Cutting method for adjusting crystal orientation excursion by rotating single crystal rod

A cutting method and technology for single crystal rods, which are used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of large size deviation of silicon wafer mechanical indicators, affecting the quality of slices and yield, and improve mechanical indicators. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below.

[0009] 1. Derivation of calculation formula:

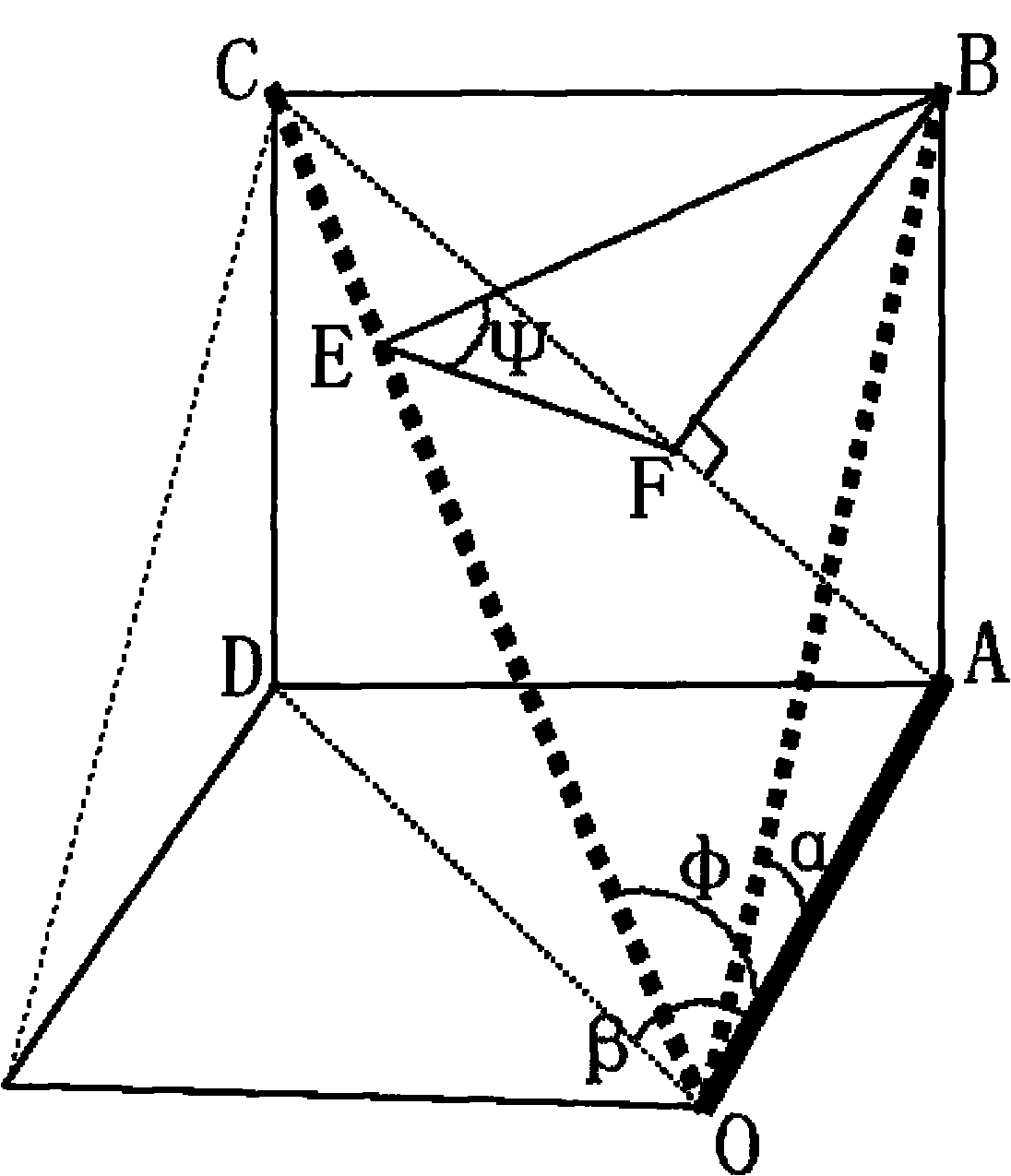

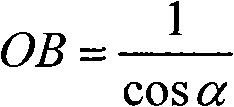

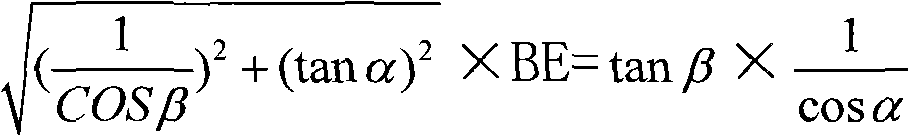

[0010] refer to figure 1 , let the single crystal rod length Radial longitudinal deflection angle ∠AOB=α, radial lateral deflection angle ∠AOD=β, radial plane adjustment angle ∠AOC=φ, silicon standard surface rotation angle ∠BEF=ψ. Among them, AOD is the initial cutting platform surface, AOC is the final cutting platform surface, BOC is the single crystal ingot standard surface, ABC is the blade cutting surface, is the cutting direction. The initial monocrystalline silicon radial direction is The adjusted radial direction is

[0011] Then, (1) AB=tanα AD=tanβ

[0012] but AC = BC 2 + AB 2 = ( tan β ) 2 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com