Hybrid operation machine

A working machine, hybrid technology, applied in mechanical equipment, liquid variable capacity machines, elevators, etc., can solve the problems of DC bus damage, buck-boost converter damage, etc., and achieve the effect of improving reliability and suppressing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, an embodiment of a hybrid working machine using the present invention will be described.

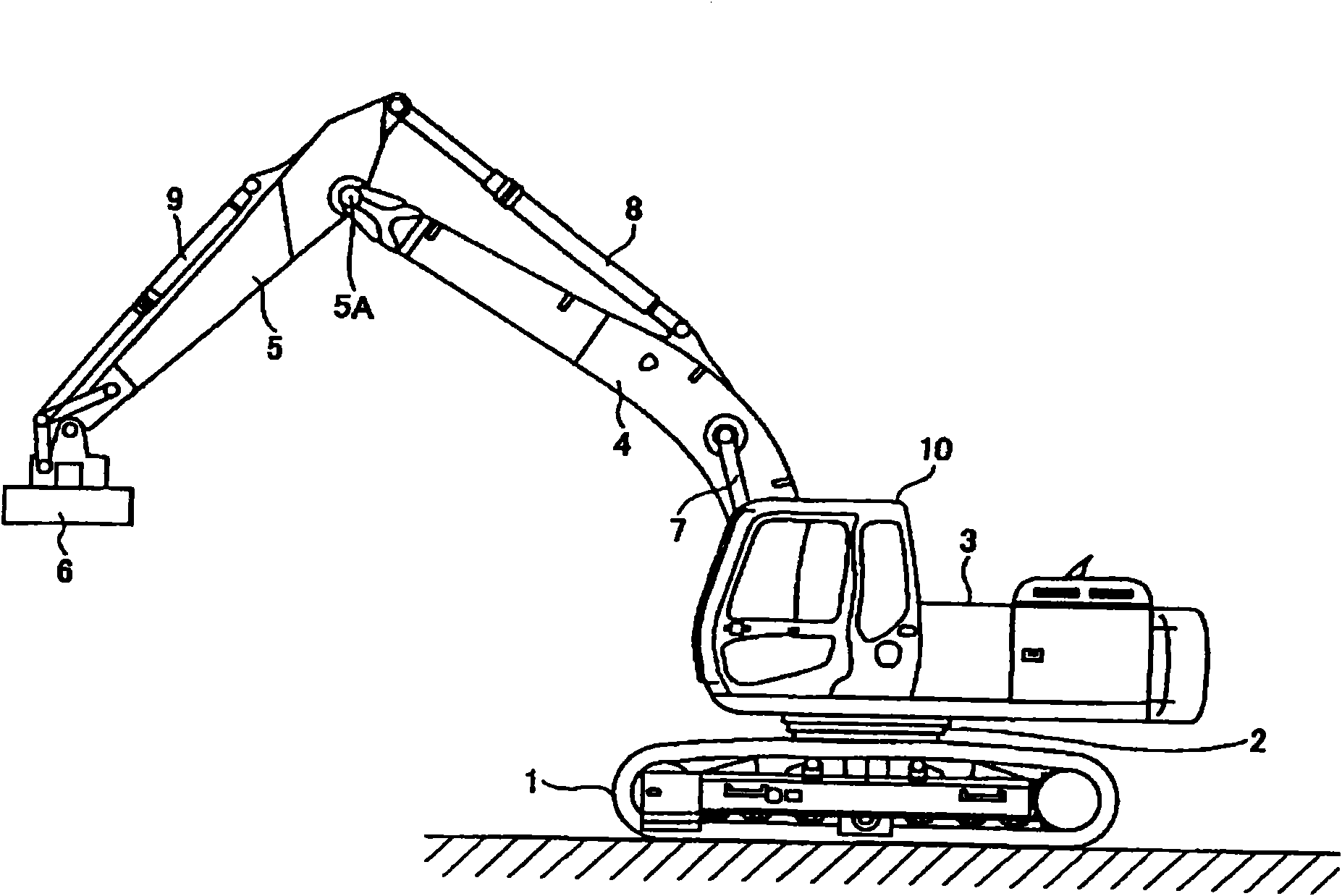

[0075] figure 1 It is a side view showing a construction machine including the hybrid working machine of the present embodiment.

[0076] A revolving upper body 3 is mounted on an undercarriage 1 of this hybrid working machine via a revolving mechanism 2 . In addition, on the upper revolving body 3, in addition to the boom 4, the arm 5, and the lifting electromagnet 6, and the boom cylinder 7, the arm cylinder 8, and the bucket cylinder 9 for hydraulically driving them, a Cockpit 10 and power source.

[0077] [overall composition]

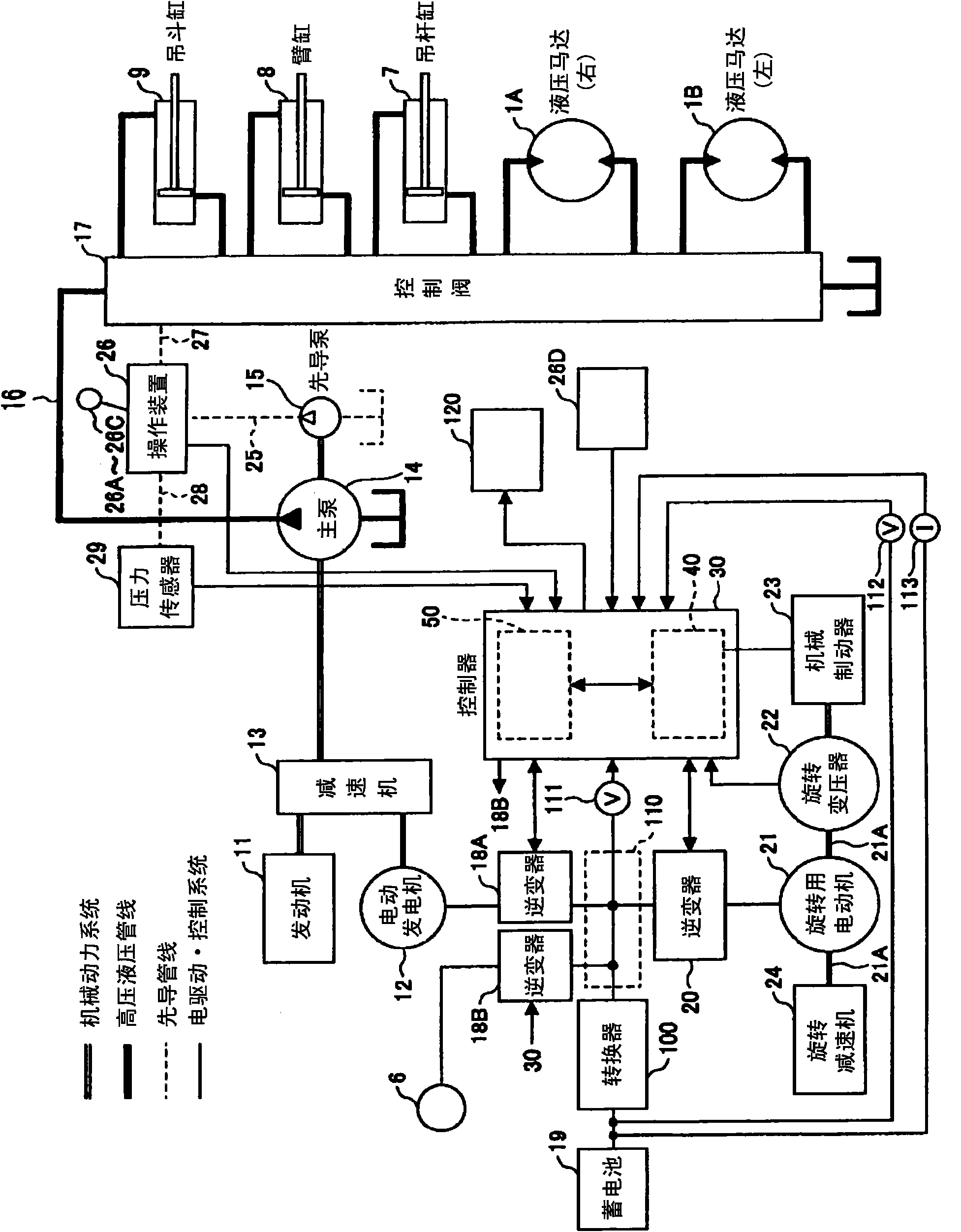

[0078] figure 2 It is a block diagram showing the configuration of the hybrid working machine of the present embodiment. in the figure 2 In , the mechanical power system is represented by a double line, the high-pressure hydraulic line is represented by a thick solid line, the pilot line is represented by a dotted line, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com