Non-sticky nonrust iron pan and manufacturing method thereof

A technology of stainless iron pots and iron pots, applied in applications, coatings, kitchen utensils, etc., can solve problems such as dark surface, reduced anti-rust function, and easy breakage, so as to shorten heating time, improve thermal efficiency, and prevent sticking pans Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

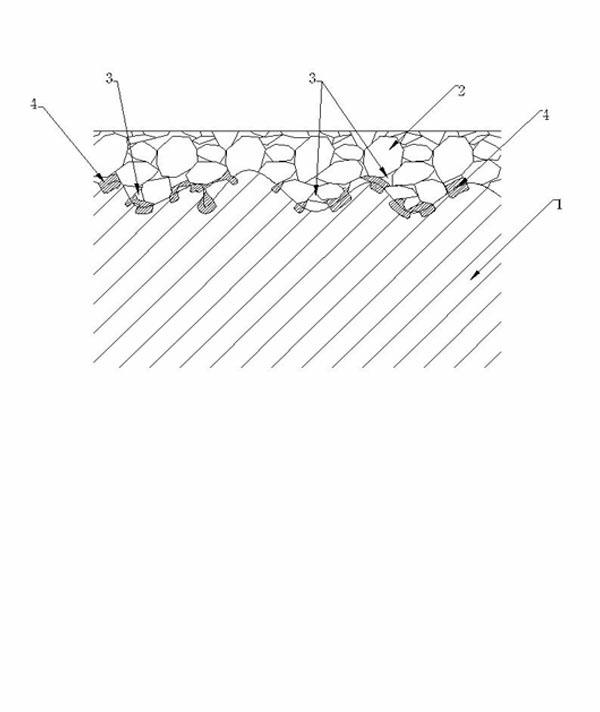

[0032] The first non-stick stainless iron pan is manufactured according to the following steps:

[0033] (1) Select high-quality low-carbon structural steel plates, cut the plates, stretch them, remove oil and wash them, perform surface treatment, decontaminate and dewax, and dry them;

[0034] (2) Roughen the surface to be processed by sand blowing to make the surface roughness reach Ra1 to Ra6;

[0035] (3) Use the high-speed low-temperature spraying method (the speed of the particles during spraying is 150m / s) to spray the iron-chromium carbide metal material particles with a particle size of 250 meshes on the working surface to form an easy-to-clean and non-stick layer, which is easy to clean and not sticky. The porosity of the micropores in the sticky layer is 1-3%;

[0036] (4) Polish the easy-clean non-stick layer. After polishing, the thickness of the easy-clean non-stick layer ranges from 0.005 to 0.05mm;

[0037] (5) Cleaning and drying;

[0038] (6) Nitriding tre...

Embodiment 2

[0049] The second non-stick stainless iron pan is manufactured according to the following steps:

[0050] (1) Select 403 stainless steel plate, cut the plate, stretch, degrease and clean, surface treatment, decontamination and wax removal, and dry;

[0051] (2) Roughen the surface to be processed by sand blowing to make the surface roughness reach Ra1 to Ra6;

[0052] (3) Use supersonic flame spraying (HVAF or HVOF) method (the speed of particles during spraying is 160m / s) to spray the nickel-chromium chromium carbide metal material particles with a particle size of 500 mesh on the working surface to form an easy-to-clean and non-toxic layer. The porosity of the micropores in the sticky layer and the easy-to-clean non-stick layer is 1 to 3%;

[0053] (4) Polish the easy-clean non-stick layer. After polishing, the thickness of the easy-clean non-stick layer ranges from 0.005 to 0.05mm;

[0054] (5) Cleaning and drying;

Embodiment 3

[0066] The third kind of non-stick stainless iron pan is manufactured according to the following steps:

[0067] (1) Select 440A stainless steel plate, cut the plate, stretch, degrease and clean, surface treatment, decontamination and wax removal, and dry;

[0068] (2) Roughen the surface to be processed by sand blowing to make the surface roughness reach Ra1 to Ra6;

[0069] (3) Use supersonic flame spraying (HVAF or HVOF) method (the speed of the particles during spraying is 160m / s) to spray the cobalt-chromium carbide metal material particles with a particle size of 400 mesh on the working surface to form an easy-to-clean and non-toxic layer. The porosity of the micropores in the sticky layer and the easy-to-clean non-stick layer is 1 to 3%;

[0070] (4) Polish the easy-clean non-stick layer. After polishing, the thickness of the easy-clean non-stick layer ranges from 0.005 to 0.05mm;

[0071] [ (5) Cleaning and drying;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com