Coating solution for forming transparent film and substrate with transparent film

A coating liquid and film technology, applied in coatings, conductive coatings, anti-reflection coatings, etc., can solve problems such as uneven existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

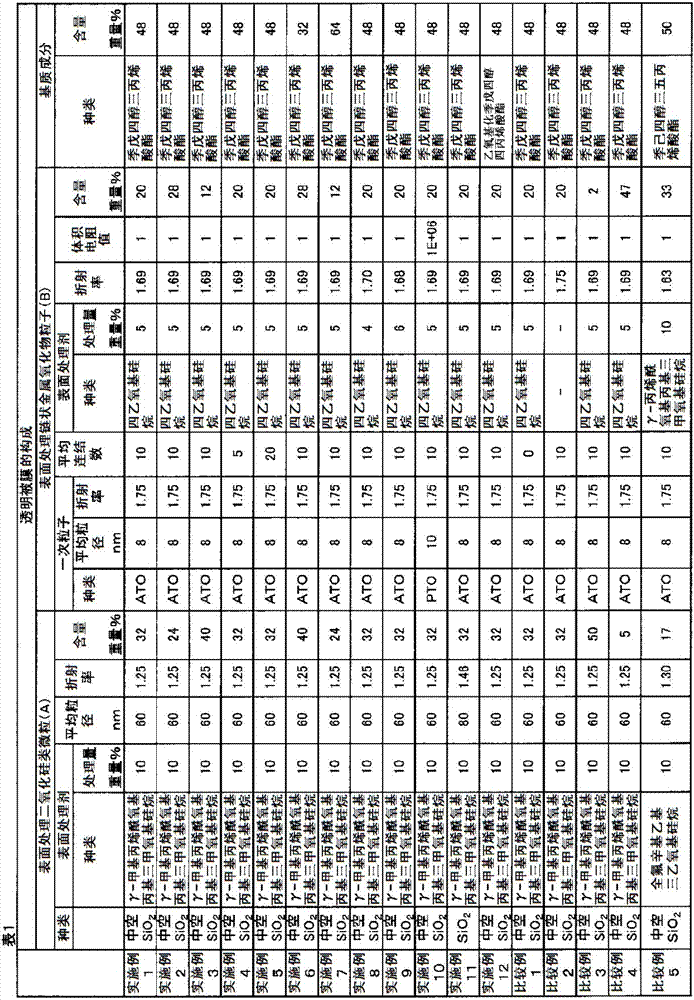

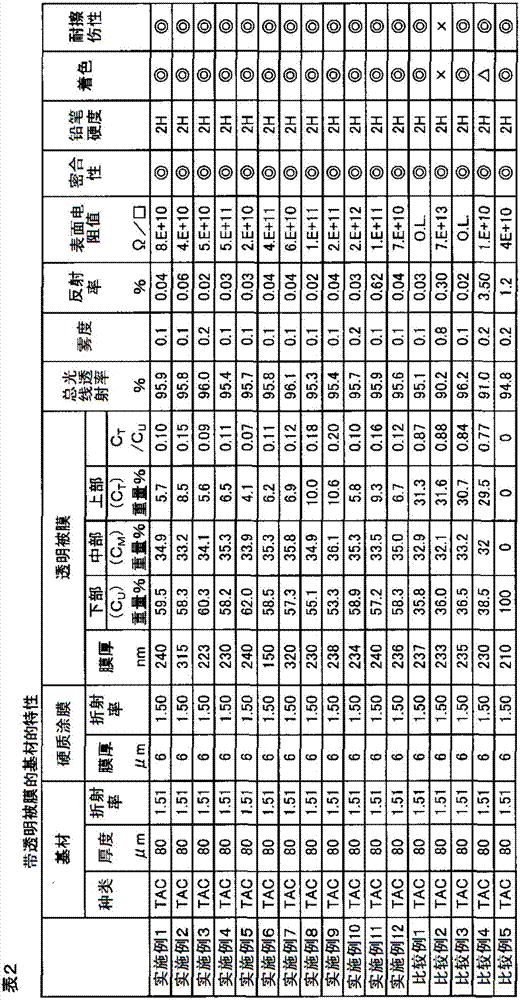

Examples

Embodiment 1

[0170] [Example 1] Preparation of Surface-treated Silica Microparticles (A-1) Dispersion

[0171] Silica-alumina sol (manufactured by Nikke Catalyst Chemicals Co., Ltd.: USBB-120, average particle size 25nm, SiO 2 ·Al 2 o 3 Concentration 20% by weight, Al in solid content 2 o 3 Content 27% by weight) 3680g of pure water was added to 120g, the temperature was raised to 95°C, and SiO was added while maintaining the temperature. 2 Concentration is 15% by weight of sodium silicate aqueous solution 2100g and Al 2 o 3 Concentration is 2100g of sodium aluminate aqueous solution 5% by weight, obtains SiO 2 ·Al 2 o 3 Composite oxide microparticles (1-1) (average particle diameter: 43 nm) dispersion. Al at this time 2 o 3 / SiO 2 The molar ratio was 0.2. The pH of the reaction liquid at this time was 12.0.

[0172] Added with SiO 2 The concentration is 15% by weight of sodium silicate aqueous solution 8800g and Al 2 o 3 Concentration is 5% by weight sodium aluminate aq...

Embodiment 2

[0222] Preparation of Coating Solution (2) for Transparent Film Formation

[0223] A mixed alcohol of methanol, ethanol and isopropanol (Nippon Alcohol Trading Co. Made by the company: 76.76 g of Solmix AP-11), 13.24 g of PGME, and 4.10 g of a dispersion of surface-treated chain-shaped conductive metal oxide particles (B-1) prepared in the same manner as in Example 1 with a solid content concentration of 20.5% by weight , 1.44 g of pentaerythritol triacrylate (manufactured by Kyoeisha Chemical Co., Ltd.: ライトアクリレートPE-3A, resin concentration 100% by weight) and 0.95 g of a photoinitiator (manufactured by Ciba Seika Co., Ltd.: イルガキュュア184), fully mixed, A coating liquid (2) for forming a transparent film having a solid content concentration of 3% by weight was prepared.

[0224] Preparation of substrate (2) with transparent film

[0225] In Example 1, except having used the coating liquid (2) for transparent film formation, the base material (2) with a transparent film was p...

Embodiment 3

[0226] [Example 3] Preparation of Coating Solution (3) for Transparent Film Formation

[0227] A mixed alcohol of methanol, ethanol and isopropanol (Nippon Alcohol Trading Co. Produced by the company: Solmix AP-11) 76.76g, PGME 13.24g, 1.76g of a dispersion of surface-treated chain-shaped conductive metal oxide particles (B-1) prepared in the same manner as in Example 1 with a solid content concentration of 20% by weight , 1.44 g of pentaerythritol triacrylate (manufactured by Kyoeisha Chemical Co., Ltd.: ライトアクリレートPE-3A, resin concentration 100% by weight) and 0.95 g of a photoinitiator (manufactured by Ciba Seika Co., Ltd.: イルガキュュア184), fully mixed, A coating liquid (3) for forming a transparent film having a solid content concentration of 3% by weight was prepared.

[0228] Preparation of substrate (3) with transparent film

[0229] In Example 1, except having used the coating liquid (3) for transparent film formation, the base material (3) with a transparent film was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com