Construction method of pervious cement concrete

A technology of permeable cement and construction method, which can be applied to cohesive pavement paved on site, roads, road repairs, etc. It can solve the problems of permeable cement concrete pavement loss, weaken water permeability, and destroy pore structure, etc., to increase road safety Sex and traffic comfort, construction quality control is easy, and the effect of comfortable traffic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

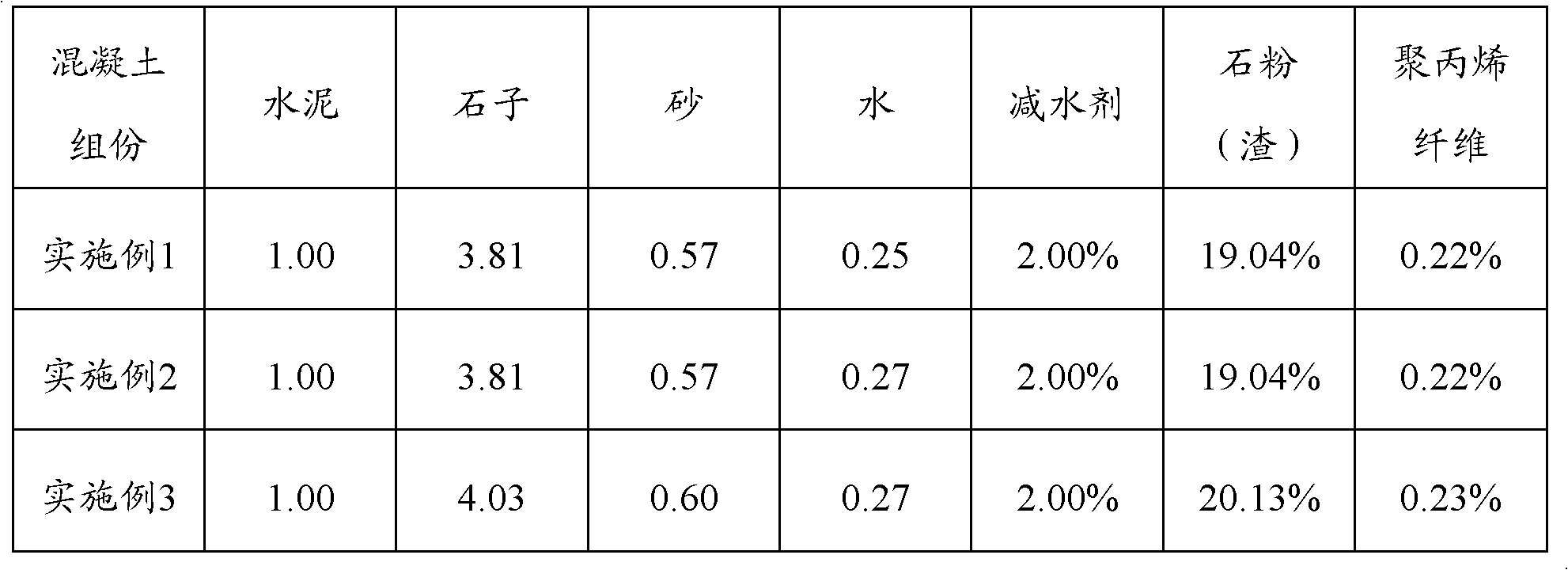

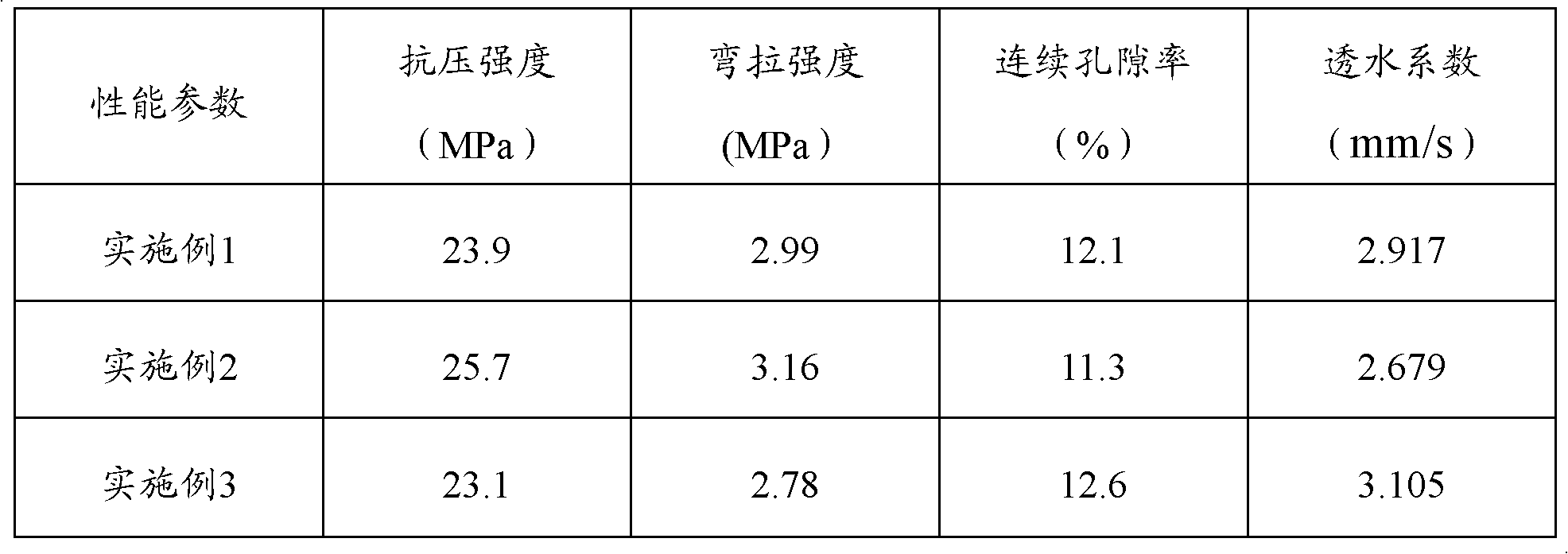

[0014] The invention relates to a permeable cement concrete. The permeable cement concrete is composed of cement, stones, sand, water, water reducer, stone powder (slag) and polypropylene fibers. The amount of cement per cubic meter of permeable cement concrete is 300kg-400kg. The sand rate is 10%-20%, and it is made by uniformly mixing according to the following weight ratio: cement: gravel: sand: water: water reducer: stone powder (slag): polypropylene fiber The weight ratio is 1: 3.5 ~ 5.5: 0.5 ~ 0.9: 0.2-0.35: 0.01-0.02: 0.15-0.25: 0.002-0.003. Add the components in the above ratio to the mixer, mix them evenly to make concrete, and then carry out paving construction.

[0015] The present invention also relates to the construction method of the permeable cement concrete, comprising the following steps:

[0016] Step 100, adding each component of the permeable cement concrete into a concrete mixer according to a certain ratio, and after stirring for a certain period of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com