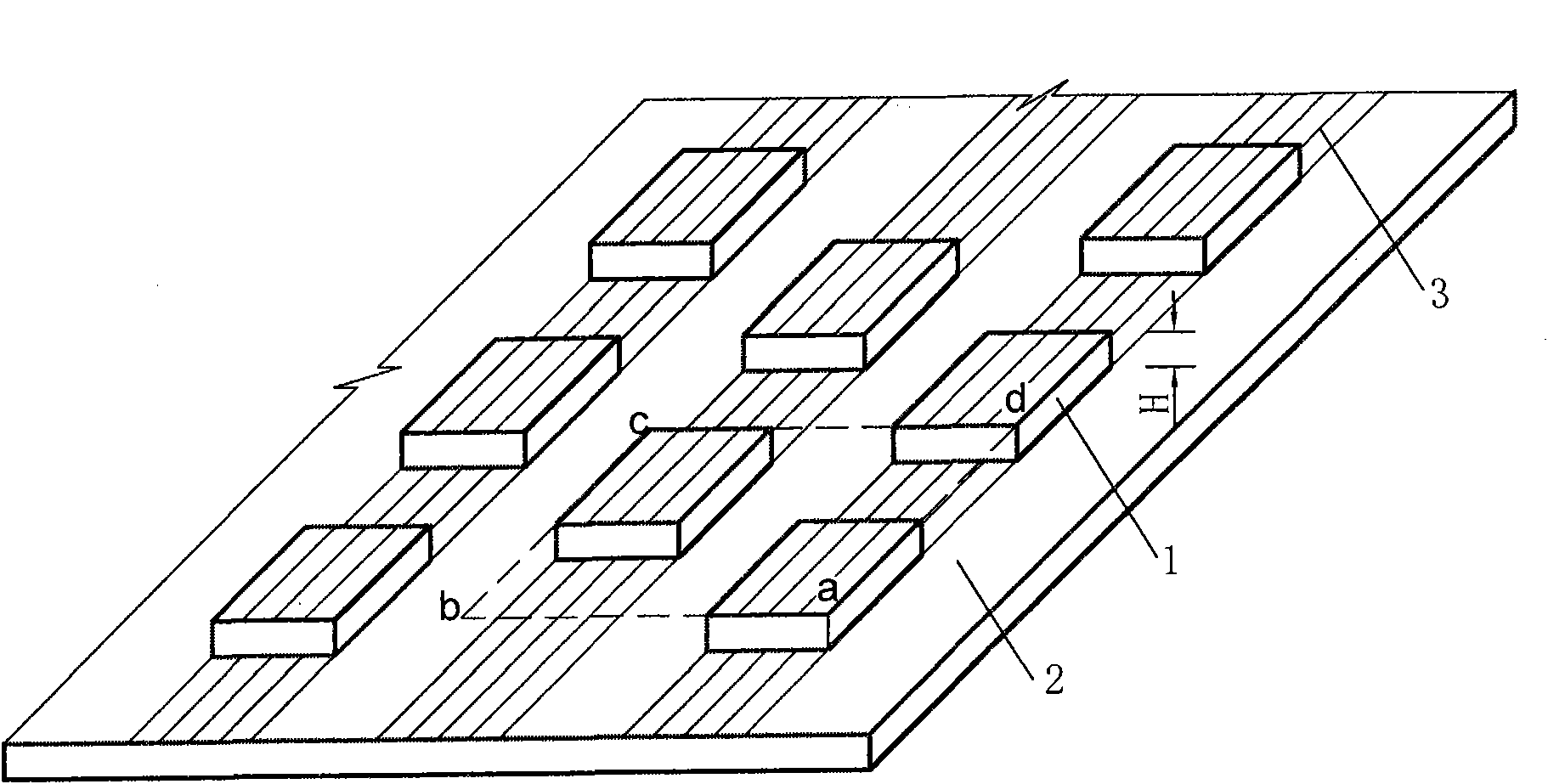

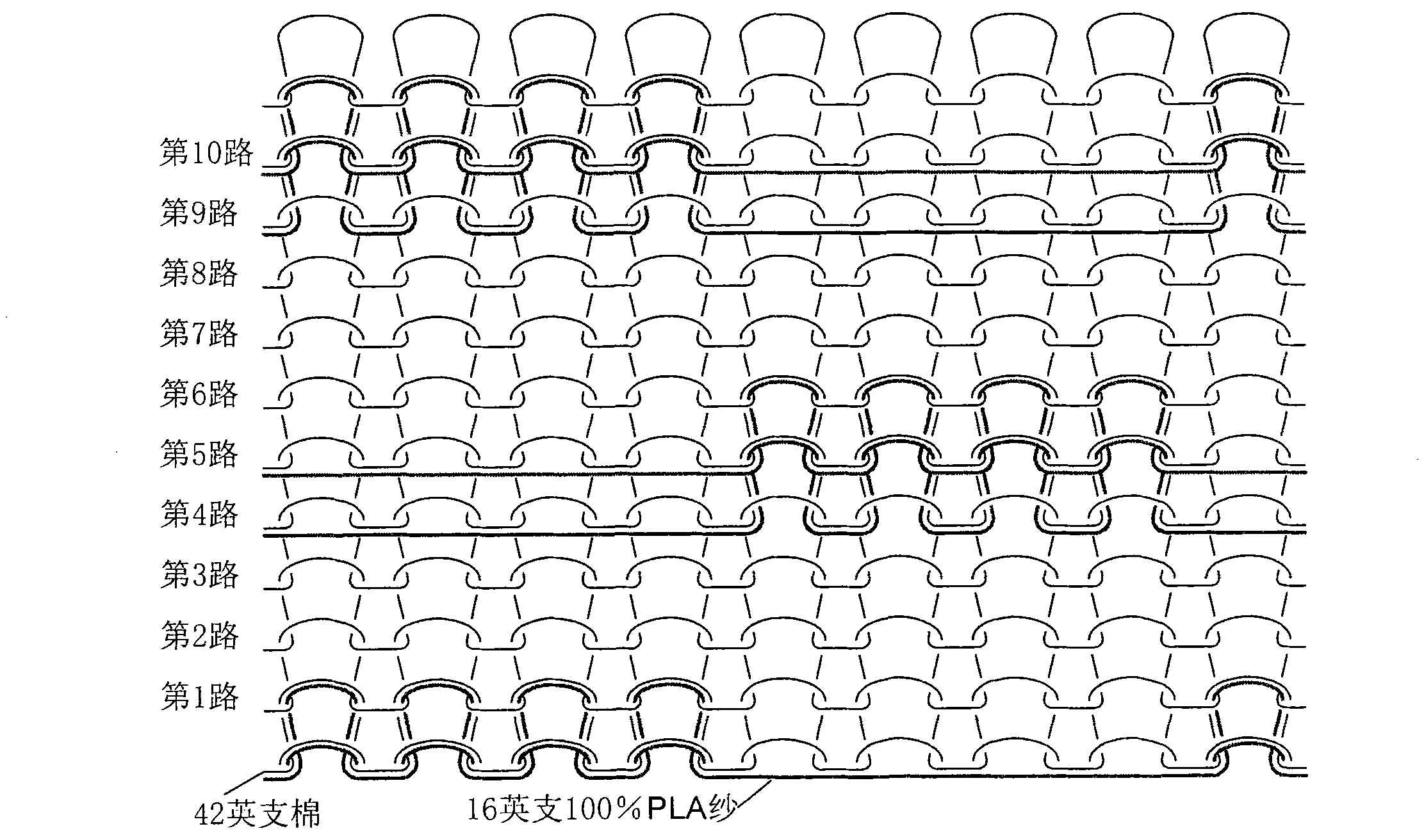

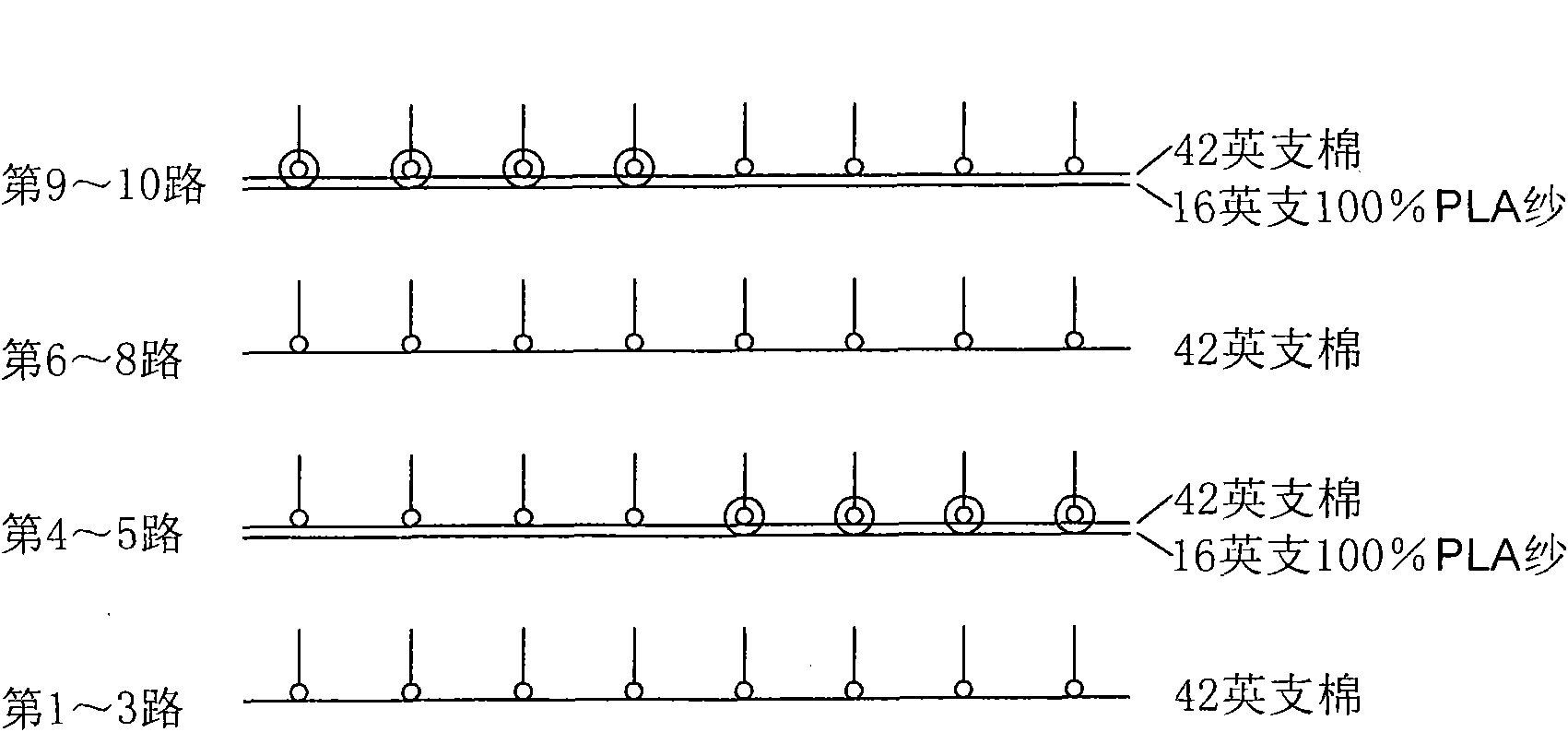

[0032] The fabric coil structure of embodiment 1 is as figure 2 shown, and press image 3 Weave shown. The surface layer of the fabric is woven with 42-count cotton yarn, and the inner layer is woven with 16-count PLA yarn, and the raised structure is floating thread. In a complete weave of a fabric: the surface layer has 10 rows and 8 columns, so the total area of the fabric is 80 flat stitches; the floating thread as a raised structure spans a total of 16 flat stitches, because the width of the floating thread is PLA yarn The diameter of the thread is less than half of the height of the plain stitch loop, so the area covered by the floating thread is 8 plain stitches; the area of the fabric that PLA yarn participates in weaving is 8 plain stitches covered by the floating thread and 16 of the plated weave. Flat stitches, 24 flat stitches in total. Therefore, the raised area accounts for 10% of the total fabric area, and the fabric area where the PLA yarn participates ...

Embodiment 2

[0034] Repeat Example 1, the only difference is that the 16 British count PLA yarns in the weaving inner layer are replaced by 300D polyester low elastic yarns, and the floating threads are stretched during weaving. In a complete fabric weave: the total area of the fabric is 80 flat stitches; the width of the floating line formed by 300D polyester low stretch yarn is 1.5 flat stitches, so the area covered by the floating line is 24 flat stitches; 300D polyester low stretch yarn The area covered by the fabric involved in weaving is 40 flat stitches. Therefore, the raised area accounts for 30% of the total fabric area, and the 300D polyester low elastic yarn participates in the weaving of the fabric area accounts for 50% of the total fabric area. Since the height of the bulge formed by the 300D polyester low elastic yarn is not fixed, it is related to the stretching length of the floating thread during weaving, so the height of the fabric bulge is 1.0mm according to the actual...

Embodiment 3

[0036] The fabric coil structure of embodiment 3 is as Figure 4 shown, and press Figure 5 Weave shown. The surface layer of the fabric is woven with 32-inch cotton yarn, and the inner layer is woven with 16-inch PLA yarn. The raised structure is a large-gauge flat stitch. The vertical and horizontal needle spacing of the inner layer are 4 times and 5 times that of the surface layer, respectively. In a complete fabric weave: the surface layer is 4 rows and 5 columns, so the total area of the fabric is 20 flat stitches; the area covered by the raised structure is 6.5 flat stitches (2.5 flat stitches in the horizontal direction and 4 flat stitches in the vertical direction) needles); the fabric area where the PLA yarn participates in weaving coincides with the area of the raised structure, which is also 6.5 flat stitches. Therefore, the raised area accounts for 32.5% of the total fabric area, and the fabric area where the PLA yarn participates in weaving accounts for 32.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com