Rectification-type self-overlaying gas liquefying system

A self-cascading and rectifying technology, used in refrigeration and liquefaction, fluid circulation arrangement, lighting and heating equipment, etc. problems, to achieve the effect of reducing unit liquefaction work, ensuring reliable operation, and reducing heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

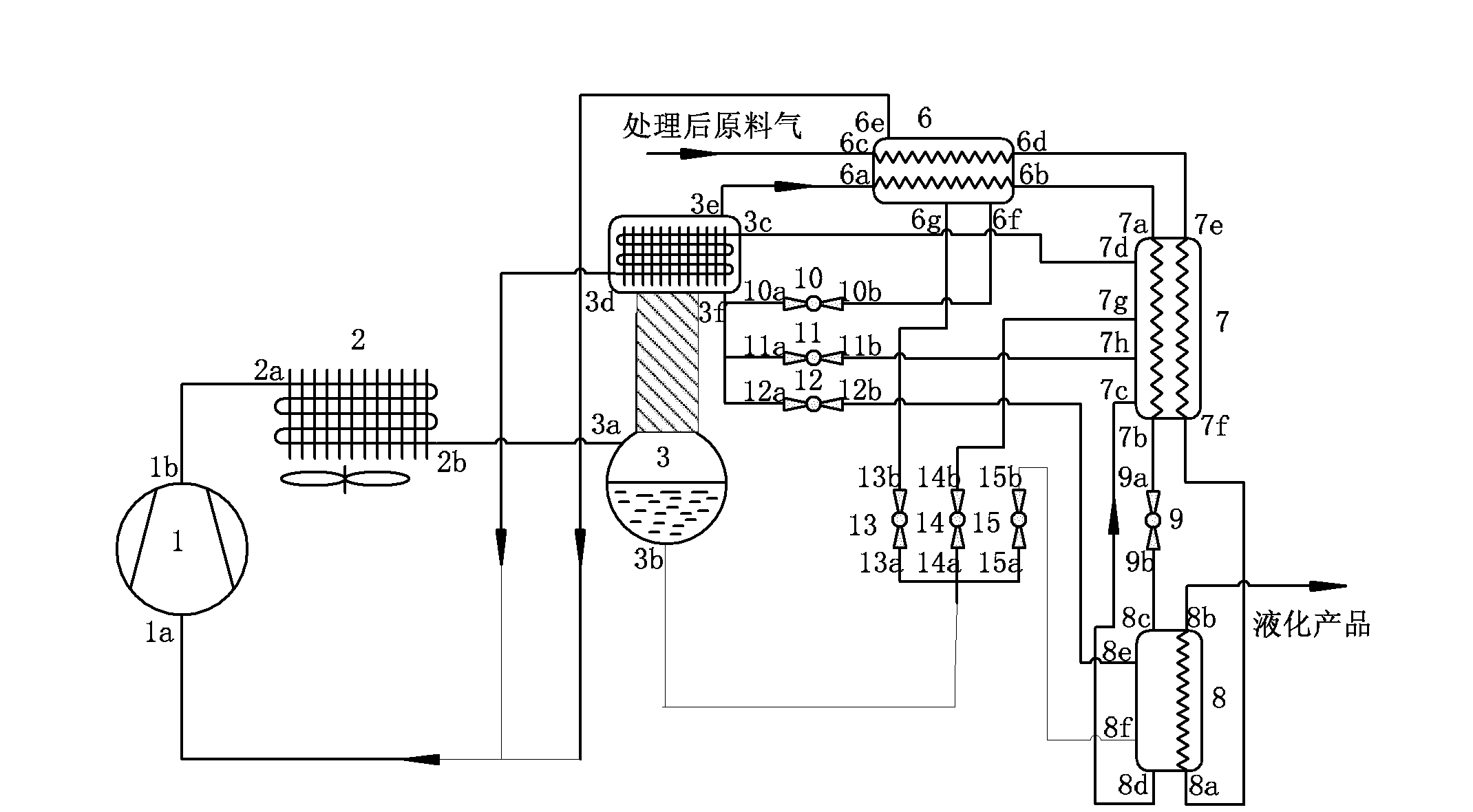

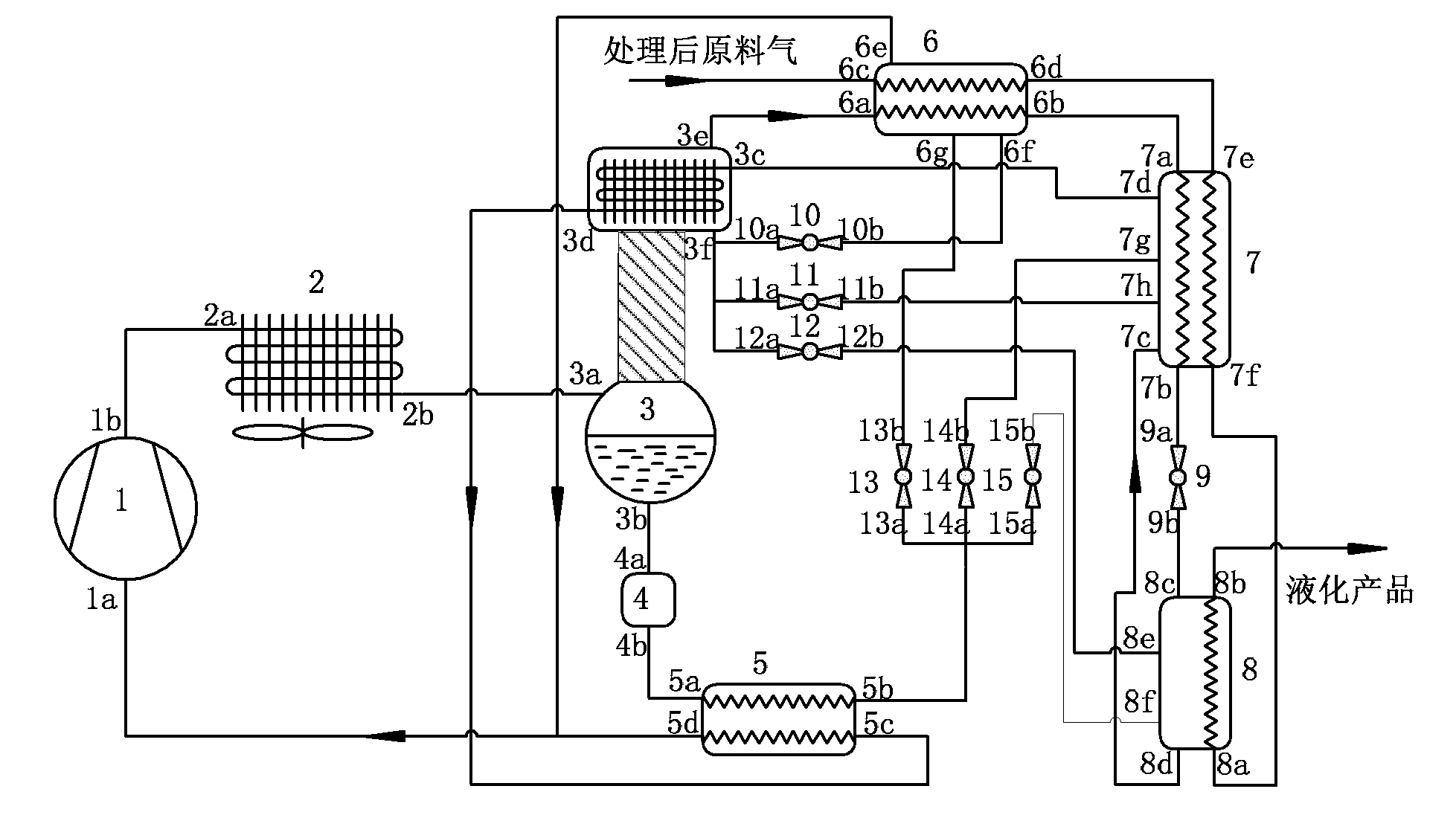

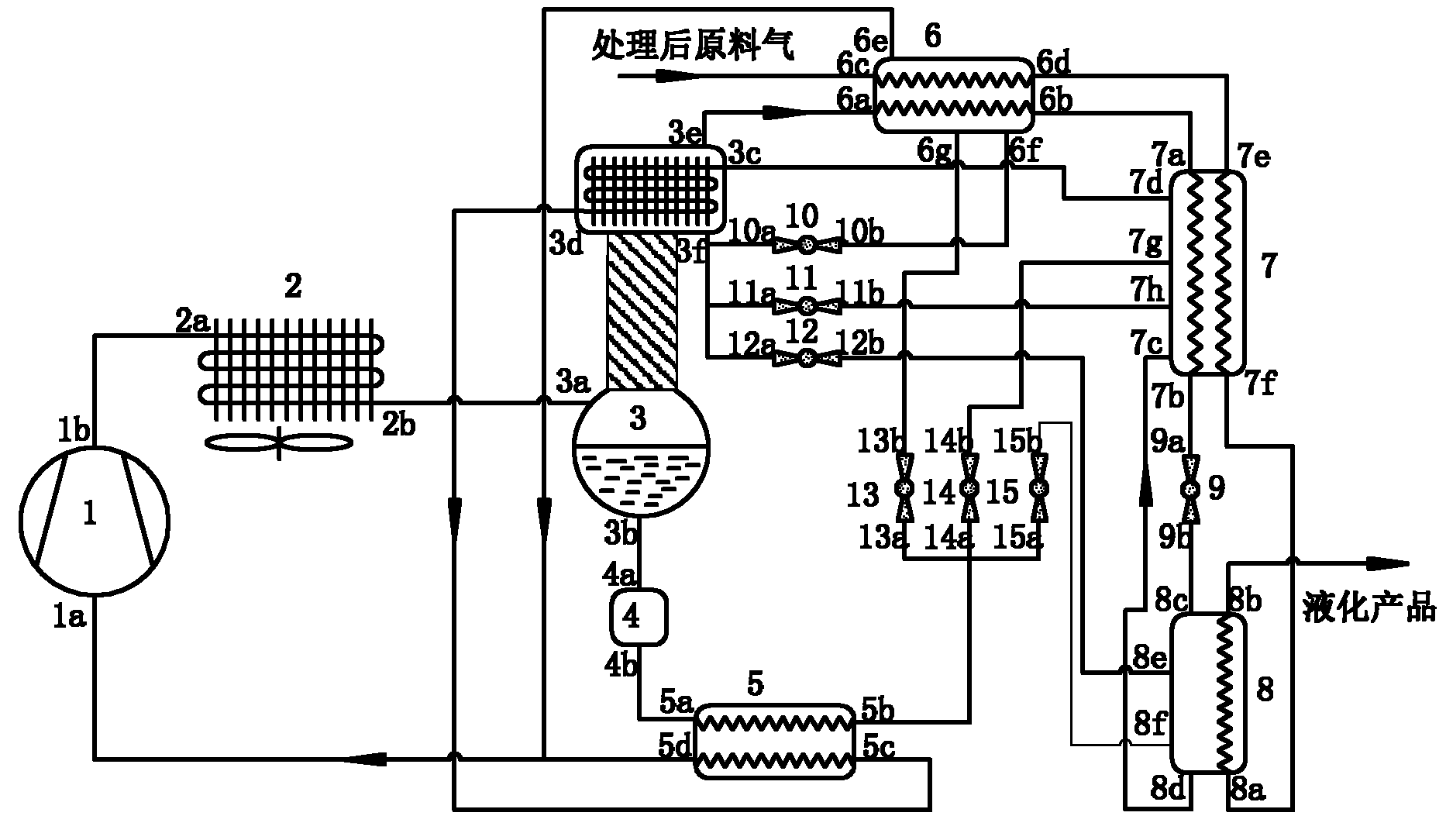

[0023] as attached figure 1 As shown, a rectification type self-cascading gas liquefaction system includes a compressor 1, a condenser 2, a rectification device 3, a first heat exchanger 6, a second heat exchanger 7, a third heat exchanger 8, The first throttle element 9 , the second throttle element 10 , the third throttle element 11 , the fourth throttle element 12 , the fifth throttle element 13 , the sixth throttle element 14 , and the seventh throttle element 15 . The rectification device 3 includes a rectification tower and a tower top heat exchanger communicated with the top of the rectification section of the rectification tower. Both the first heat exchanger 6 and the second heat exchanger 7 are provided with a refrigerant pipeline and a raw material gas liquefaction pipeline, and a plurality of feeding or discharging ports communicating with the inner cavity are arranged on the outer wall. The third heat exchanger 8 is provided with a feed gas liquefaction pipeline,...

Embodiment 2

[0040] The only difference from Example 1 is that a dry filter 4 and a tank bottom heat exchanger 5 are provided between the bottom of the rectification column and the fifth throttling element 13 or the sixth throttling element 14 or the seventh throttling element 15 . Wherein, the liquid outlet 3b at the bottom of the rectifying tower of the rectifying device 3 is connected to the feed port 4a of the dry filter 4 earlier, and the discharge port 4b of the dry filter 4 is connected to one of the pipes in the heat exchanger 5 at the bottom of the tank. The inlet end 5a is connected, and the outlet end 5b of the pipeline is connected with the feed port of the fifth throttling element 13 or the sixth throttling element 14 or the seventh throttling element 15 respectively; The inlet end 5c of a pipeline is connected, and the outlet end 5d of this pipeline is communicated with the suction port 1a of the compressor 1; On both sides of the pipe, ensure the reverse flow of materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com