Thermal insulation material and preparation method thereof

A technology of thermal insulation materials and aggregates, applied in ceramic products, other household utensils, applications, etc., can solve the problems of high thermal conductivity, difficulty in adapting to industrial kiln working conditions, low compressive strength, etc., and achieve high mechanical index, closed mouth Less porosity and lower thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

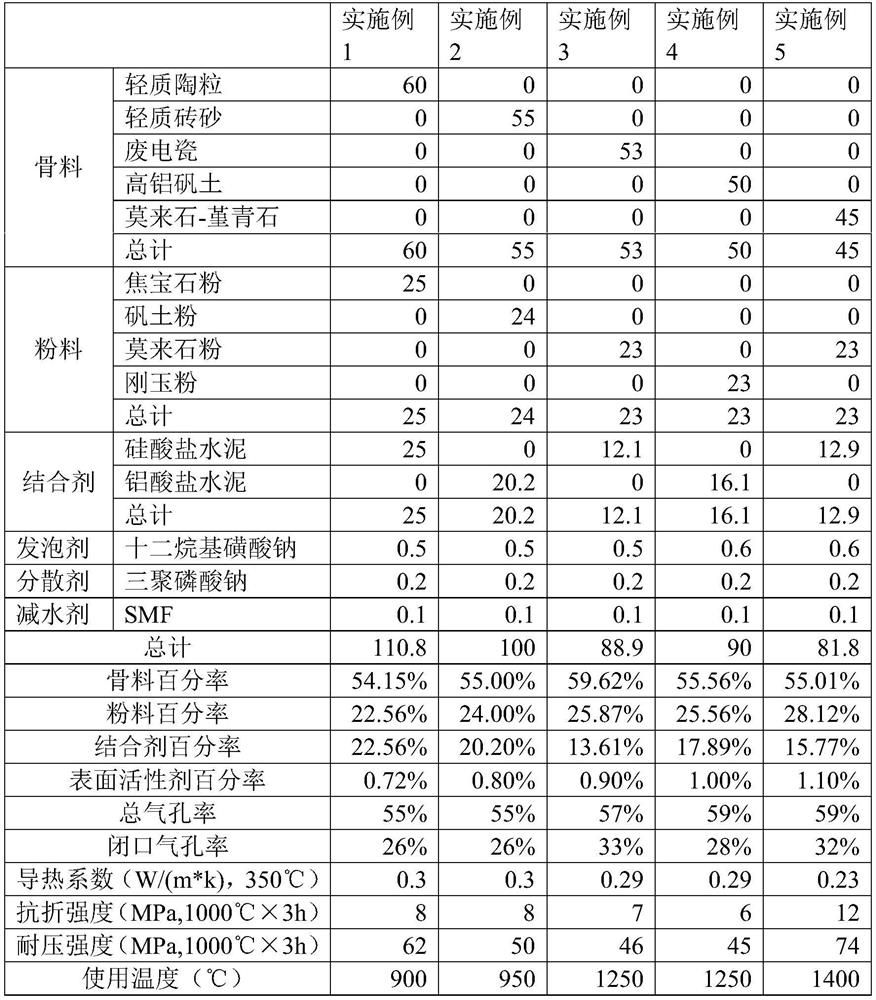

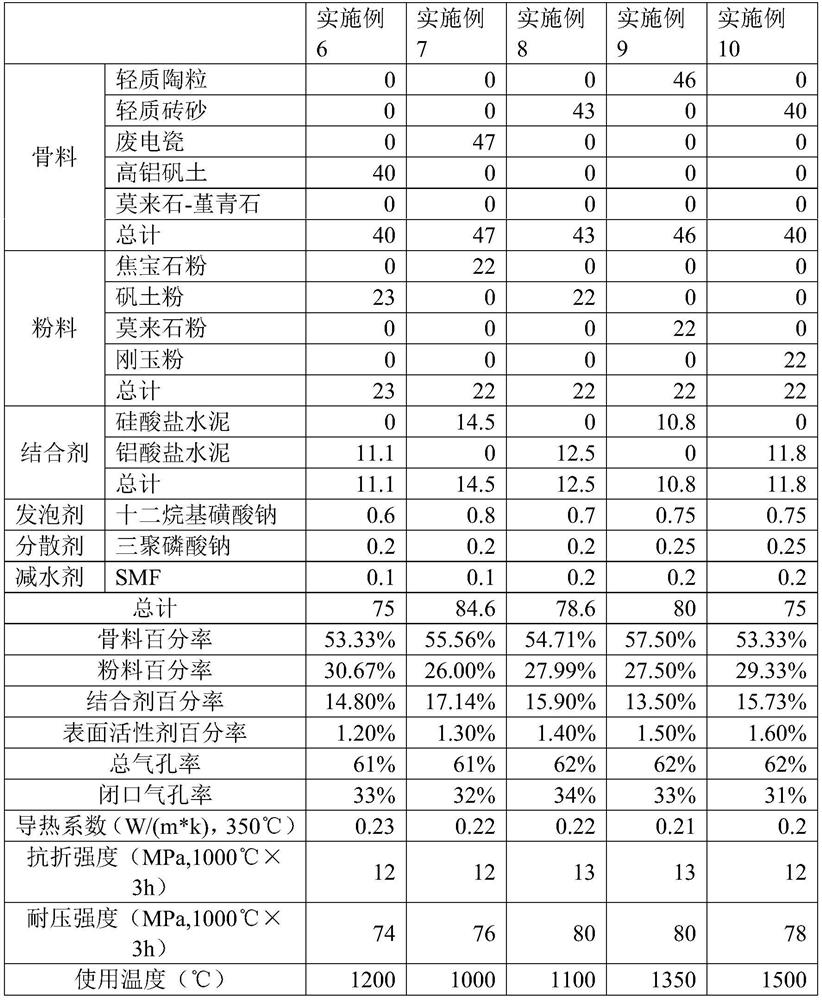

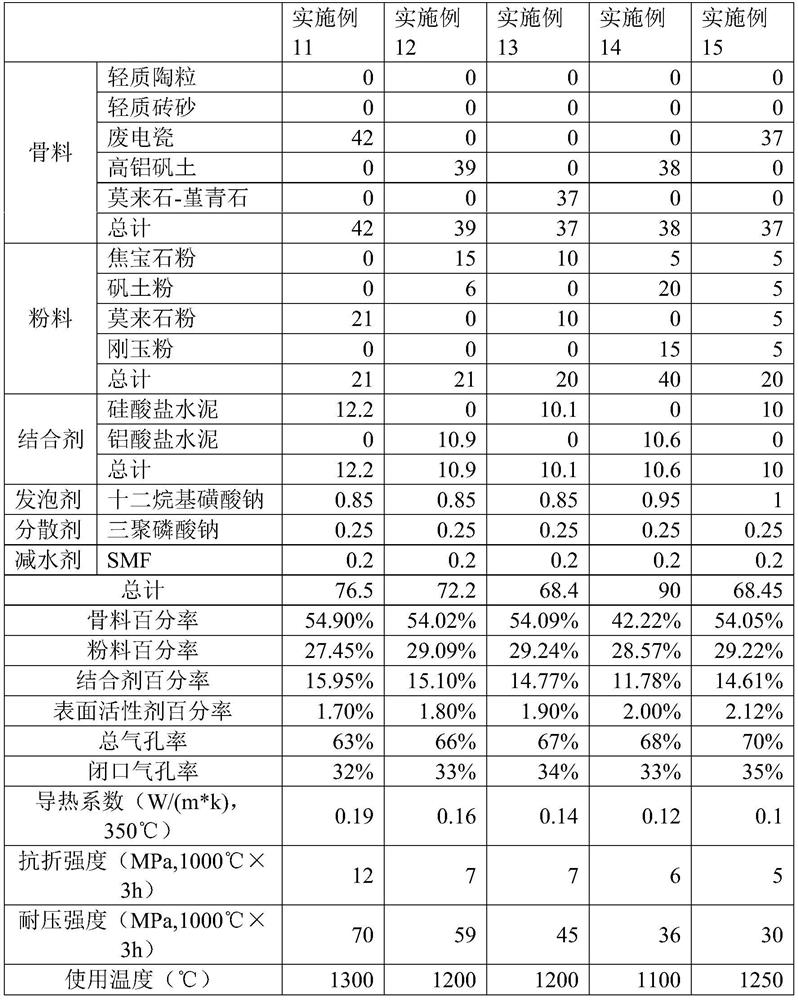

Examples

Embodiment 1

[0025] A thermal insulation material, comprising the following components: 60 parts by weight of aggregate, 25 parts by weight of powder, 25 parts by weight of a binder, 0.5 parts by weight of a foaming agent, 0.2 parts by weight of a dispersant, 0.1 parts by weight of Water reducing agent.

[0026] The aggregate is lightweight ceramsite, and the lightweight ceramsite is light shale ceramsite.

[0027] The powder is burnt gemstone powder.

[0028] The binder is Portland cement.

[0029] Foaming agents are anionic surfactants.

[0030] Further, the aggregate gradation is: 5-3mm, 3-1mm, below 1mm, wherein, the weight of the 5-3mm aggregate: the weight of the 3-1mm aggregate: the weight of the aggregate below 1mm=12: 10:15; the particle size of the powder is 180 mesh.

[0031] Further, the foaming agent is sodium dodecylsulfonate.

[0032] Further, the dispersant is sodium tripolyphosphate.

[0033] Further, the melamine water reducer is sulfonated melamine formaldehyde res...

Embodiment 2

[0038] A thermal insulation material, comprising the following components: 55 parts by weight of aggregate, 24 parts by weight of powder, 20.2 parts by weight of a binder, 0.5 parts by weight of a foaming agent, 0.2 parts by weight of a dispersant, 0.1 parts by weight of Water reducing agent.

[0039] The aggregate is light brick sand, and the light brick sand is Al 2 o 3 The content is 45%, the body density is 0.5g / cm 3 of waste bricks and brick sand.

[0040] The powder is alumina powder.

[0041] The binder is aluminate cement.

[0042] Foaming agents are anionic surfactants.

[0043] Further, the aggregate gradation is: 5-3mm, 3-1mm, below 1mm, wherein, the weight of the 5-3mm aggregate: the weight of the 3-1mm aggregate: the weight of the aggregate below 1mm=15: 20:25; the particle size of the powder is 200 mesh.

[0044] Further, the foaming agent is sodium dodecylsulfonate.

[0045] Further, the dispersant is sodium tripolyphosphate.

[0046] Further, the melam...

Embodiment 3

[0051] A thermal insulation material, comprising the following components: 53 parts by weight of aggregate, 23 parts by weight of powder, 12.1 parts by weight of a binder, 0.5 parts by weight of a foaming agent, 0.2 parts by weight of a dispersant, 0.1 parts by weight of Water reducing agent.

[0052] The aggregate is waste electrical porcelain.

[0053]The powder is mullite powder.

[0054] The binder is Portland cement.

[0055] Foaming agents are anionic surfactants.

[0056] Further, the aggregate gradation is: 5-3mm, 3-1mm, below 1mm, wherein, the weight of 5-3mm aggregate: the weight of 3-1mm aggregate: the weight of aggregate below 1mm=13: 15:20; the particle diameter of described powder is 200 orders.

[0057] Further, the foaming agent is sodium dodecylsulfonate.

[0058] Further, the dispersant is sodium tripolyphosphate.

[0059] Further, the melamine water reducer is sulfonated melamine formaldehyde resin (SMF).

[0060] The invention relates to a preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com