High pressure resistant drilled hole sealing method

A high-pressure-resistant technology to be drilled, used in sealing/isolation, earth-moving, wellbore/well components, etc., and can solve problems such as changes in coal gas permeability, loose coal, and poor hole sealing. Achieving the effect of wide practicability, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

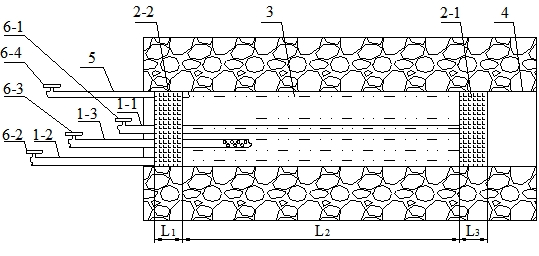

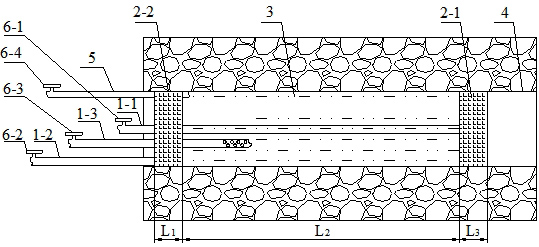

[0015] In the high-pressure-resistant borehole sealing method of the present invention, first, insert the first grouting pipe 1-1 into the drilled hole 4 that has been constructed in the coal seam with a construction depth of more than 40m and an aperture diameter of φ113mm; Borehole 4 is injected at a depth of 27-29m into I grouting thickness L 3 I high-pressure-resistant sealing material 2-1 of 1~2m, and high-strength sealing material 2-1 is an expansive cement jelly material with a compressive strength greater than 30MPa. Ⅰ Grouting thickness L 3 After injection, close the ball valve 6-1; insert the second grouting pipe 1-2 with a depth of 1-2m and the third grouting pipe 1-3 with a depth of 5-6m into the borehole 4, respectively. The grouting pipe 5 at the top and with a depth of 2-3m, all the grouting pipe front-end pipe walls are provided with 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com