Heating equipment for steam heating mould

A technology of heating equipment and steam, applied in the field of mold manufacturing, can solve the problems of high energy consumption, high mold cost, long production cycle, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

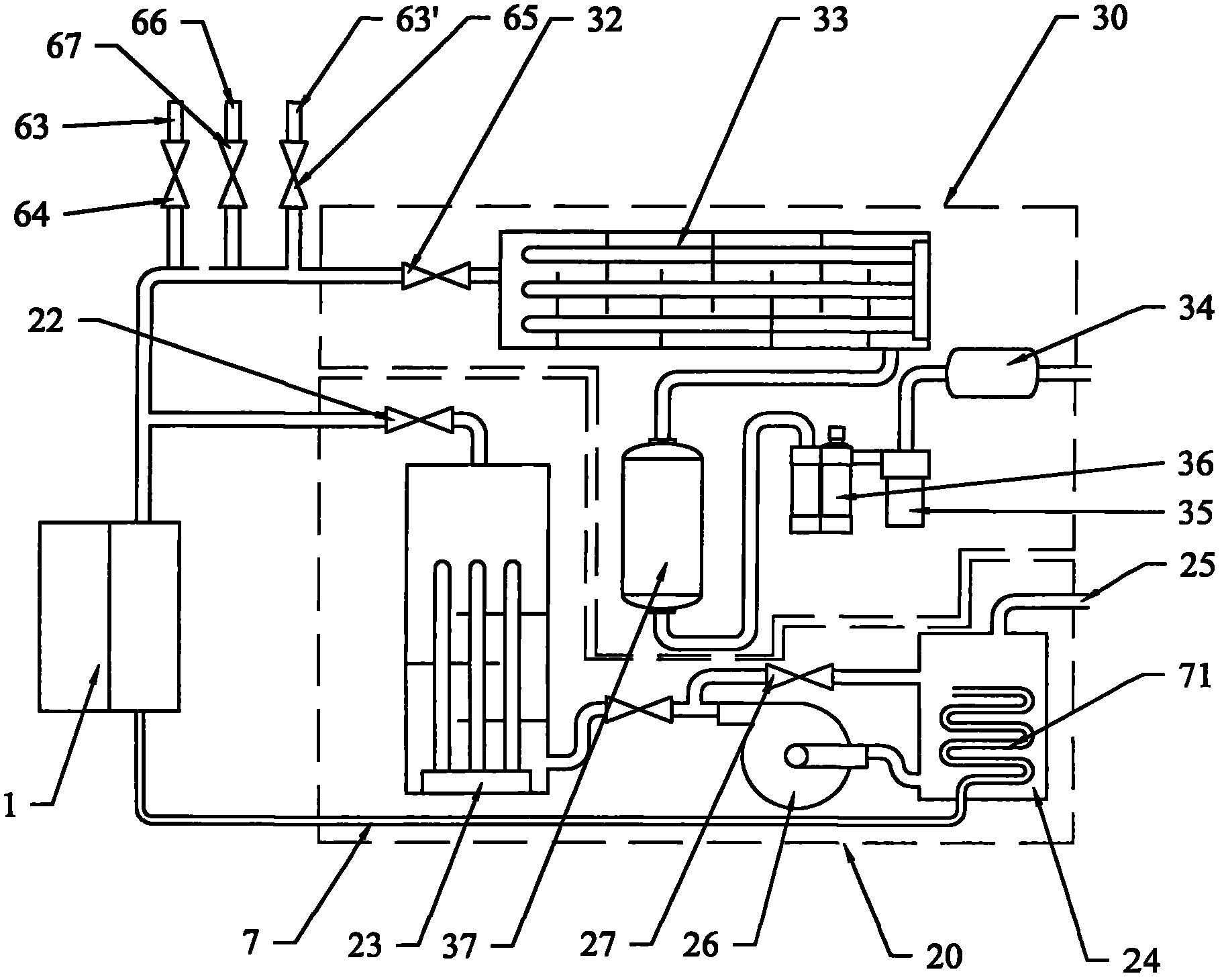

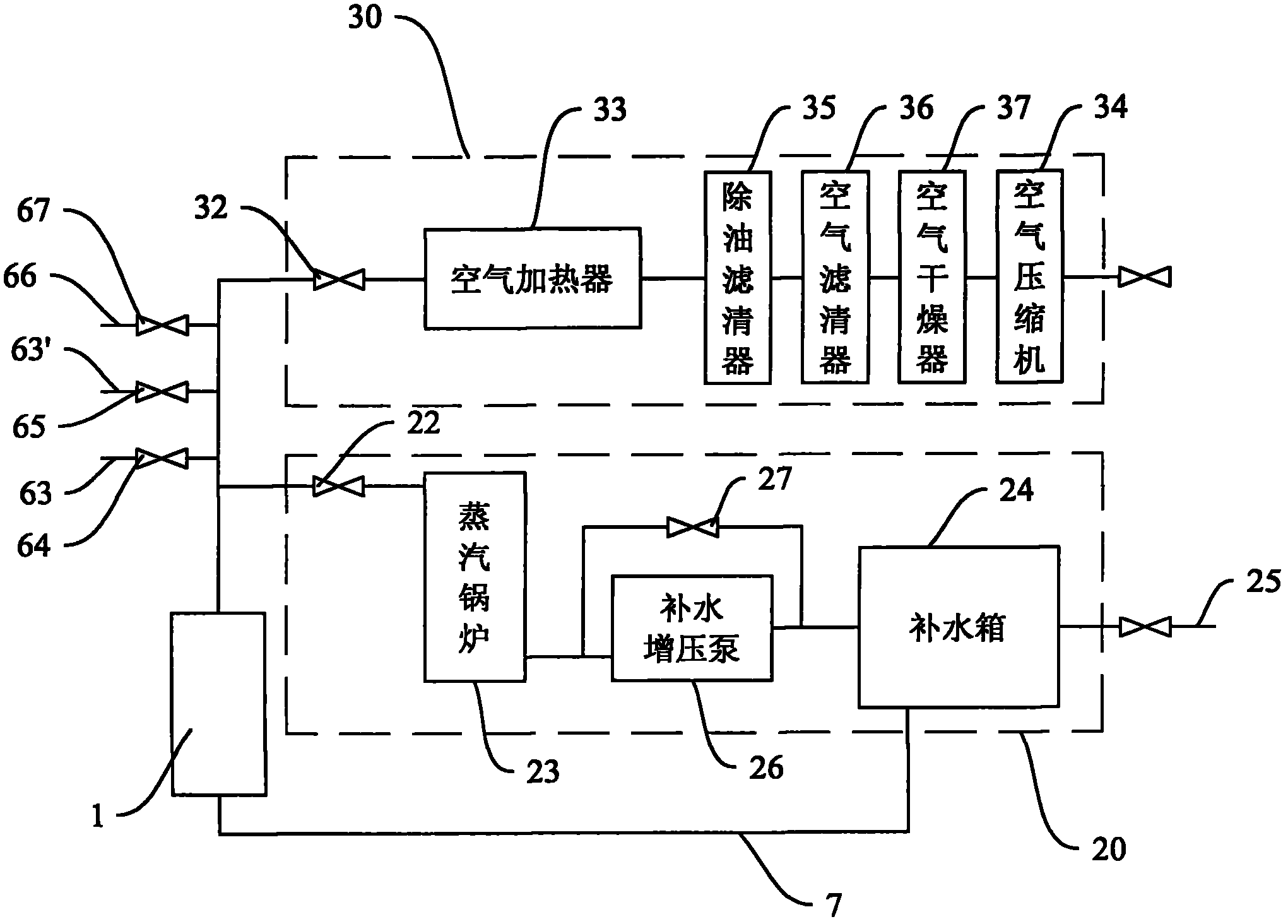

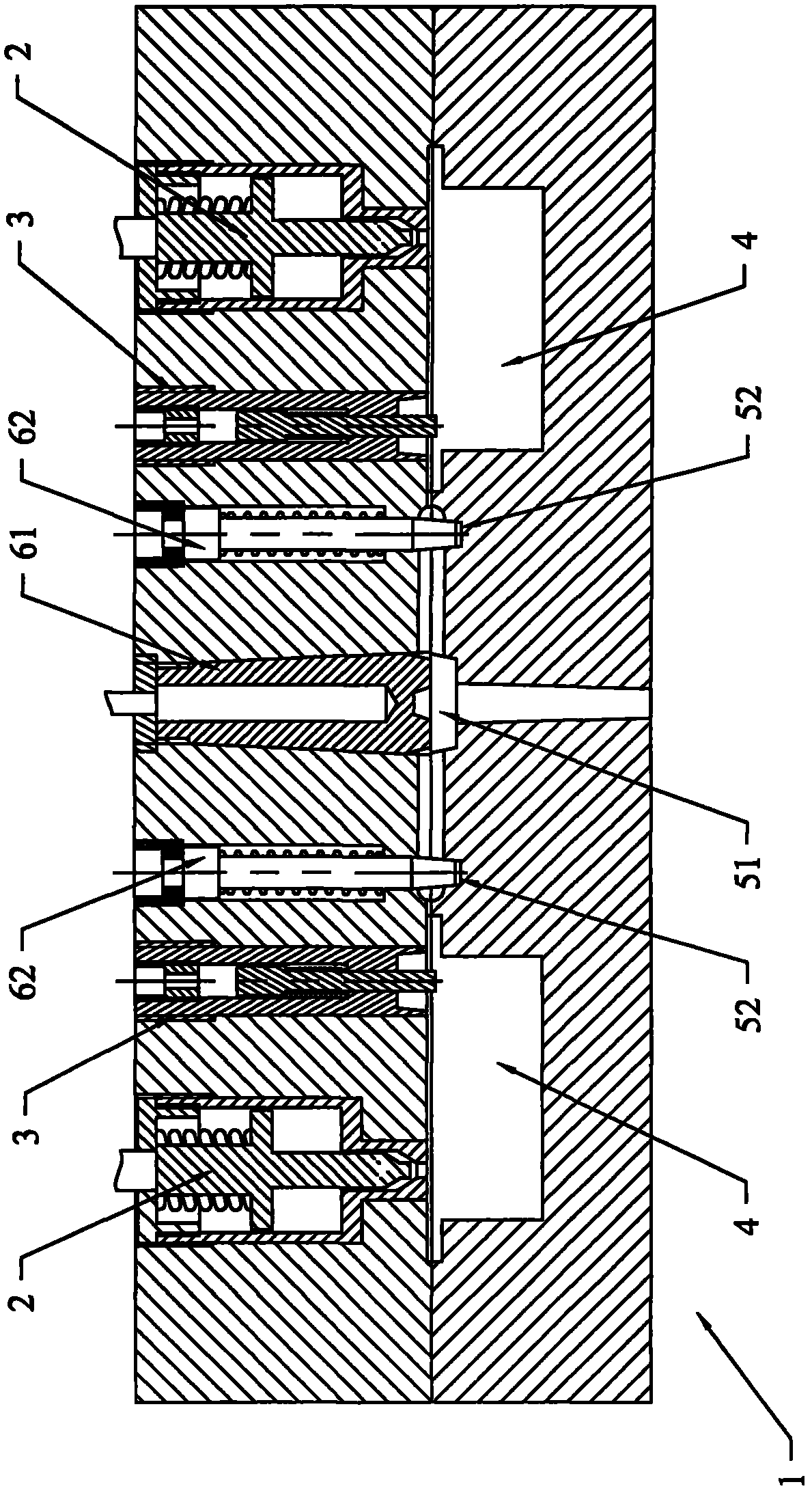

[0029] like figure 1 , 2 , 3, in the heating equipment utilizing steam to heat the mold according to the present invention, it includes a mold core 1, an injection valve 3 and an overflow valve 2 arranged on the mold core 1, a shut-off valve arranged on the mold core runner, a high temperature Steam branch 20 and high temperature dry air branch 30. Wherein, the mold core 1 is provided with runners for injecting raw materials into the mold cavity 4 of the mold core 1 . The injection valve 3 and the overflow valve 2 are arranged on the mold core 1 and communicate with the mold cavity 4, both of which are one-way one-way valves. Injection valve 3 and overflow valve 2 are closed when no high-temperature steam or high-temperature dry air is introduced, so as to ensure that the entire mold cavity 4 is airtight. Depending on the specific mold structure, multiple injection valves 3 and overflow valves 2 can also be provided, at least ensuring that there is one injection valve 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com