Method for reducing surface light reflectivity of silicon chip

A technology of light reflectivity and silicon wafer surface, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of complex process and high cost, achieve low light reflectivity, low cost, and benefit The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

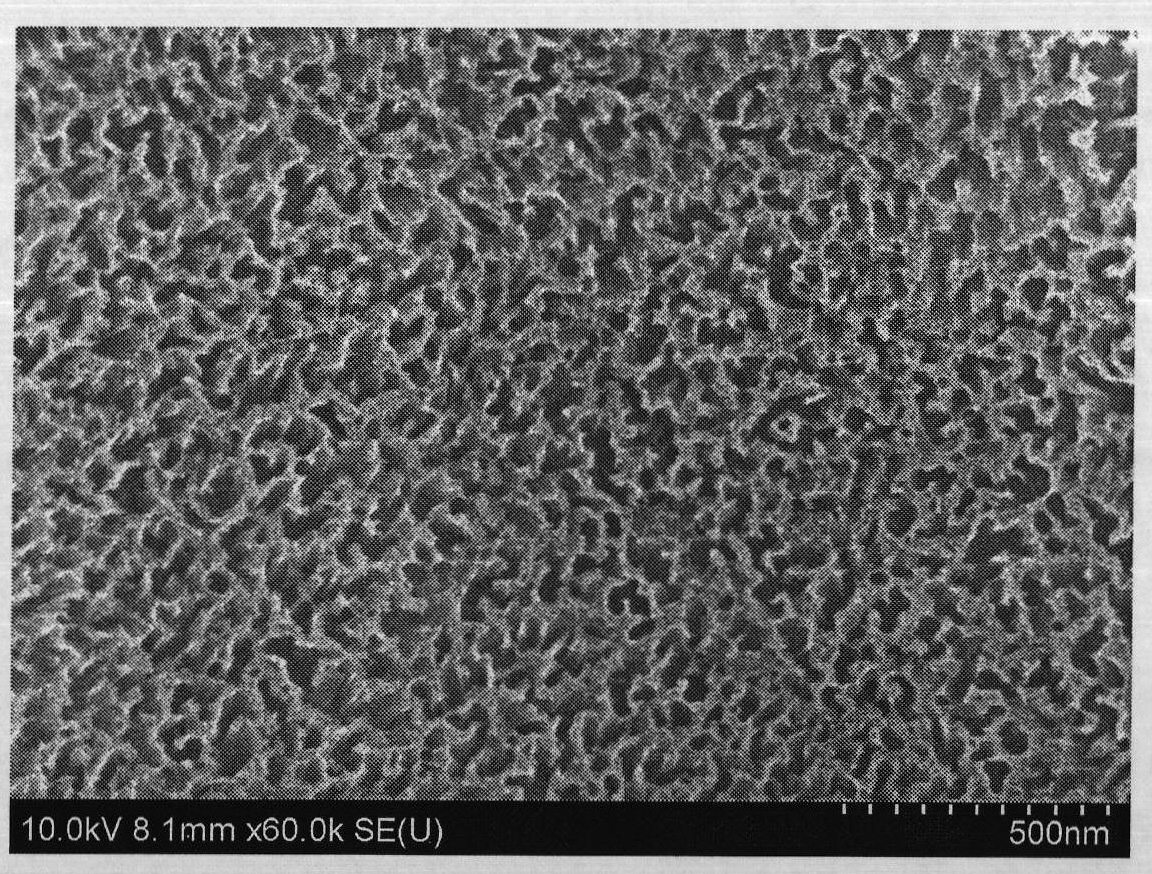

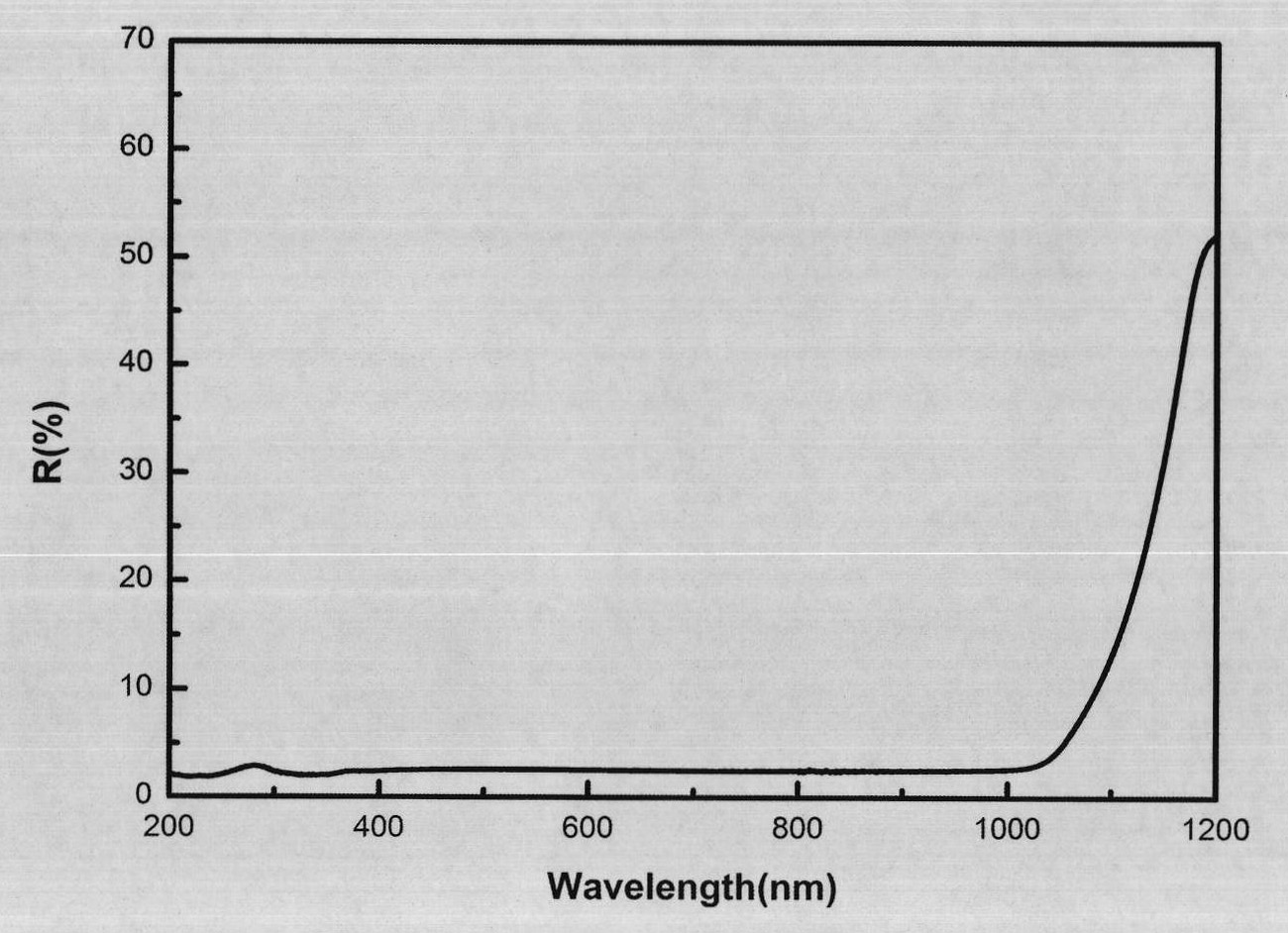

[0051] Clean the p-type Si(100) with a size of 125mm×125mm (resistivity 1-3Ωcm) by traditional techniques, and immerse the silicon wafer in a mixed solution containing 5.1mol / L hydrofluoric acid and 0.03mol / L silver nitrate , etch for 3 min. Then the silicon wafer was taken out, ultrasonically cleaned with nitric acid (concentration 68%) to remove the metal covered on the surface, then ultrasonically cleaned with deionized water, and then dried with high-purity nitrogen to obtain black silicon with low reflectivity. SEM of the light-trapping structure on the silicon surface after etching figure 1 As shown, a nanoporous structure is formed on the surface of the silicon wafer. The obtained reflectance is as figure 2 shown.

Embodiment 2

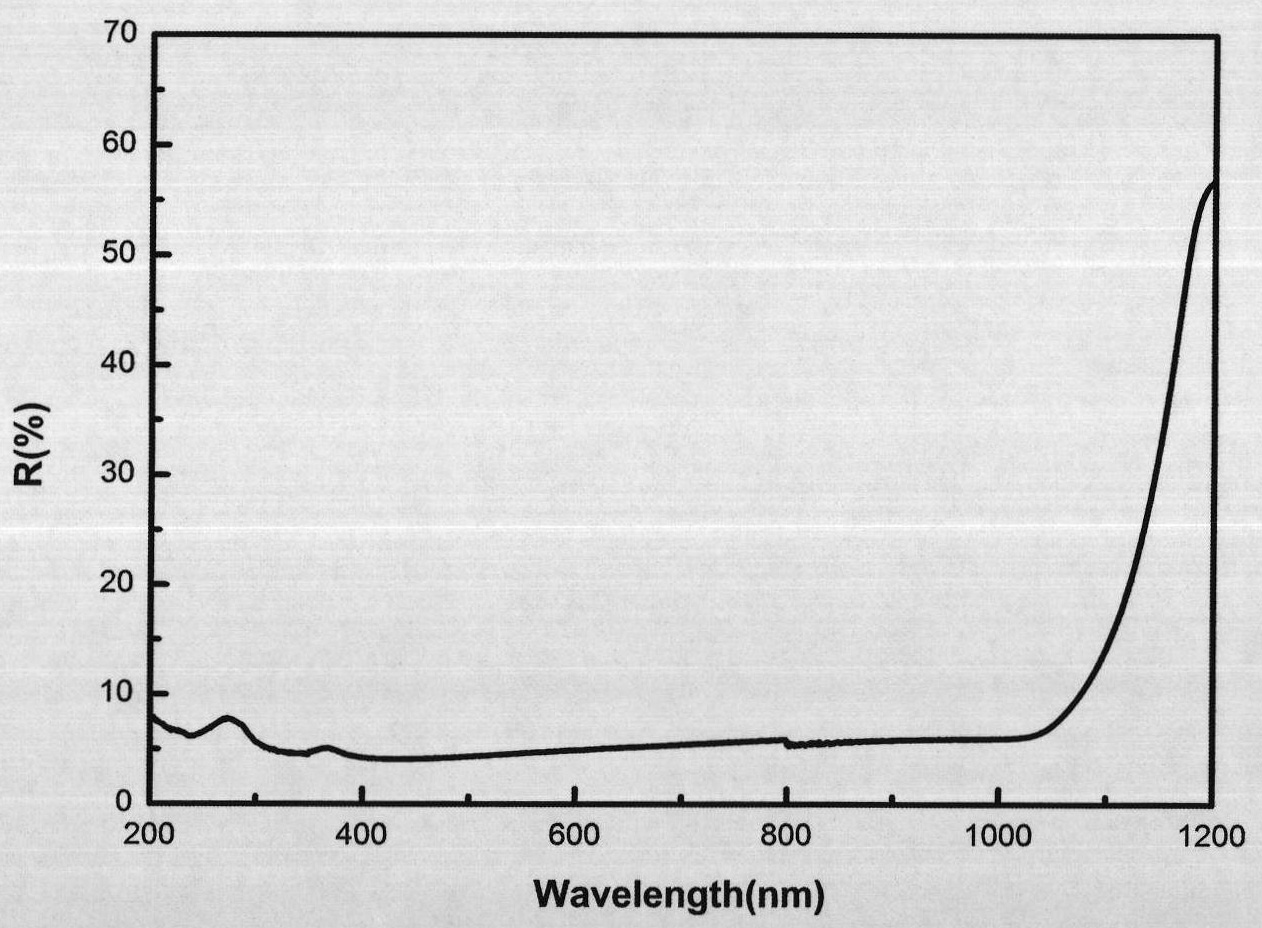

[0053] Clean the p-type Si(100) with a size of 125mm×125mm (resistivity 1~3Ωcm) with traditional technology, and immerse the silicon wafer in a mixed solution containing 5.1mol / L hydrofluoric acid and 0.03mol / L silver nitrate , etch for 4min. Then the silicon wafer is taken out, ultrasonically cleaned with nitric acid to remove the metal covered on the surface, then ultrasonically cleaned with deionized water, and then dried with high-purity nitrogen to obtain black silicon with low reflectivity. The obtained reflectance is as image 3 shown.

Embodiment 3

[0055] Clean the p-type Si(100) with a size of 125mm×125mm (resistivity 1-3Ωcm) by traditional techniques, and immerse the silicon wafer in a mixed solution containing 5.1mol / L hydrofluoric acid and 0.03mol / L silver nitrate , etch for 5min. Then the silicon wafer is taken out, ultrasonically cleaned with nitric acid to remove the metal covered on the surface, then ultrasonically cleaned with deionized water, and then dried with high-purity nitrogen to obtain black silicon with low reflectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com