Composite flame retardant with core-shell structure and preparation method thereof

A technology of composite flame retardant and shell structure, which is applied in the field of core-shell structure composite flame retardant and its preparation, can solve the problems of reduced flame retardant performance and reduced expansion volume, and achieve improved flame retardant performance and increased expansion volume , strong operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

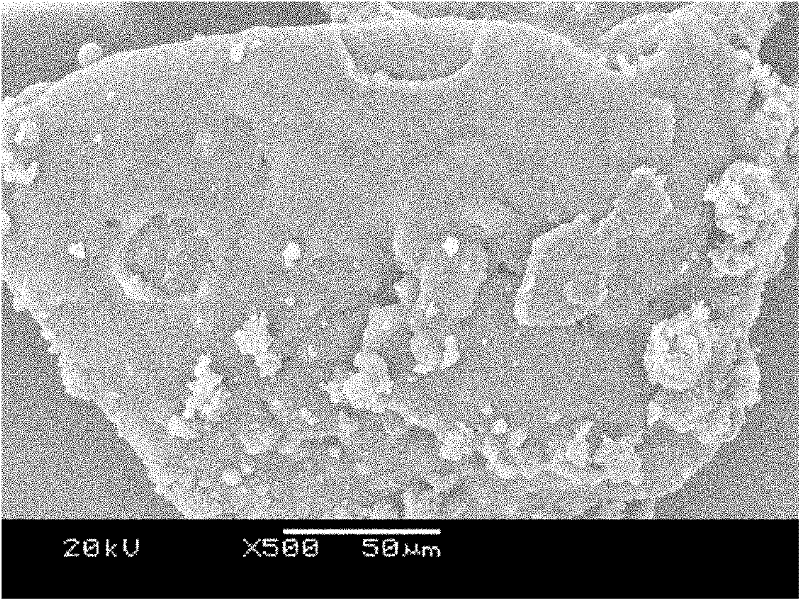

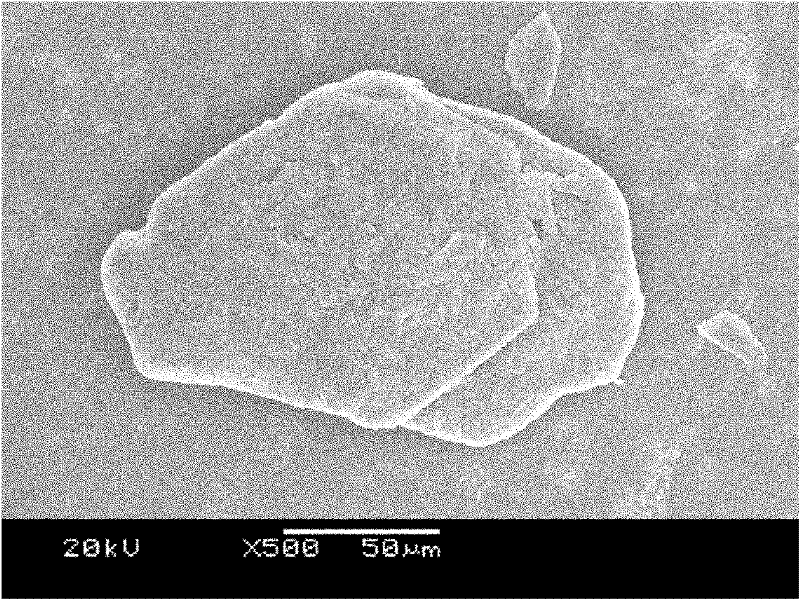

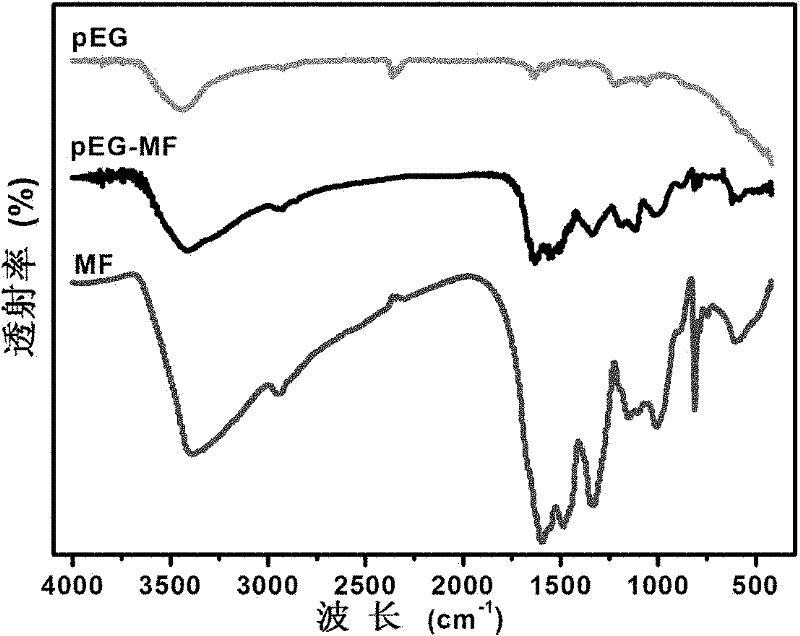

[0029] 1) First add melamine to water to prepare an aqueous solution with a concentration of 20% by weight, then use a 10% NaOH solution to adjust the pH value of the aqueous solution to 9, heat up to 50°C, stir and reflux for at least 30 minutes, then add formaldehyde solution, and reflux at a constant temperature After reacting for 13 minutes, a clear solution was obtained, and the molar ratio of melamine and formaldehyde added was 1:5.

[0030] 2) Add expandable graphite with an average particle size of 120 μm into water, disperse for 30 min under ultrasonic stirring, prepare an expandable graphite suspension aqueous solution with a concentration of 40% by weight, and make the mass ratio of expandable graphite to melamine 2.5: 1;

[0031] 3) Pour the clear solution obtained in step 1) into the suspension obtained in step 2), first raise the temperature to 50° C. and stir and reflux for at least 30 minutes, then adjust the pH value to 3 with 10% acetic acid solution, and sti...

Embodiment 2

[0034] 1) First add melamine to water to prepare an aqueous solution with a concentration of 5% by weight, then adjust the pH value of the aqueous solution to 8 with a KOH solution with a concentration of 10%, raise the temperature to 50°C, stir and reflux for at least 30 minutes, then add formaldehyde solution, and reflux at a constant temperature After reacting for 15 minutes, a clear solution was obtained, and the molar ratio of melamine and formaldehyde added was 1:4;

[0035]2) Add expandable graphite with an average particle diameter of 100 μm into water, disperse for 30 min under ultrasonic stirring, prepare an expandable graphite suspension aqueous solution with a concentration of 40% by weight, and make the mass ratio of expandable graphite to melamine 3: 1;

[0036] 3) Pour the clear solution obtained in step 1) into the suspension obtained in step 2), first raise the temperature to 50° C. and stir and reflux for at least 30 minutes, then adjust the pH value to 3 wit...

Embodiment 3

[0039] 1) First add melamine to water to prepare an aqueous solution with a concentration of 9.1% by weight, then adjust the pH of the aqueous solution to 9 with a 10% KOH solution, heat up to 65°C, stir and reflux for at least 30 minutes, then add formaldehyde solution, and reflux at a constant temperature After reacting for 10 minutes, a clear solution was obtained, and the molar ratio of melamine and formaldehyde added was 1:3.

[0040] 2) Add expandable graphite with an average particle diameter of 150 μm into water, disperse for 30 min under ultrasonic stirring, prepare an expandable graphite suspension aqueous solution with a concentration of 30% by weight, and make the mass ratio of expandable graphite to melamine 4: 1;

[0041] 3) Pour the clear solution obtained in step 1) into the suspension obtained in step 2), first raise the temperature to 65° C., stir and reflux for at least 30 minutes, then adjust the pH value to 4 with 10% acetic acid solution, and stir for 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com