Lifting starting and stopping system for rotating gate

A winch and gate technology, applied in the field of winch opening and closing system, can solve the problem of meshing accuracy, tooth surface contact length, large diameter ring gear manufacturing, high installation accuracy, limiting the installation space of the opening and closing mechanism, and increasing manufacturing costs, etc. problem, to achieve the effect of highlighting the substantive features, saving equipment investment, reducing the diameter and length of the reel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

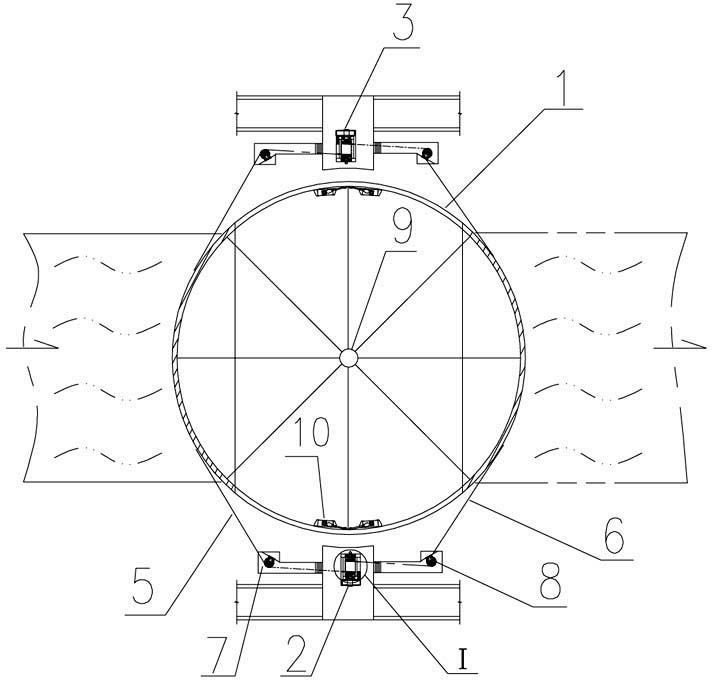

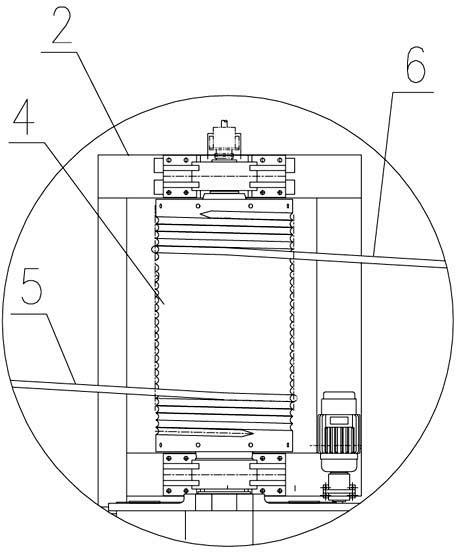

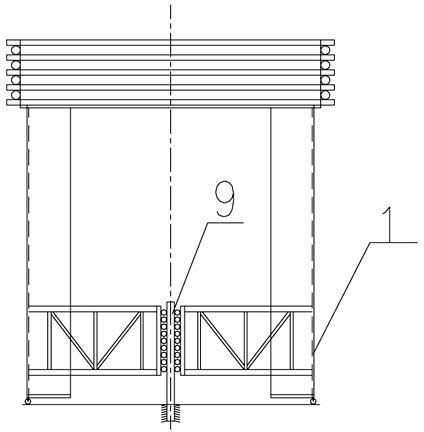

[0016] like figure 1 , 2 As shown in , 3, the hoisting opening and closing system for the rotary gate according to the present invention, it drives the driving mechanism of the cylindrical gate 1 to rotate 180° in both forward and reverse directions; the bottom end of the cylinder shaft 9 of the cylindrical gate 1 The bearing is connected with the bearing seat set on the river bed through the bearing; the lower cylinder mouth of the cylinder gate 1 is connected with the circular track set on the river bed by rolling through the roller. The driving mechanism is the hoisting hoists 2 and 3 arranged in the operation room below the ground on both sides of the river, symmetrical to the cylinder gate 1; The metal core galvanized steel wire ropes 5 and 6 are wound on the reel 4 in opposite directions. The other ends of the two steel wire ropes 5 and 6 are respectively turned through the guide pulleys 7 and 8 arranged in the underground corridor and then passed through the rigging. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com