Mixed material and method for filling asphalt pavement after core drilling and sampling

A technology of asphalt pavement and core drilling, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as improper filling of potholes, achieve good waterproof effect, improve cohesion, and meet the requirements of structural bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

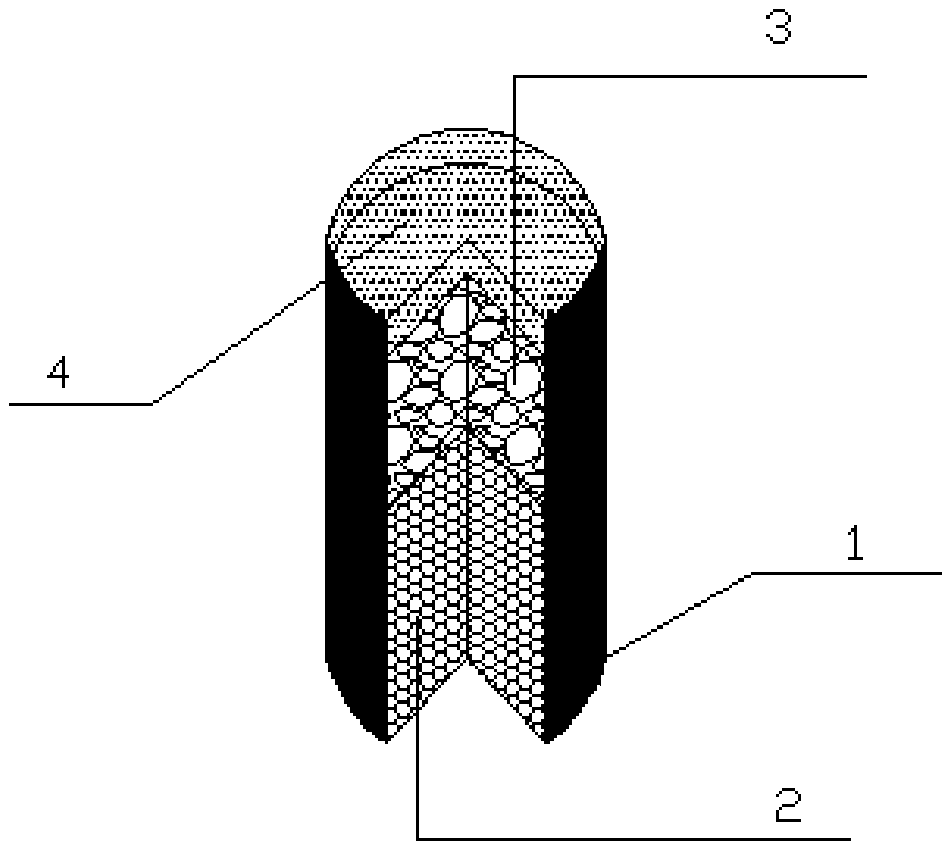

Image

Examples

Embodiment 1

[0049] 1. Weigh 90kg of MS-4 mineral material, 12kg of SBS modified emulsified asphalt, 3kg of expansion agent, 6kg of filler, and 1kg of water for mixing to make asphalt micro-surfacing.

[0050] 2. Weigh 100kg of emulsified asphalt, 20.2kg of water-based epoxy resin, 40.4kg of curing agent, 20.2kg of ordinary portland cement, 55.6kg of fast hardening sulfoaluminate cement, 74.74kg of quartz sand, 4kg of water reducing agent, 2kg of slow Coagulant, 1.2kg early-strength agent, 1.4kg defoamer for mixing, configured into cold-patch asphalt mortar.

[0051] 3. Weigh 250kg of dry powder, the river sand gradation is discontinuous gradation, and the particle size is 1.18mm;

[0052] 4. Clean up the potholes that need to be repaired, spray emulsified asphalt on the bottom of the pothole and its surroundings, and set up asphalt micro-surface, cold-patch asphalt mortar and dry powder layer on the bottom of the pothole, and adjust the thickness of each layer according to the thickness o...

Embodiment 2

[0054] 1. Weigh 180kg of MS-4 mineral material, 24kg of SBS modified emulsified asphalt, 6kg of expansion agent, 12kg of filler, and 1.8kg of water for mixing to make asphalt micro-surfacing.

[0055] 2. Weigh 200kg of emulsified asphalt, 42kg of water-based epoxy resin, 80kg of curing agent, 31.6kg of ordinary Portland cement, 94.6kg of fast-hardening sulfoaluminate cement, 147kg of quartz sand, 7.4kg of water-reducing agent, and 3kg of retarder , 1.6kg early-strength agent, 2.6kg defoamer for mixing, configured as cold-patch asphalt mortar.

[0056] 3. Weigh 250kg of dry powder, the river sand gradation is discontinuous gradation, and the particle size is 1.18mm;

[0057] 4. Clean up the potholes that need to be repaired, spray emulsified asphalt on the bottom of the pothole and its surroundings, and set up asphalt micro-surface, cold-patch asphalt mortar and dry powder layer on the bottom of the pothole, and adjust the thickness of each layer according to the thickness of t...

Embodiment 3

[0059] 1. Weigh 45kg of MS-4 mineral material, 6kg of SBS modified emulsified asphalt, 1.5kg of expansion agent, 3kg of filler, and 0.4kg of water for mixing to make asphalt micro-surfacing.

[0060] 2. Weigh 50kg of emulsified asphalt, 11.1kg of water-based epoxy resin, 19.9kg of curing agent, 5.5kg of ordinary portland cement, 19.3kg of rapid hardening sulfoaluminate cement, 36.4kg of quartz sand, 1.6kg of water reducing agent, 0.45 kg retarder, 0.2kg early-strength agent, 0.6kg defoamer for mixing, configured as cold patch asphalt mortar.

[0061] 3. Weigh 250kg of dry powder, the river sand gradation is discontinuous gradation, and the particle size is 1.18mm;

[0062] 4. Clean up the potholes that need to be repaired, spray emulsified asphalt on the bottom of the pothole and its surroundings, and set up asphalt micro-surface, cold-patch asphalt mortar and dry powder layer on the bottom of the pothole, and adjust the thickness of each layer according to the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com