Pulse combustion-driven hot fine water mist generation method and device

A technology of pulsating combustion and fine water mist, applied in spraying devices, liquid spraying devices, etc., can solve problems such as fog machines not working properly, achieve good fire extinguishing effect, high spraying speed, and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

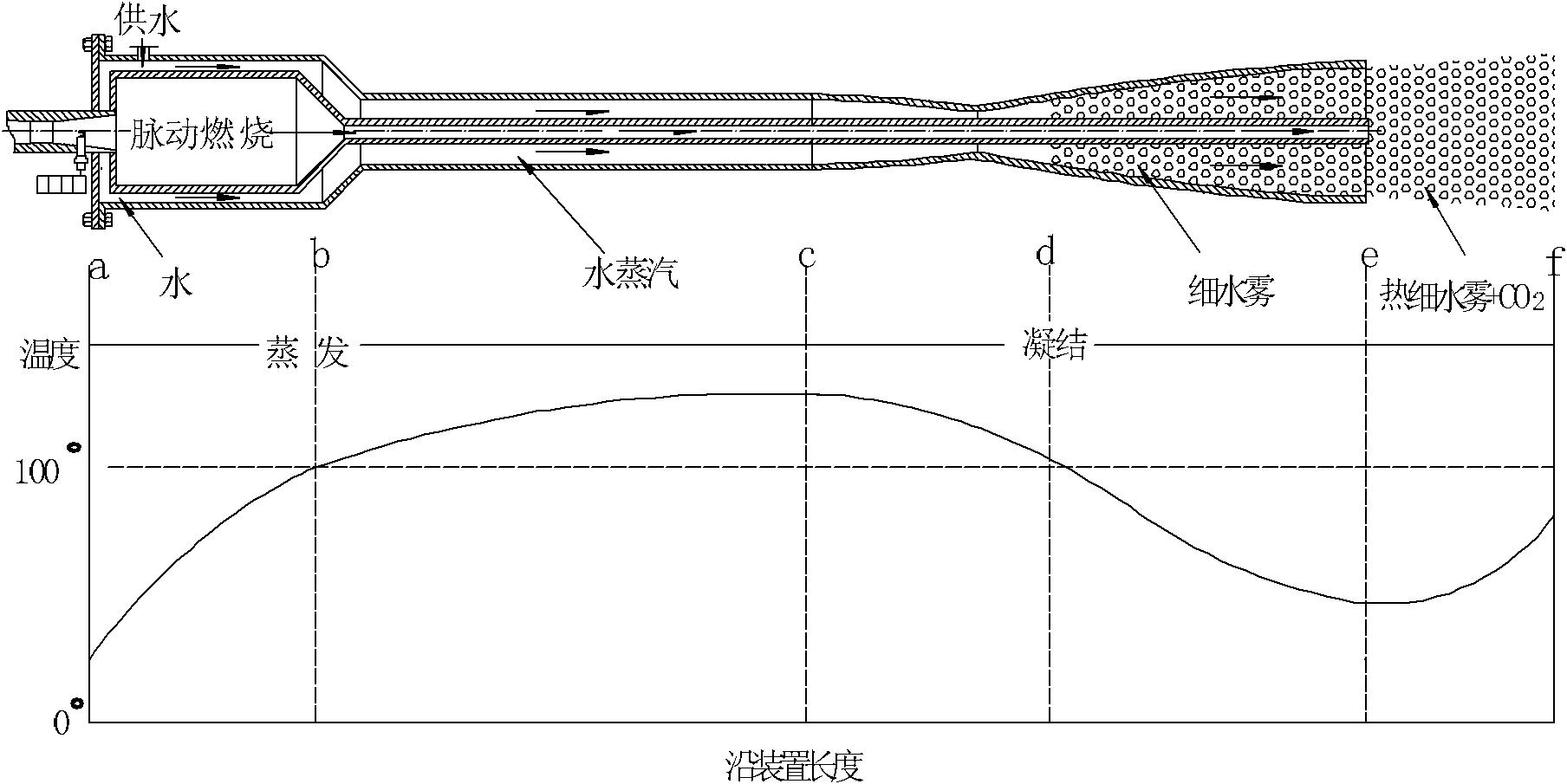

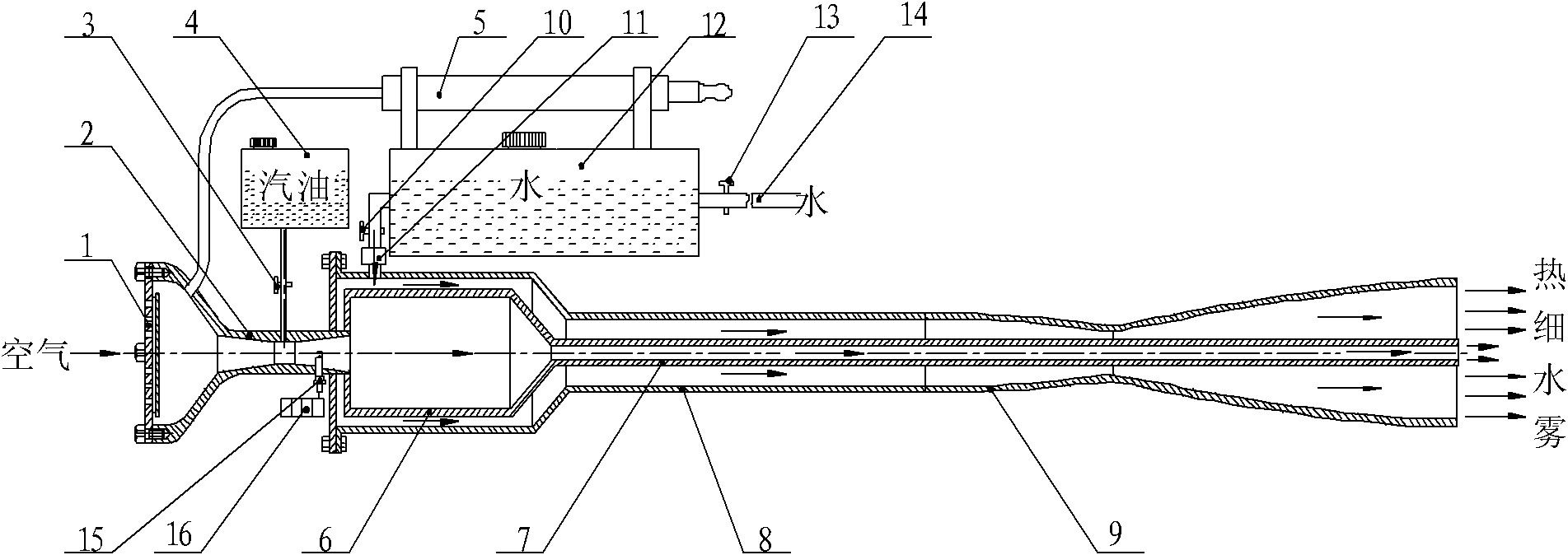

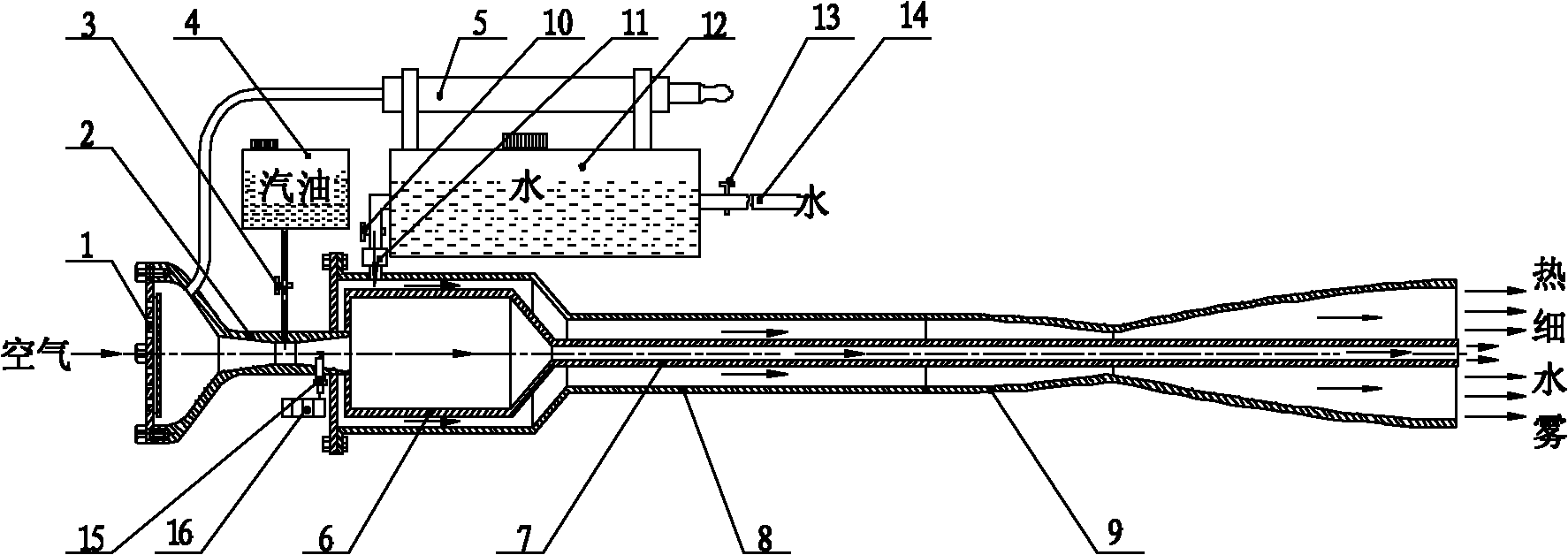

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 2As shown, a thermal mist generating device driven by pulsating combustion is composed of three parts, namely pulsating burner, jacket and water supply system. The pulsation burner adopts the Helmholtz acoustic resonator type, and the fuel is gasoline, mainly composed of an inlet check valve 1, a carburetor passage 2, a throttle 3, a fuel tank 4, an ignition manual air pump 5, a combustion chamber 6, and a tailpipe 7 , a spark plug 15 and an igniter 16; the jacket is an annular channel for the flow of water vapor formed outside the pulsation burner combustion chamber and the tailpipe, and is composed of a straight pipe jacket section 8 and a Laval jacket nozzle 9; the water supply system consists of a water flow The regulating valve 10, the pressure one-way valve 11, the water storage tank 12, the external water supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com