Cyanogen-free gilding solution for electro-gilding

A cyanide-free gold plating and electroplating technology, which is applied in the field of electroplating gold technology, can solve the problems of coarse crystals, easy oxidation of sulfite, and high cost of plating solution, so as to reduce damage and benefit the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

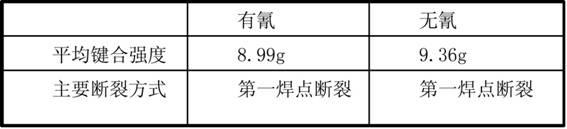

[0012] Take cyanide-free gold plating as an example: copper parts are nickel-plated with gold (Au 2μm).

[0013] Process flow:

[0014] chemical degreasing Wash 1 electrolytic degreasing Wash 2 pickling Wash 3 Wash 4 Electroplated Nickel Wash 5 activate Washed 6 pure water wash Cyanide-free gold plating Washed 7 pure water wash dry.

[0015] Except for the cyanide-free gold plating process, other processes and process conditions are the same as conventional electroplating, and the relevant formulas and parameters are as follows:

[0016] The chemical degreasing process conditions are as follows:

[0017] Sodium hydroxide 12g / L

[0018] Anhydrous Sodium Carbonate 25 / L

[0019] sodium phosphate 60 / L

[0020] Surfactant 1ml / L

[0021] Temperature 90°C

[0022] The time is 15 minutes.

[0023] Electrolytic degreasing process conditions are as follows:

[0024] So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com