Comprehensive heating system by using hot water based on fire pit

A comprehensive system and combustion pool technology, applied in heating systems, household heating, applications, etc., to achieve the effect of simple structure, low cost and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

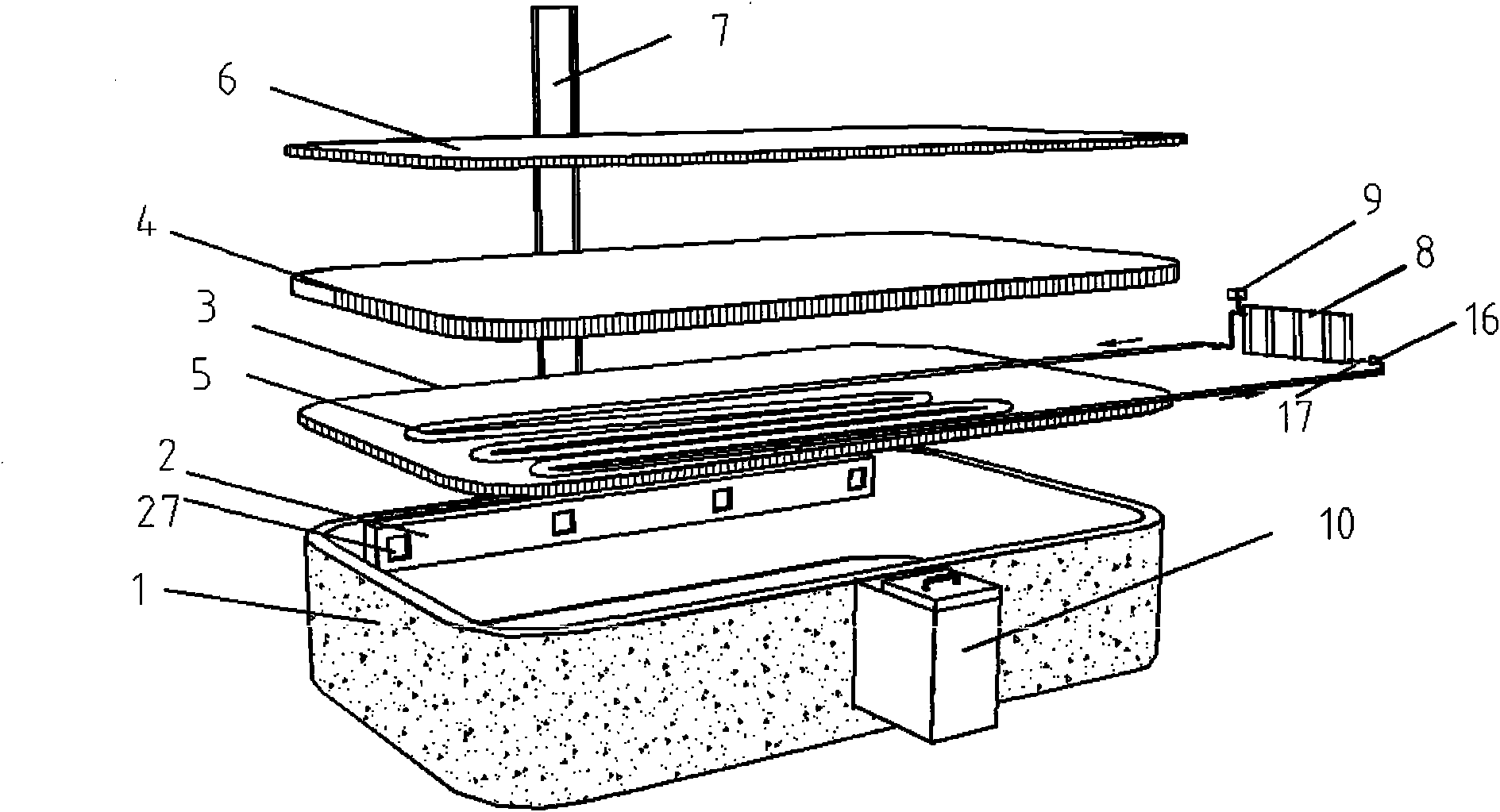

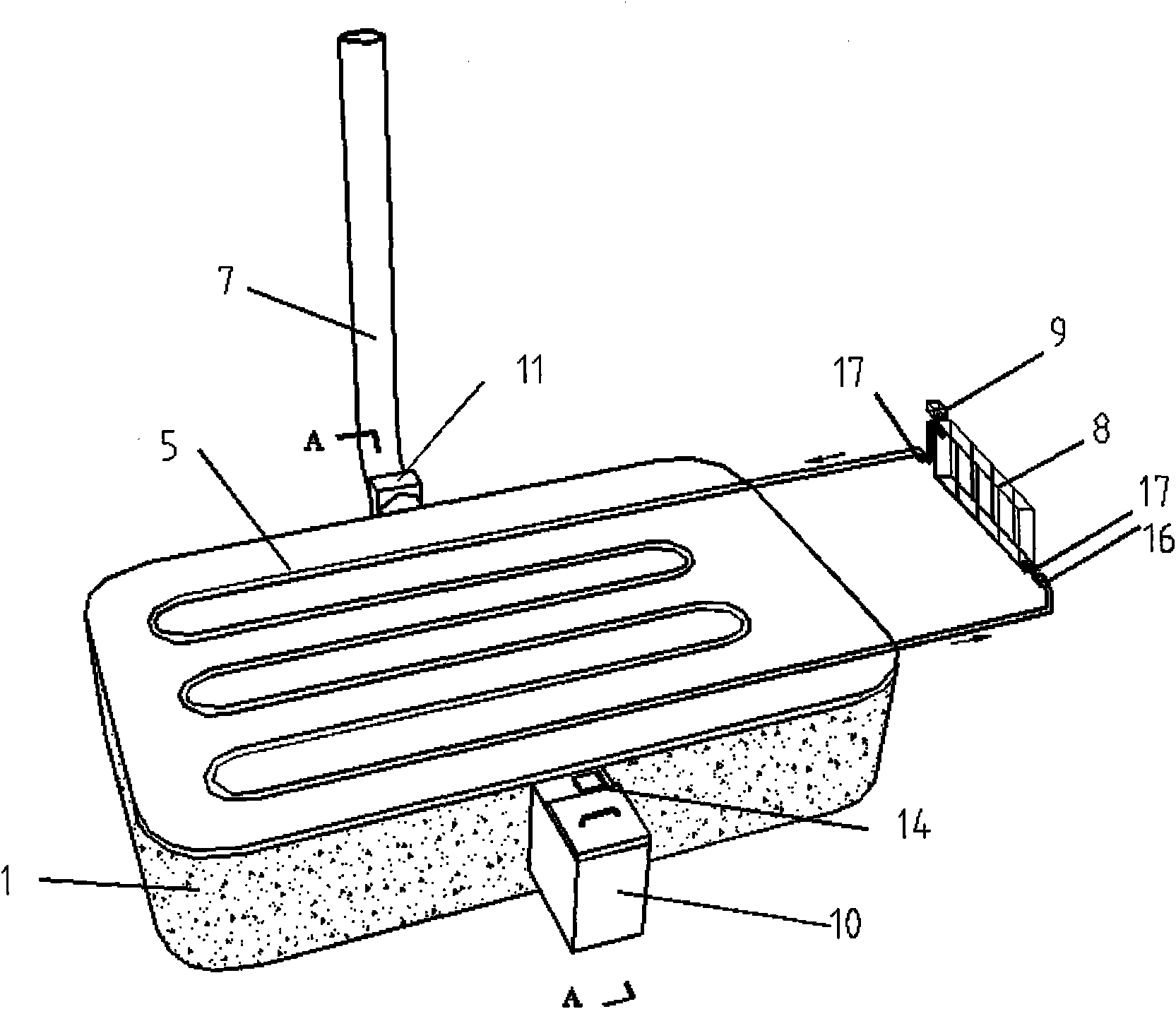

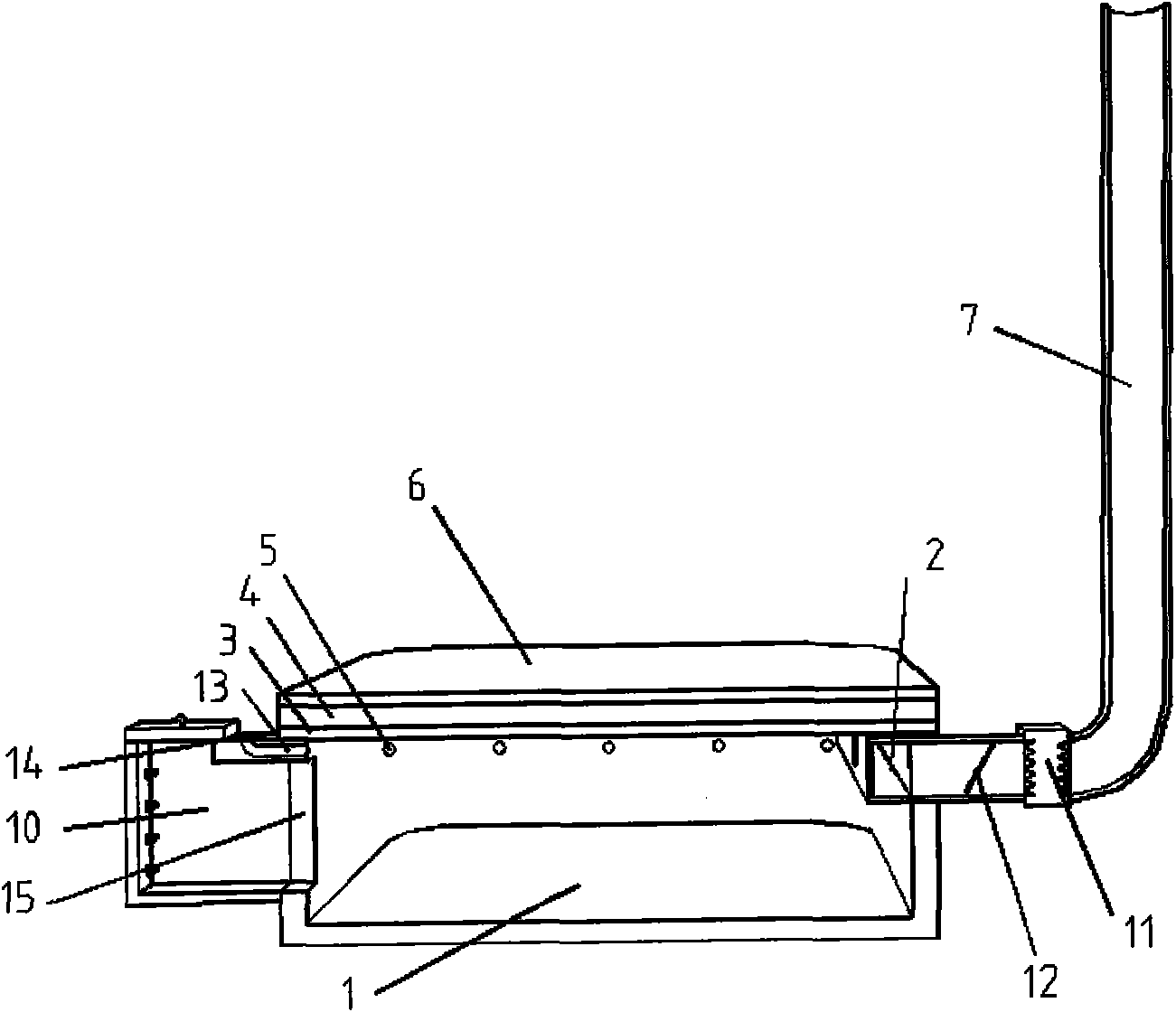

[0014] Specific implementation plan one: if Figure 1~2 As shown, the comprehensive heating system based on the use of hot water in the combustion pool is mainly composed of the main body of the combustion pool 1, the horizontal flue 2, the hot water coil 5, the vertical chimney 7, the radiator 8, the expansion tank 9, the filling port 10, and the flue gas filter device 11, smoke control valve 12 and other components. The main body of the fuel pool 1 is a rounded rectangle with a depth of 1.7 meters. The filling port 10 is located at the center of the front of the main body 1 of the fuel pool. Straight climbing ladder 26 is convenient for filling and overhaul. The entrance 15 of the combustion pool is sealed by a prefabricated concrete slab or a brick block, and can be opened and closed freely.

specific Embodiment approach 2

[0015] Specific implementation plan two: if Figure 1~4 As shown, the hot water coil 5 can be fixed under the cover plate of the combustion pool, between the cover plate 3 and the ground layer 6, and the hot water coil 5 is an iron pipe, which is connected with the radiator 8 outside the combustion pool to form a closed circuit, the flow in the hot water coil 5 is controlled by the regulating valve 17 and the water pump 16. The cover plate 3 is prefabricated with reinforced concrete, the ground layer 6 is a cement leveling layer, and the loess layer 4 can prevent the leakage of smoke.

specific Embodiment approach 3

[0016] Specific implementation plan three: if figure 2 As shown in ~ 5, the flue system is composed of a horizontal flue 2, several flue openings 27, a flue gas filter 11, and a vertical chimney 7. The horizontal flue 2 is located at the top of the inner wall at the back of the combustion pool main body 1 , below the combustion pool cover plate 3 , and consists of four symmetrical flue openings 27 . The flue gas is collected into the horizontal flue 2, purified by the flue gas filter 11, and discharged from the chimney 7. A flue gas control valve 12 is also provided at the bottom of the chimney, and the smoke exhaust volume is controlled by changing the angle of the flue gas control valve 12 .

[0017] Specific implementation plan four: as figure 1 As shown in ~5, after the fuel stalks, wood chips, corncobs, etc. in the main body of the combustion pool 1 are smoldering, the medium water in the hot water coil 5 is heated, and after the hot water transfers the heat through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com