Converter circuit, and motor drive controller equipped with converter circuit, air conditioner, refrigerator, and induction cooking heater

A converter circuit and converter technology, applied in the direction of AC motor control, induction heating, induction heating control, etc., can solve the problems that the circuit cannot be small and light, and achieve the effect of reducing switching loss and reducing inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

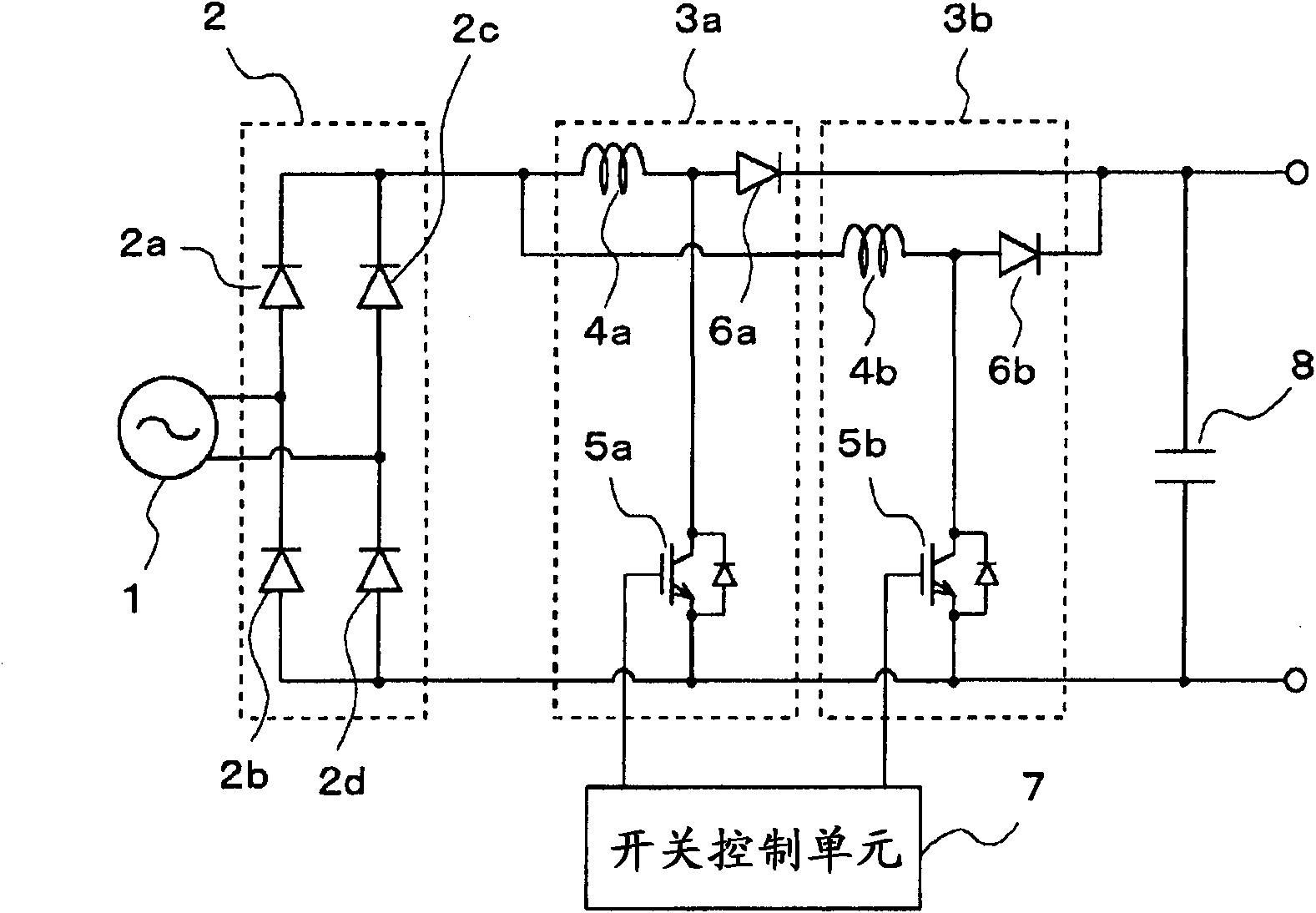

[0030] figure 1 It is a block diagram of the converter circuit concerning Embodiment 1 of this invention.

[0031] exist figure 1 Among them, the rectifier 2 for rectifying the AC voltage of the commercial power supply 1 has a structure in which four rectifier diodes 2a to 2d are connected in bridge form. To the output of the rectifier 2, a boost converter 3a as a first converter unit and a boost converter 3b as a second converter unit are connected in parallel.

[0032] The boost converter 3a is composed of: a boost reactor 4a as a first reactor; and a switching element 5a as a first switching element, for example, an IGBT (Insulated Gate Bipolar Transistor: Insulated Gate Bipolar Transistor) or the like. ; and the backflow prevention element 6a as the first backflow prevention unit is composed of, for example, a fast recovery (fast recovery) diode or the like. In addition, the boost converter 3b is also composed of the following parts in the same manner: a boost reactor 4...

Embodiment approach 2

[0068] In the first embodiment described above, the current mode of the current flowing through the boost reactor 4 is set to be the critical mode or the discontinuous mode by operation. In Embodiment 2, by switching the current mode during operation, operations utilizing the characteristics of each current mode can be performed.

[0069] Here, the characteristics of each current mode will be described.

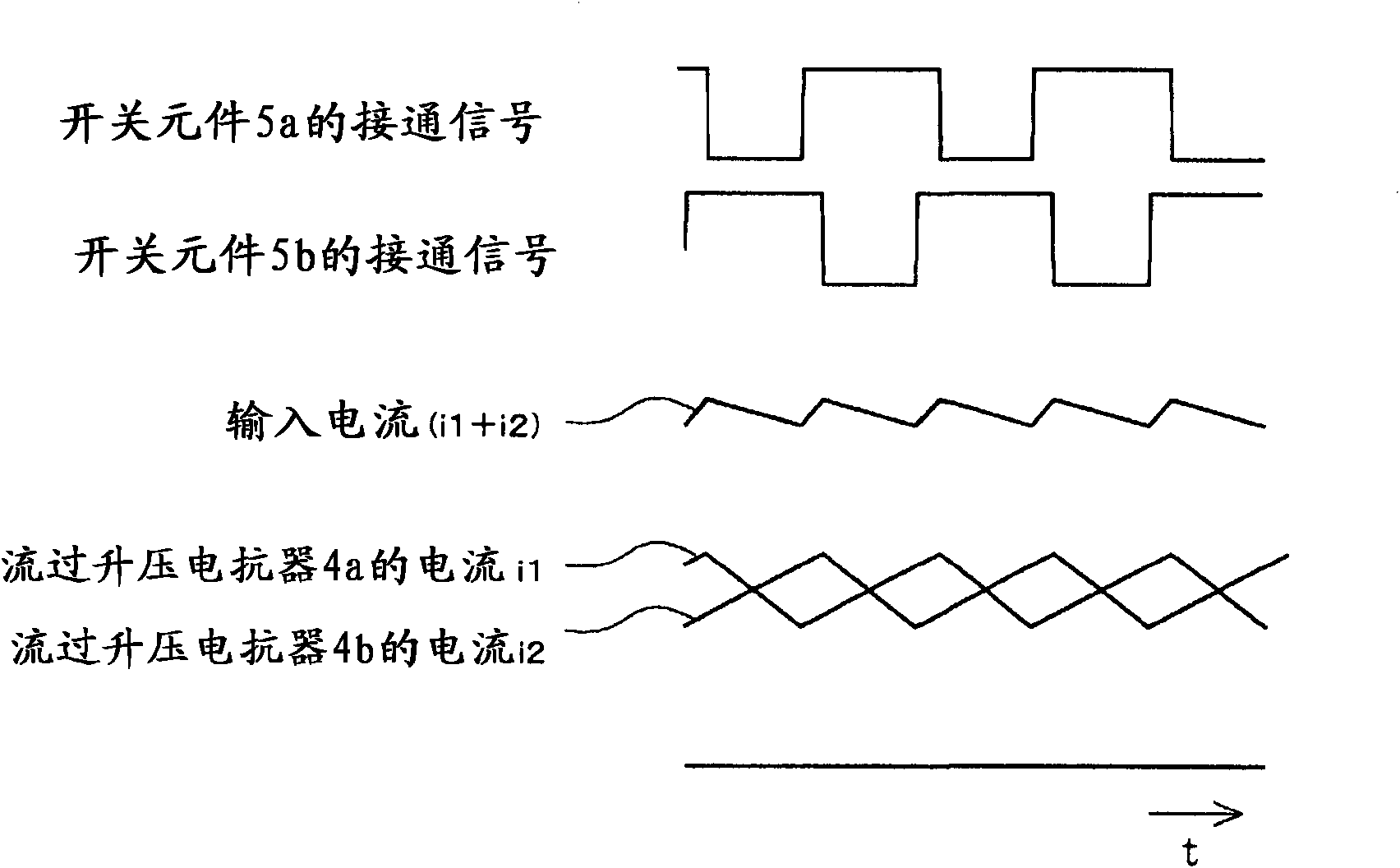

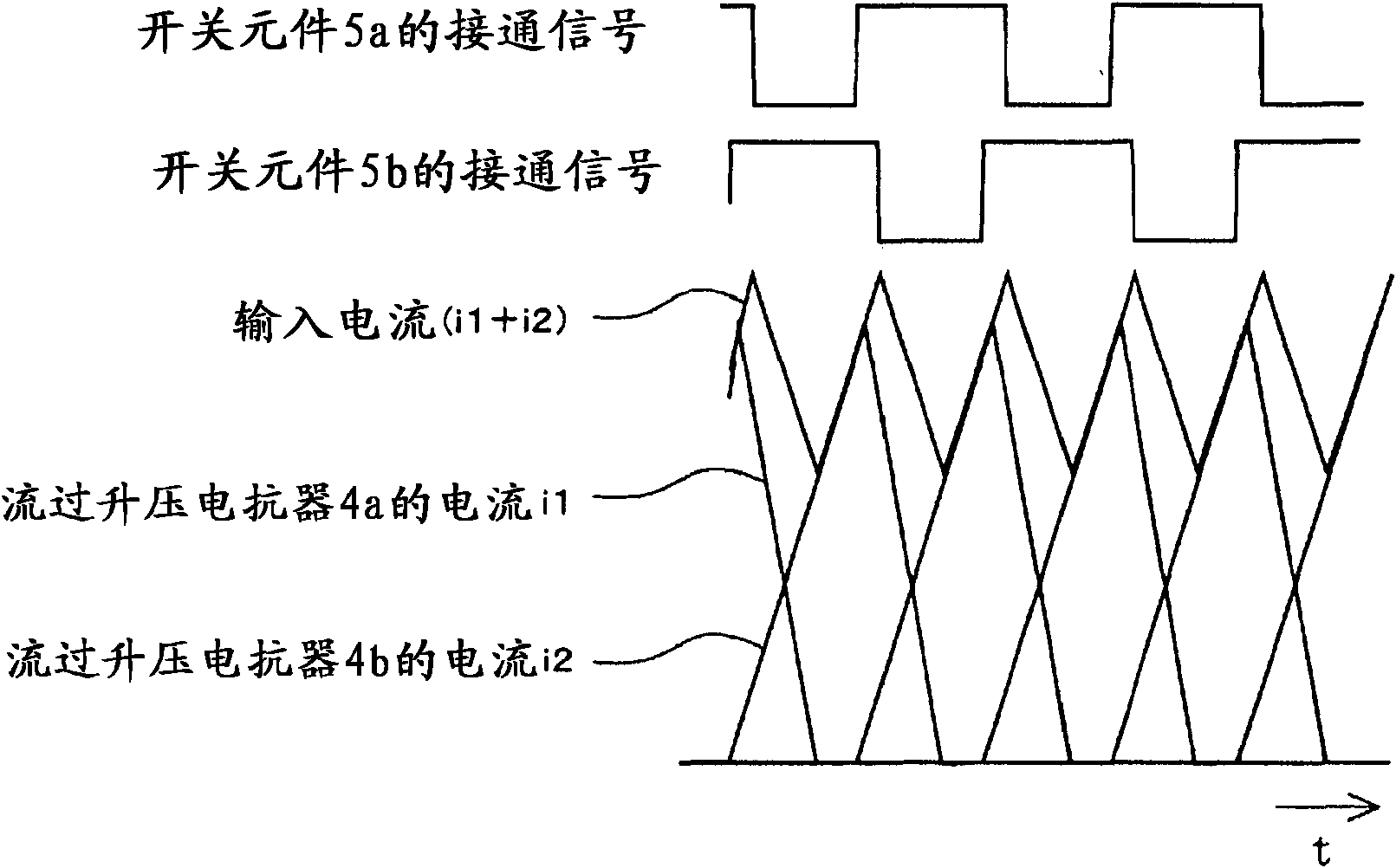

[0070] In the case of controlling in the continuous mode, compared with the critical mode and the discontinuous mode, the current ripple rate is small, and the generation of harmonic components of the input current can be suppressed. On the other hand, since the switching frequency becomes higher than in the critical mode and the discontinuous mode, the switching loss in the switching element 5 and the backflow prevention element 6 becomes large.

[0071] In the case of operating in the critical mode, the current ripple rate is smaller than that in the discontinuous mode, an...

Embodiment approach 3

[0120] In Embodiment 1 or 2 above, a case where two boost converters are used has been described, but in Embodiment 3, three or more boost converters are used.

[0121] Figure 9 It is a configuration diagram of a converter circuit according to Embodiment 3 of the present invention.

[0122] Such as Figure 9 As shown, the converter circuit in the third embodiment includes a boost converter 3c connected in parallel to the boost converters 3a and 3b in addition to the configuration of the above-mentioned first embodiment.

[0123] Similarly, the boost converter 3c is composed of: a boost reactor 4c as a reactor in the present invention; a switching element 4c as a switching element in the present invention, for example, is composed of an IGBT or the like; The backflow prevention element 6c of the backflow prevention element in the present invention is constituted by, for example, a fast recovery diode or the like.

[0124] In addition, other structures are the same as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com