Power detection method of engine of construction machinery and device thereof

A technology for construction machinery and power detection, applied in the direction of measuring devices, power metering, instruments, etc., can solve the problems of inconvenient installation and maintenance, increased cost, high cost, etc., achieve stable and reliable work, reduce installation space, and be easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

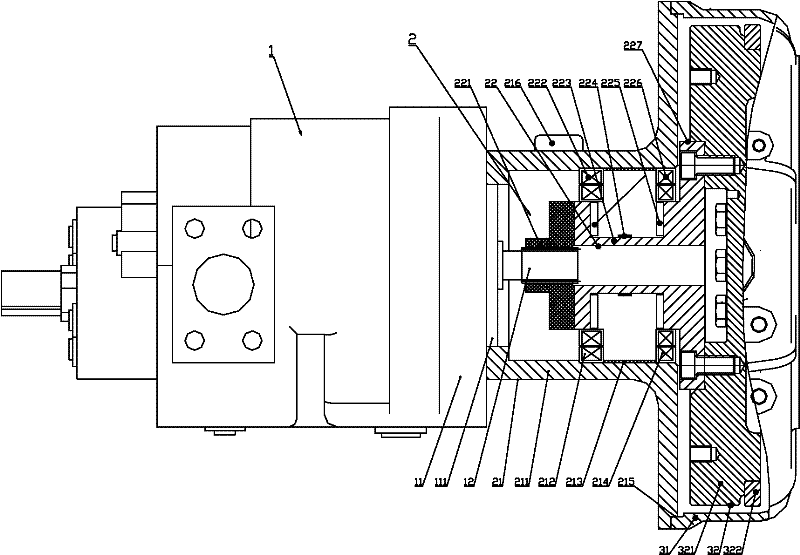

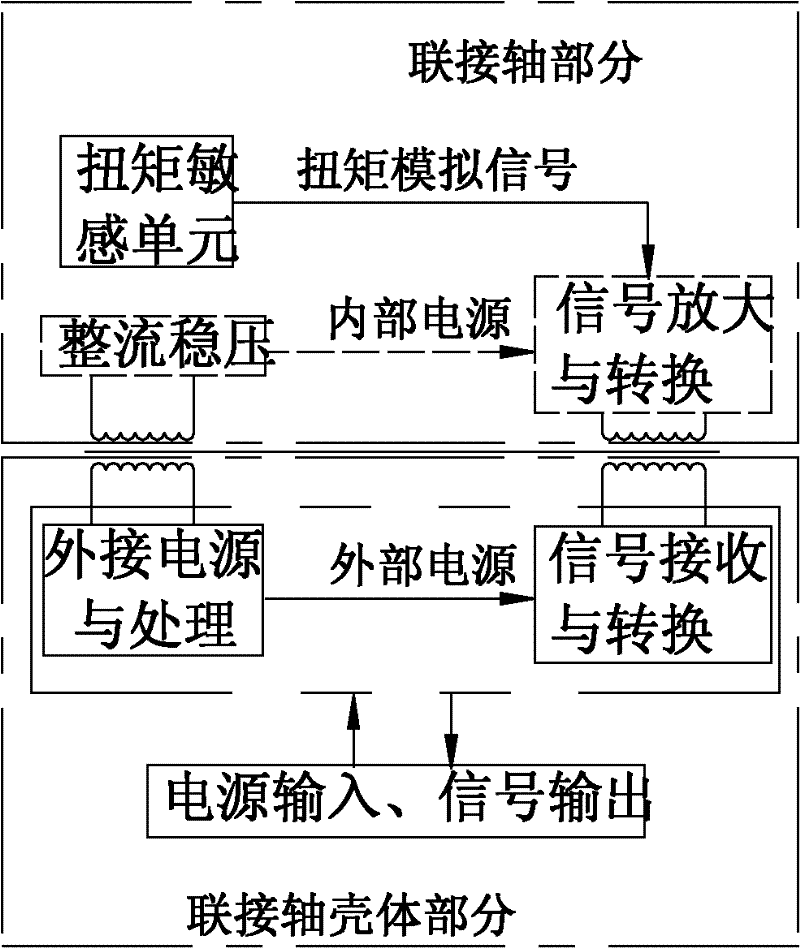

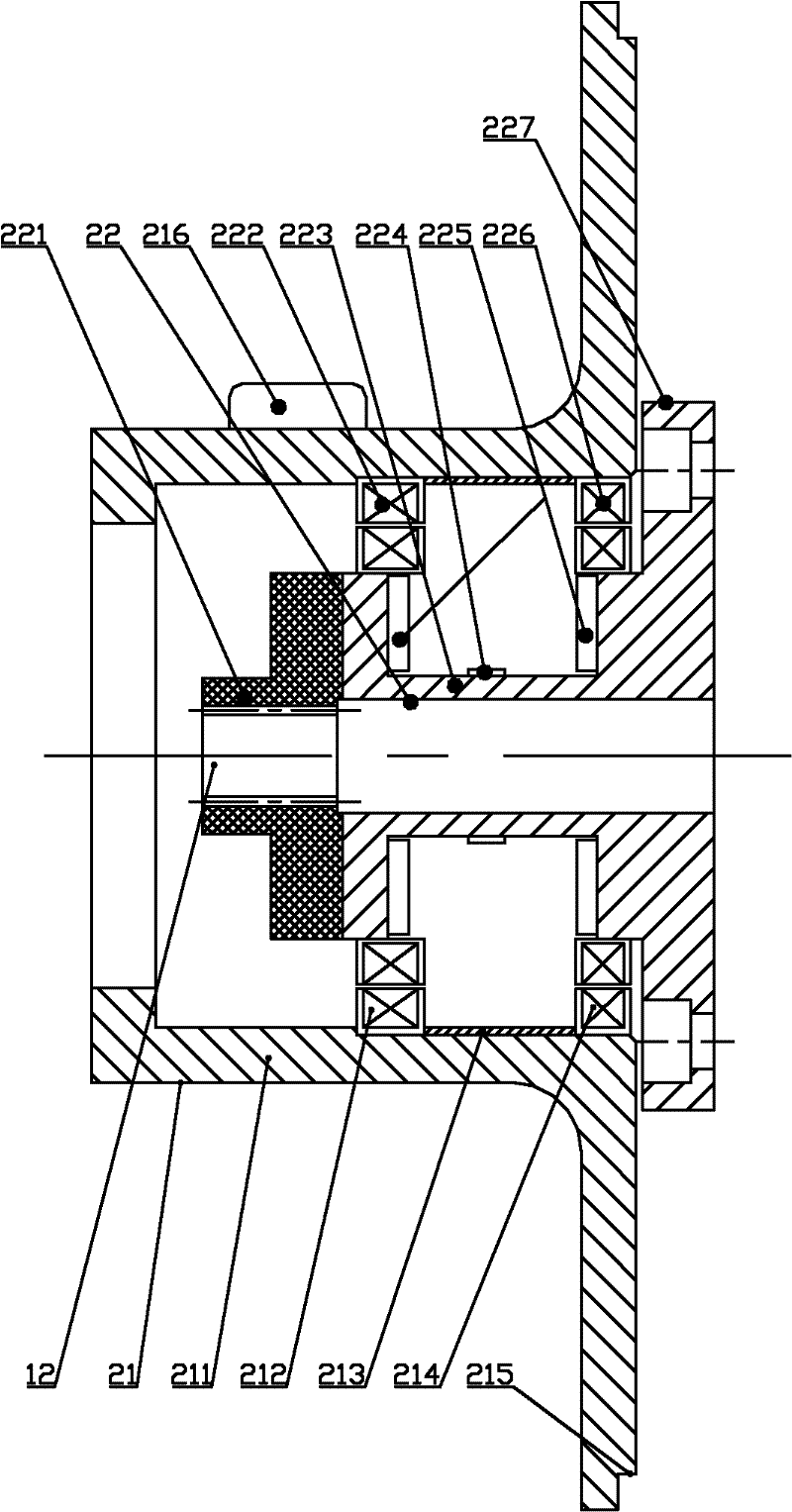

[0037] figure 1 It is a schematic diagram of the installation and connection of the device with the engine and the hydraulic pump. In the figure, the flywheel housing and the hydraulic pump housing connecting flange of the engine are respectively connected to the two ends of the power detection device connecting housing through the hydraulic pump housing connecting flange positioning flange and the connecting housing positioning flange. The power output is output from the engine's crankshaft through the engine flywheel, and the hydraulic pump receives the driving power of the engine by its drive shaft. in figure 1 Both ends of the connecting shaft of the mid-power detection device are respectively connected with the engine flywheel 321 and the hydraulic pump drive shaft 12, and bear the torsion of the engine output torque during power transmission, thereby causing the stress change or torsion deformation of the connecting shaft 223. In the existing torque sensor technology, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com