Antireflective film formation method, antireflective film, and film formation device

A technology of anti-reflection film and film forming method, which is applied in sputtering plating, ion implantation plating, coating, etc., and can solve problems such as inability to form a film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

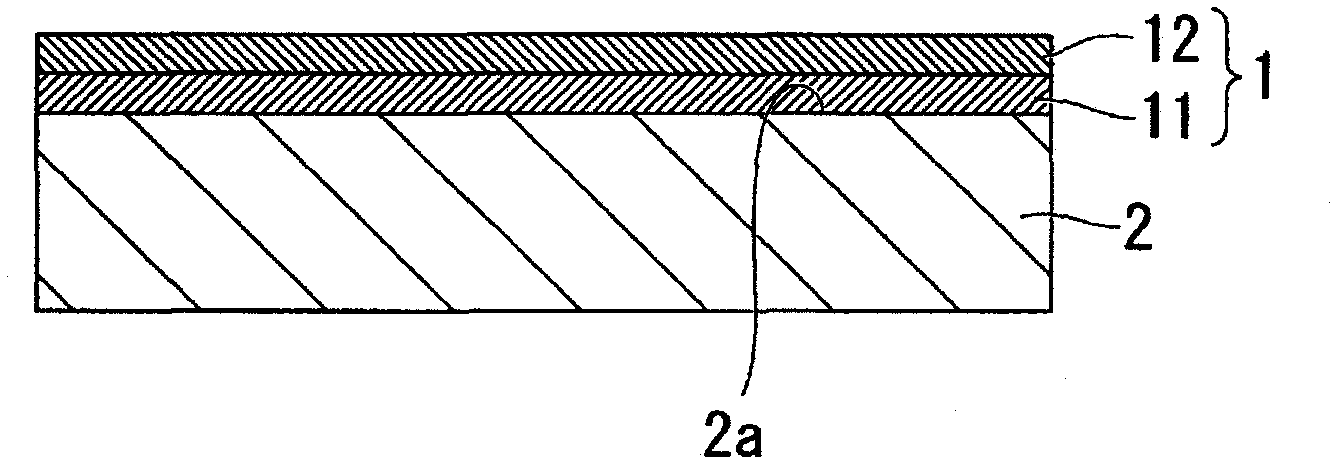

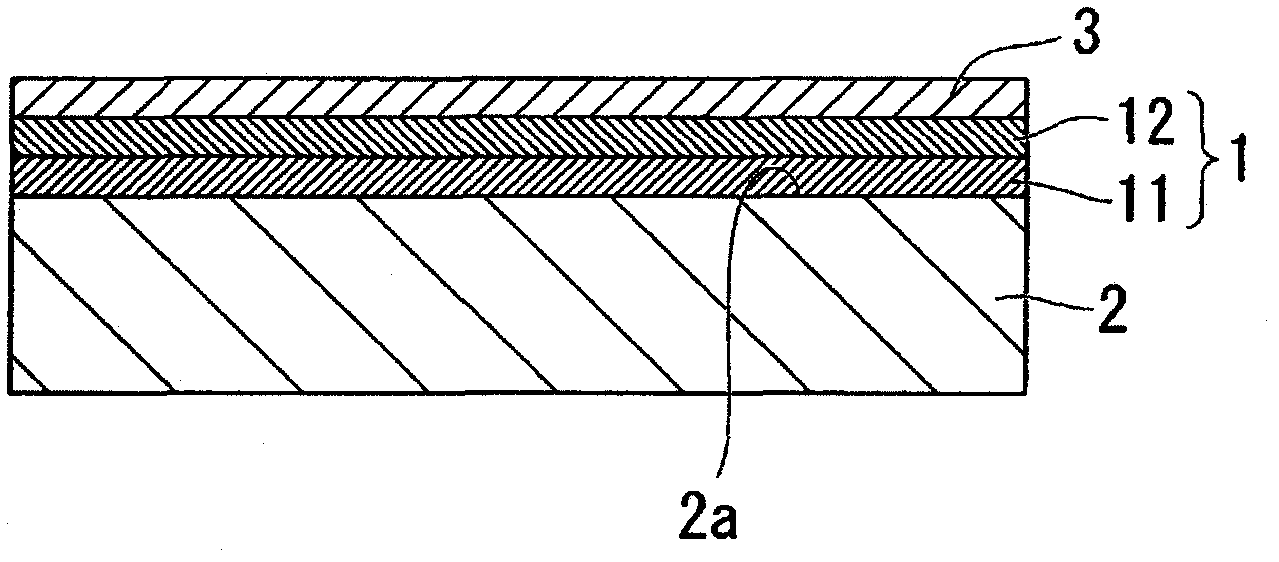

[0048] figure 1 It is a cross-sectional view showing the antireflection film according to the first embodiment of the present invention. The antireflection film 1 is formed on the surface 2a of the transparent substrate 2, having a laminated structure. The anti-reflection film 1 is laminated with multilayer indium oxide-based thin films having different refractive indices such as a transparent film 11 with a high refractive index and a transparent film 11 with a low refractive index such that the refractive index decreases sequentially from the surface 2a side of the transparent substrate 2 outward. Transparent film 12.

[0049] These indium oxide-based thin films are preferably used, for example, with In 2 o 3 -SnO 2 、In 2 o 3 -TiO 2 、In 2 o 3 - Indium oxide-based materials such as ZnO as the main component.

[0050] For example, in the case of using a laminated structure of indium oxide (ITO) added with tin, the transparent film 12 with a low refractive index such ...

no. 2 approach

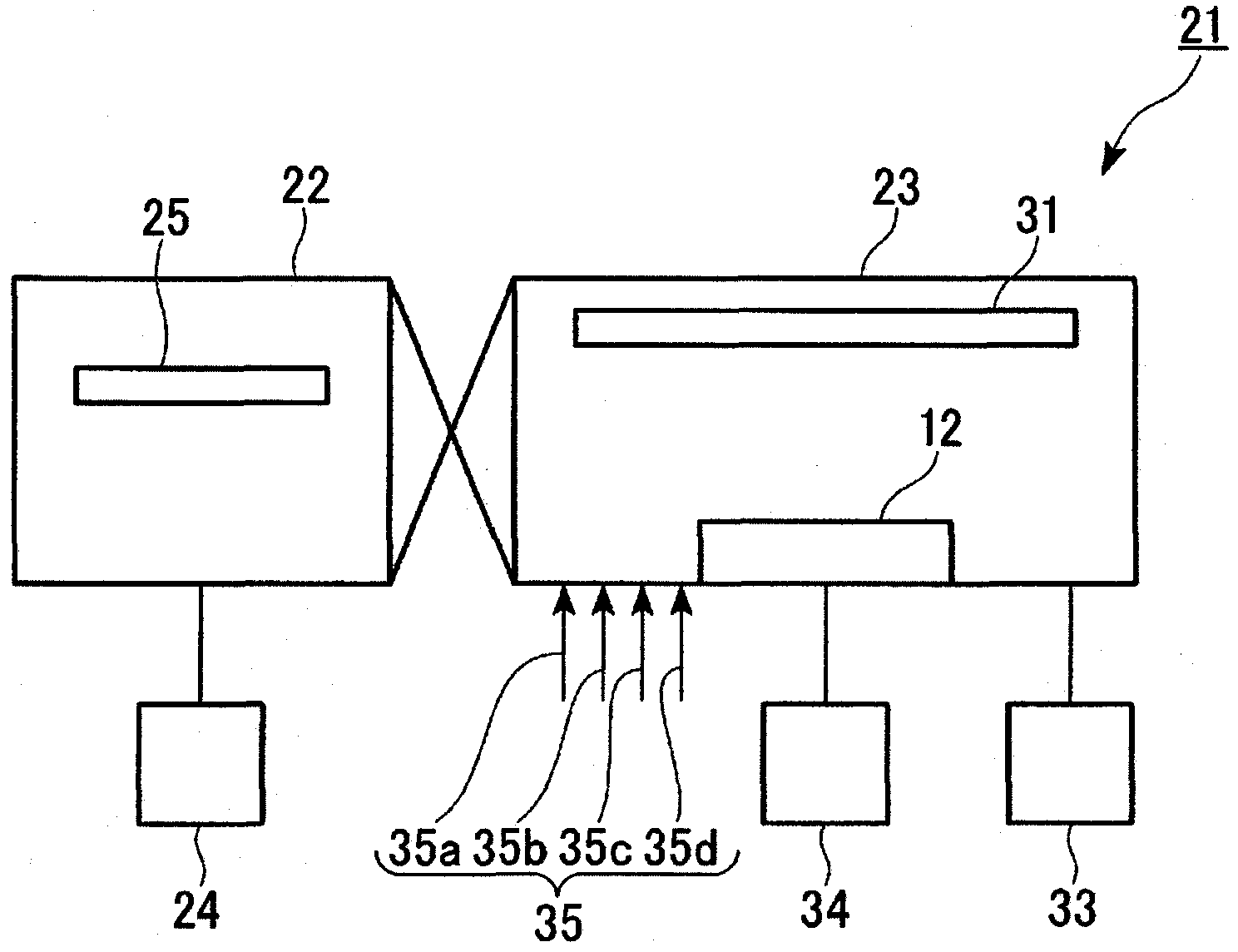

[0120] Figure 8 It is a sectional view of main parts showing a film forming chamber of a reciprocating magnetron sputtering device (film forming device) used for forming an antireflection film according to a second embodiment of the present invention.

[0121] The difference between this magnetron sputtering device 41 and the above-mentioned sputtering device 21 is that a side surface 23b of the film forming chamber 23 is vertically provided with a sputtering cathode mechanism (target sputtering cathode mechanism) which holds a target 27 of indium oxide-based material and generates a desired magnetic field. keep equipment)42.

[0122] The sputtering cathode mechanism 42 includes a rear plate 43 to which the target 27 is welded (fixed) with solder or the like, and a magnetic circuit (magnetic field generating device) 44 arranged along the back surface of the rear plate 43 . Magnetic circuit 44 is owing to produce horizontal magnetic field on the surface of target 27, so a plu...

no. 3 approach

[0128] Figure 9 It is a schematic configuration diagram showing a rotary sputtering apparatus according to a third embodiment of the present invention.

[0129] In the film formation chamber (vacuum container) 52 of the sputtering apparatus 51, the rotating body 54 which rotates about the center axis|shaft of this film formation chamber 52 is provided. On the outer peripheral surface of the rotating body 54, a substrate rack 53 ( Figure 9 in 4). Furthermore, on the inner surface of the film forming chamber 52, a plurality of cathodes 32 ( Figure 9 in 2). When the rotating body 54 is rotated about its axis and stopped at a position where the substrate holder 53 faces the cathode 32 , the substrate 26 supported by the substrate holder 53 of the rotating body 54 faces the target 27 held by the cathode 32 .

[0130] The film forming chamber 52 is provided with a device which divides the chamber into two sputtering regions S 1 , S 2 The partition plate 55. In both sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com