Thrust auxiliary reamer bit

A technology for reaming drill bits and drill bits, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of unguaranteed aperture quality and small application range of drill bits, and achieve the effects of simple structure, safe and reliable performance, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

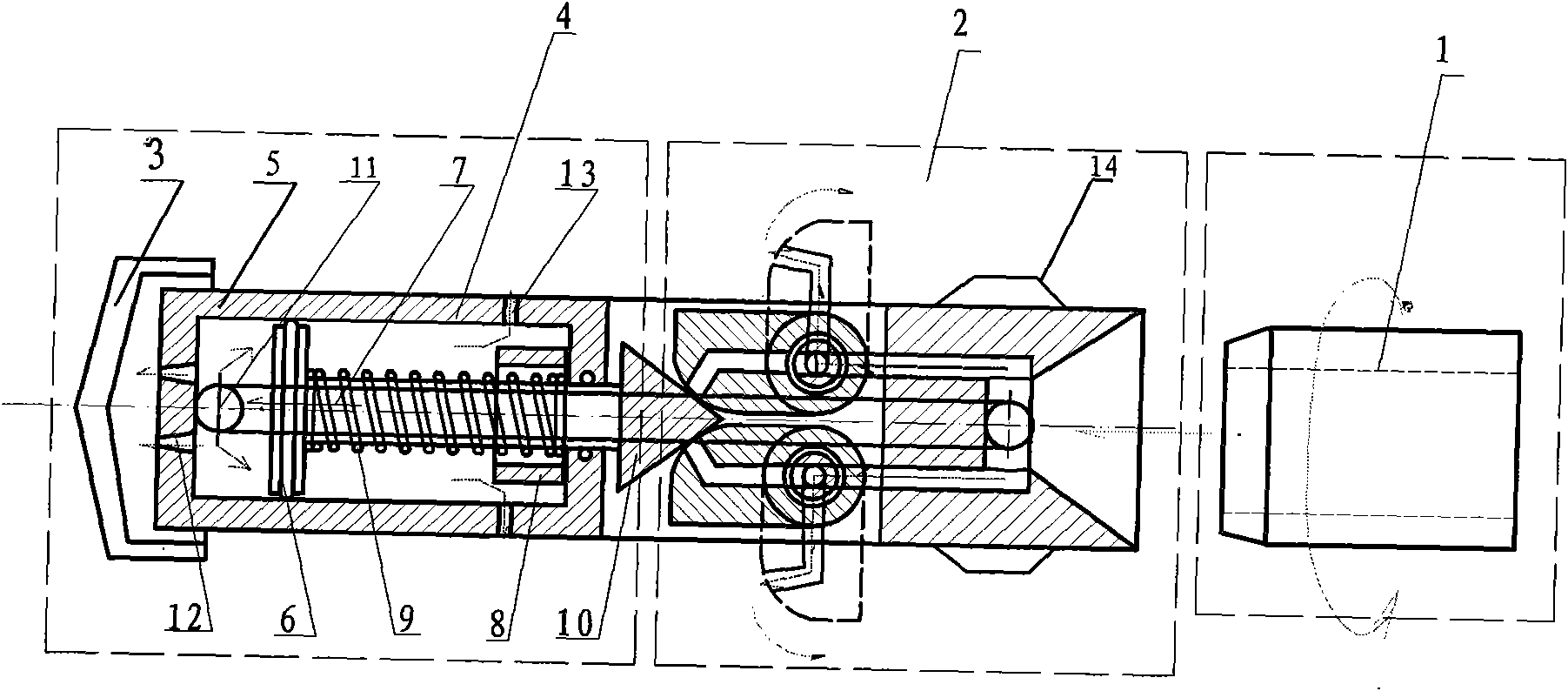

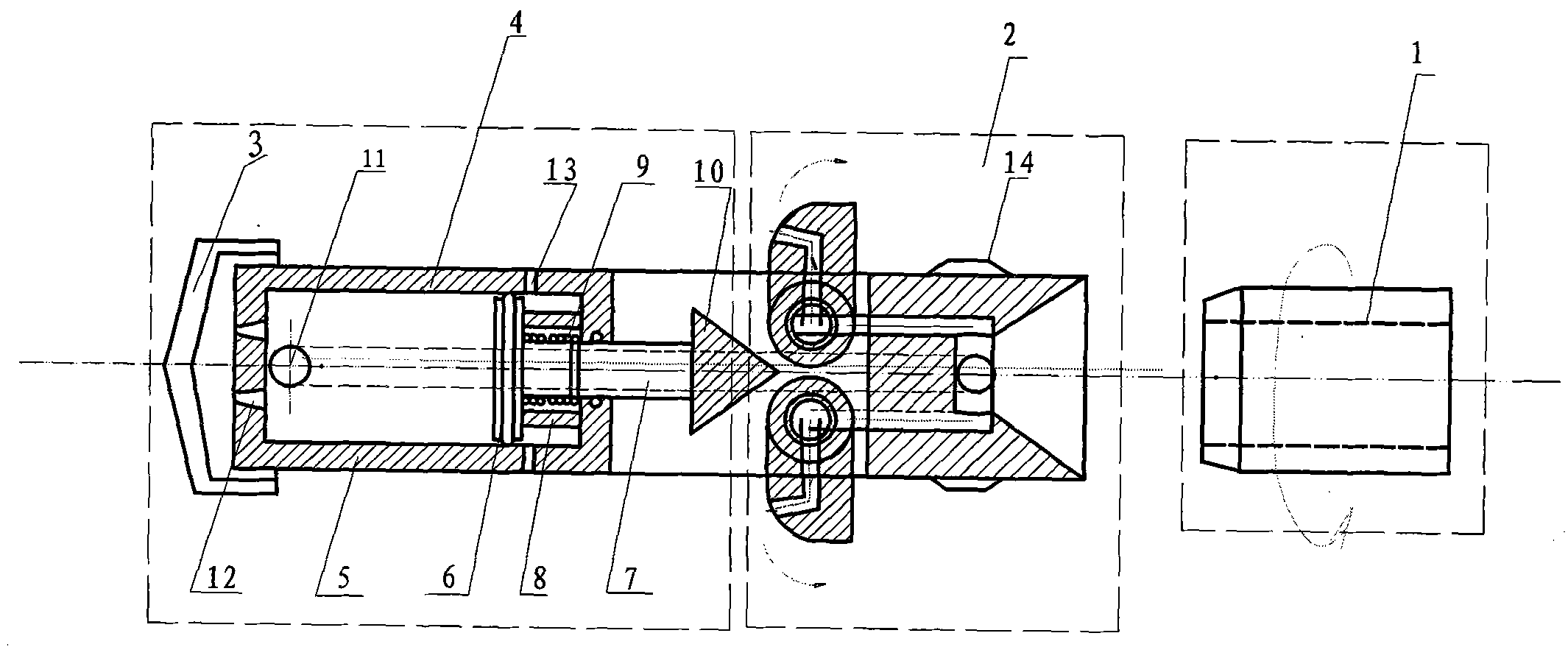

[0014] Concrete structure of the present invention sees attached figure 1 or attach figure 2 . The force-assisted reaming drill bit includes a drill rod 1 , a multi-blade reamer 2 and a drill bit 3 , and the three are connected in sequence. It is characterized in that a force-pushing device 4 is added between the reamer 2 and the drill bit 3 . Driven by the drill bit 1 and the forced pushing device 4, the present invention can better complete the drilling function and the hole reaming function.

[0015] Because the hole reamer 2 of the present invention and the forced pushing device 4 are of an integrated structure, that is, the two are connected in the form of a cylinder liner, the length of the drill bit 3 is increased, and there is a righting and guiding function, which can ensure the required reaming. Aperture size quality requirements.

[0016] The specific motion mode of the present invention is accomplished jointly by drilling rod 1, multi-wing reamer 2, forced thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com