Application method of object manufacture defect

An application method and defect technology, applied in the application field of object manufacturing defects, can solve problems such as misjudgment, and achieve the effect of accurate misjudgment and accurate estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

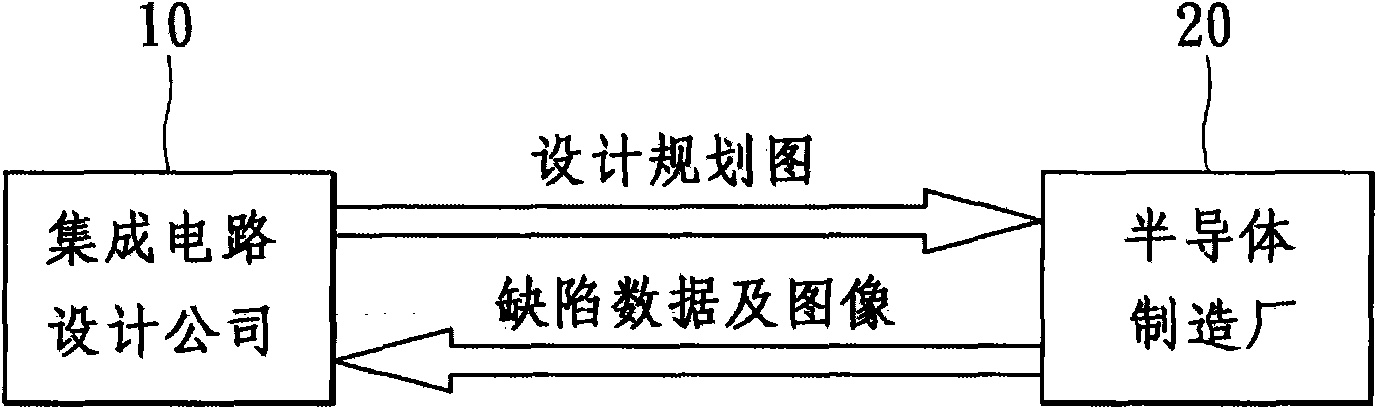

[0065] Besides the first embodiment, the method further has a second preferred embodiment. The second embodiment also takes a wafer as an example of an item, and can be implemented in the design company 10 or the manufacturing plant 20 .

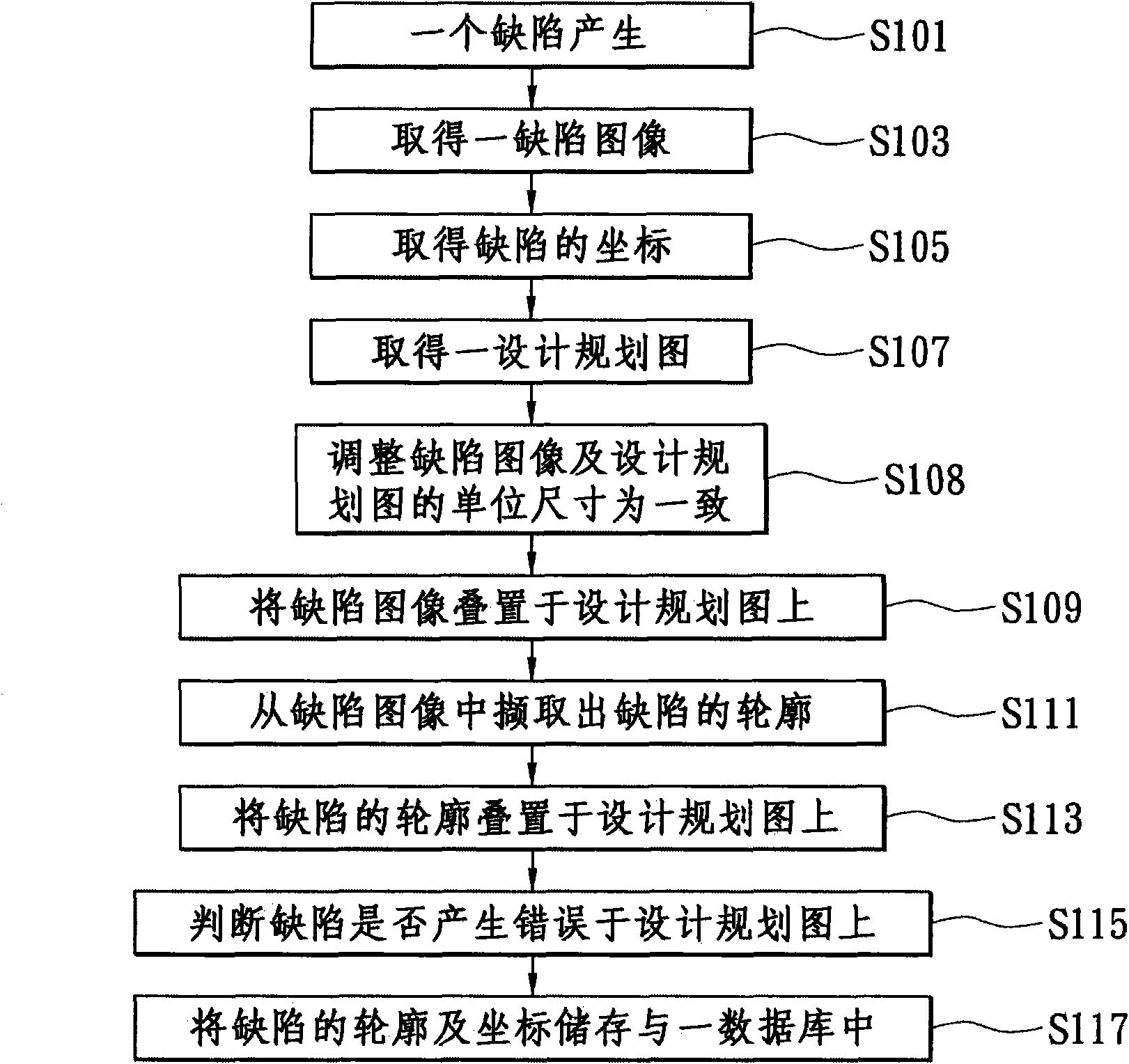

[0066] Please refer to Figure 11 shown, and with reference figure 2 , image 3 and Figure 4 , the detailed flow of the second embodiment of the method is proposed as follows, which is similar to the flow of the first embodiment. That is to say, steps S401 to S407 are the same as steps S101 to S107, and steps S415 to S417 are respectively the same as steps S115 to S117, so the following description will focus on steps S409 and S413.

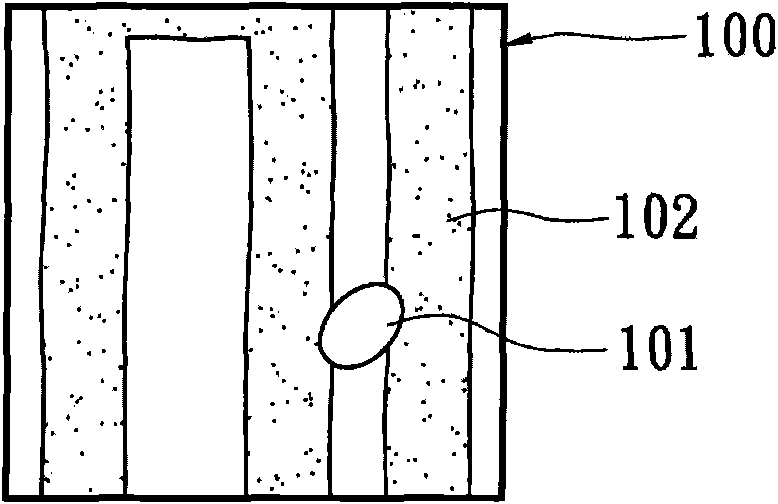

[0067] In step S409 , the defect image 100 will eventually be superimposed on the design plan 200 according to the coordinates of the defect 101 , but it is completed in two detailed steps. Please refer to Figure 12 As shown, first, according to the coordinates of the defect 101, a partial design plan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com