Laser machining method and device applicable for complicated curved surface

A laser processing method and complex curved surface technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of difficult disassembly and installation of the processing head, low applicability, etc., to expand the scope of application, low processing efficiency, and consumption can have a big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

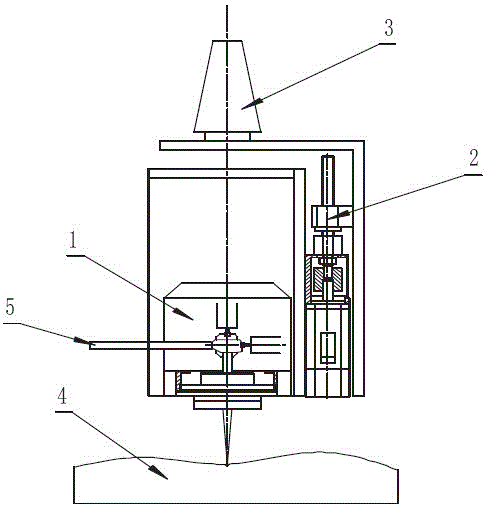

[0037] Typical implementations of the present invention will be described in detail below with the help of drawings and examples.

[0038] As a method for precisely scanning and processing the surface of parts with complex curved surfaces by using focused laser beams, the invention is applicable to various laser wavelengths, powers, scanning speeds and other technological parameters.

[0039] When implementing the method of the present invention, first analyze the processing requirements, and select a two-axis scanning laser galvanometer that can realize the processing requirements. It is driven by a motor to deflect two X and Y laser plane mirrors to complete the scanning motion, and the scanning focus lens Focus on material processing. Generally, after the size of the laser plane mirror in the laser galvanometer, the motor, the aperture and focal length of the scanning focus lens are determined, parameters such as the scanning range of the galvanometer, the working focal len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com