Metal organic compound collosol/organic silicone compound icing-proof coating and preparation method thereof

A technology of organic compounds and silicones, applied in coatings and other directions, can solve the problems of limited anti-icing durability, loss of anti-icing ability, limited deicing effect, etc., and achieve the effect of improving anti-icing and good spectral heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

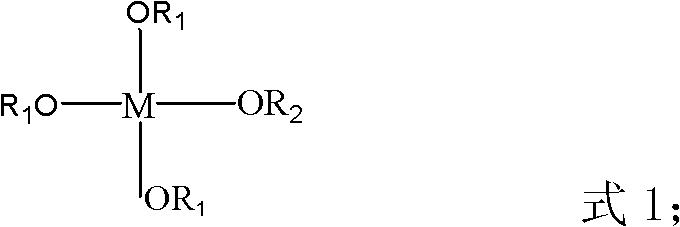

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of metal organic compound sol / organosilicon composite anti-icing coating, it comprises the steps:

[0033] 1) Metal alkoxide is obtained by electrochemical method:

[0034] (1) Preparation of electrolyte solution and electrodes:

[0035] First, use No. 4 molecular sieve to remove water from isopropanol, and then prepare 180 mL of 0.0015 mol / L (Bu 4 The isopropanol solution of N) Br is used as electrolytic solution; Get purity again and be 99wt% metal aluminum flake, it is cut into wide 3cm, 2 rectangular sheets of long 6cm, then use 04 # Type metallographic sandpaper to polish the two sheets until their surface is smooth, then immerse the two sheets in 40g of acetone, soak for 10h to activate the surface of the metal sheet, and use them as electrolysis anode and electrolysis cathode respectively;

[0036] (2) Preparation of metal alkoxide:

[0037] The electrolytic anode and electrolytic cathode obtained in step (1) were respectively connected ...

Embodiment 2

[0047] The preparation method of metal organic compound sol / organosilicon composite anti-icing coating, it comprises the steps:

[0048] 1) Metal alkoxide is obtained by electrochemical method:

[0049] (1) Preparation of electrolyte solution and electrodes:

[0050] First, use No. 4 molecular sieve to remove water from isopropanol, and then prepare 150 mL of 0.002 mol / L (Bu 4 The isopropanol solution of N) Br is used as electrolytic solution; Get purity again and be 99wt% metal aluminum sheet, it is cut into wide 2em, 2 rectangular sheets of long 6em, then use 04 # Type metallographic sandpaper to polish the two sheets until their surface is smooth, then immerse the two sheets in 45g of acetone, soak for 9h to activate the surface of the metal sheet, and use them as electrolysis anode and electrolysis cathode respectively;

[0051] (2) Preparation of metal alkoxide:

[0052] The electrolytic anode and electrolytic cathode obtained in step (1) were respectively connected to...

Embodiment 3

[0059] The preparation method of metal organic compound sol / organosilicon composite anti-icing coating, it comprises the steps:

[0060] 1) Metal alkoxide is obtained by electrochemical method:

[0061] (1) Preparation of electrolyte solution and electrodes:

[0062] First remove water from isopropanol with No. 4 molecular sieve, and then prepare 200mL of 0.0035mol / L (Bu 4 The isopropanol solution of N) Br is used as electrolytic solution; Get purity again and be 99wt% metal aluminum sheet, it is cut into wide 2.5cm, 2 rectangular sheets of long 7cm, then use 04 # Type metallographic sandpaper to polish the two sheets until their surface is smooth, then immerse the two sheets in 55g of acetone, soak for 11h to activate the surface of the metal sheet, and use them as electrolysis anode and electrolysis cathode respectively;

[0063] (2) Preparation of metal alkoxide:

[0064] The electrolytic anode and electrolytic cathode obtained in step (1) were respectively connected to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com