Device and method for detecting alignment parameter of photoetching machine

The technology of a detection device and detection method is applied in the direction of the photoplate making process of originals, optics, and patterned surfaces for photomechanical processing, and can solve the problems of complex detection methods and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The device for detecting the alignment parameters of the photolithography machine and the detection method thereof according to the present invention will be described in detail below in conjunction with the accompanying drawings. Before describing the detection device for the alignment parameters of the lithography machine of the present invention, the structure of the wafer used as the basis for producing integrated circuit chips in this embodiment will be described first.

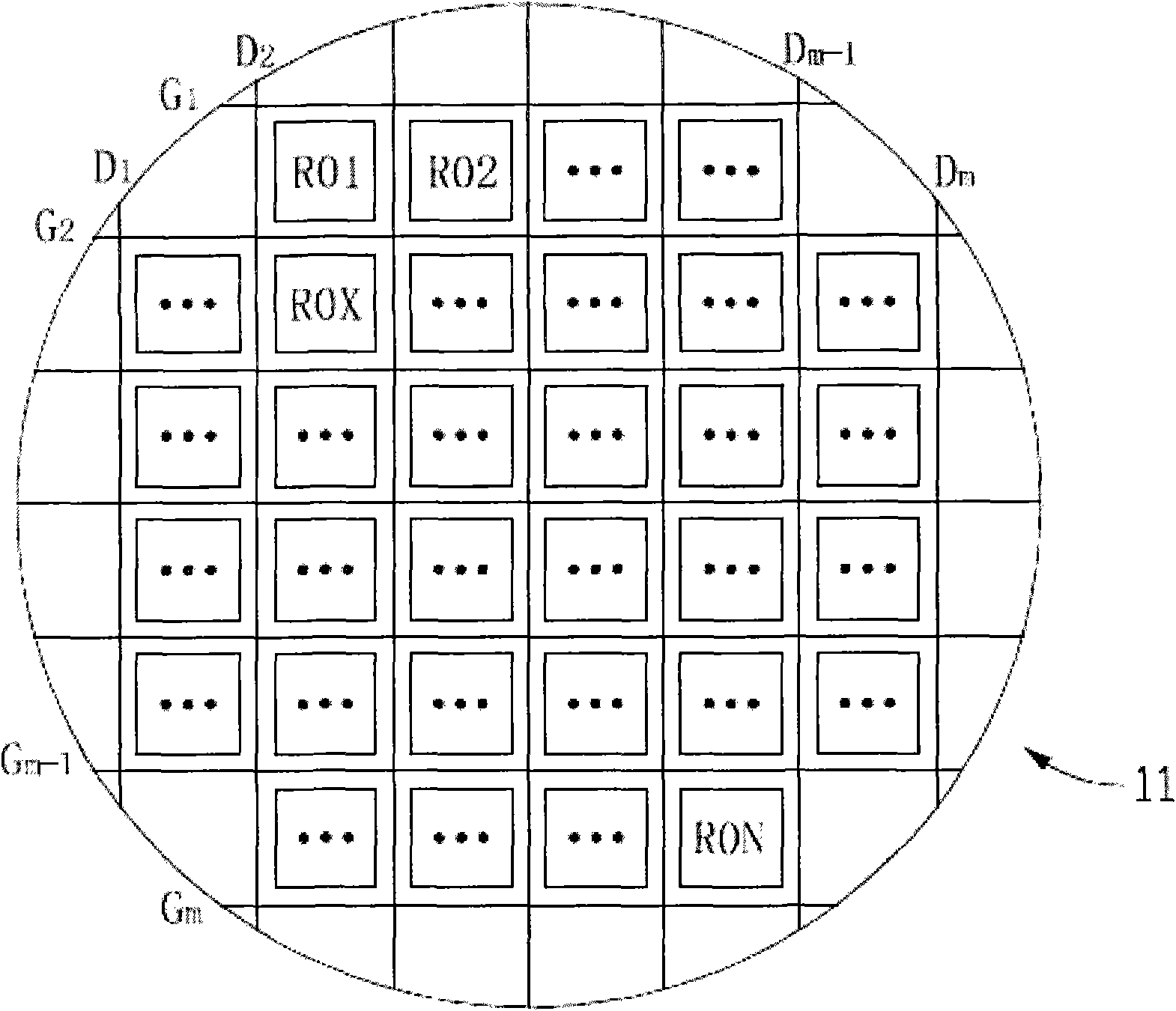

[0033] see figure 1 , which is a schematic diagram of the structure of the wafer of the present invention. The wafer 11 includes m first dicing lines G1, G2, . Tracks D1 , D2 , . . . , Dm-1 , Dm and a plurality of exposure regions R01 , R02 , . . . , R0X, . The multiple first cutting lines G1, G2, . . . , Gm-1, Gm are perpendicular to the multiple second cutting lines D1, D2, ..., Dm-1, Dm. Every two adjacent first scribe lines Gm and every two adjacent second scribe lines Dm correspond to defi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com