Hard-coat optical film, polarizing plate and image display device

A technology of hard coating and optical film, which can be used in coatings, optics, optical components, etc., and can solve the problems of high water absorption and high birefringence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the hard coat optical film of the present invention comprises the addition of polyurethane (meth)acrylate oligomers with functionalities ranging from 6 to 15 in the (meth)acrylate composition, at least one functionality not less than 3 ( Meth)acrylate monomers, at least one (meth)acrylate monomers with a functionality of less than 3, and initiators are mixed evenly with appropriate solvents to form a hard coat solution, and leveling can be added to the hard coat solution as required agent; the hard coat solution is coated on the PMMA substrate, dried to remove the solvent, and then cured by radiation or electron beams to form a hard coat on the PMMA substrate to obtain a hard coat optical film.

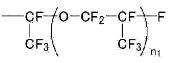

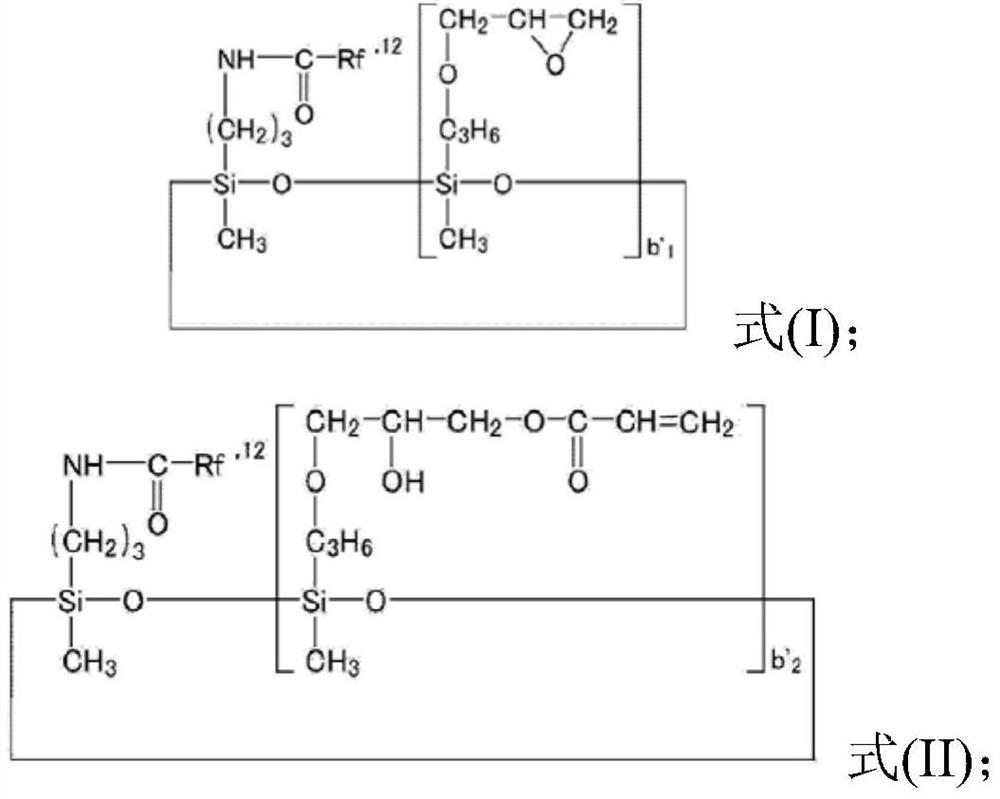

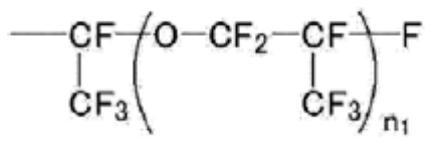

[0058] A low-refractive-index layer can be further formed on the aforementioned hard coat layer of the present invention, and the low-refractive-index layer is made of binder resin, hollow silicon dioxide nanoparticles, initiator, and containing the afo...

Embodiment 1

[0066] Embodiment 1: Preparation of hard coat optical film

[0067]39 parts by weight of urethane acrylate oligomer (functionality 6, molecular weight about 1,520, viscosity about 25,000 cps (25°C), purchased from Miwon, Korea), 4.5 parts by weight of pentaerythritol triacrylate (PETA), 12 parts by weight Parts of dipentaerythritol hexaacrylate (DPHA), 6 parts by weight of hexanediol diacrylate (HDDA), 4 parts by weight of photoinitiator (Chemcure-184, purchased from Hengqiao Industry, Taiwan, China), 24.5 parts Parts by weight of ethyl acetate (EAC) and 75 parts by weight of n-butyl acetate (nBAC) were mixed and stirred for 1 hour to form a hard coating solution. Then the aforementioned hard coat solution is coated onto a 40 micron PMMA substrate, and then the substrate coated with the hard coat solution is dried in an oven at 90° C. for 30 seconds, and then dried at 40 mJ / cm under a nitrogen atmosphere. 2 Radiation doses of UV lamps for photocuring. In this way, a hard coa...

Embodiment 2

[0068] Embodiment 2: Preparation of hard coat optical film

[0069] 39 parts by weight of urethane acrylate oligomer (functionality 15, molecular weight about 3,600, viscosity about 4,700 cps (60°C), purchased from Chemton, Korea), 4.5 parts by weight of pentaerythritol triacrylate (PETA), 12 parts by weight Parts of dipentaerythritol hexaacrylate (DPHA), 6 parts by weight of hexanediol diacrylate (HDDA), 4 parts by weight of photoinitiator (Chemcure-184, purchased from Hengqiao Industry, Taiwan, China), 24.5 parts Parts by weight of ethyl acetate (EAC) and 75 parts by weight of n-butyl acetate (nBAC) were mixed and stirred for 1 hour to form a hard coating solution. Then the aforementioned hard coat solution is coated onto a PMMA substrate of 40 microns, and then the PMMA substrate coated with the hard coat solution is dried in an oven at 90° C. for 30 seconds, and then dried at a rate of 40 mJ / cm under a nitrogen atmosphere. 2 Radiation doses of UV lamps for photocuring. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com