Large composite material skinned die and manufacturing method thereof

A composite material and skin technology, which is applied in the field of large-scale skin molds and their manufacturing, can solve the problem that the air between large areas cannot be completely eliminated, the air tightness requirements of composite parts cannot be met, and the size and area of composite skins are large. and other problems, to achieve the effect of eliminating micro-pit porosity defects, improving surface quality and airtight reliability, improving surface quality and mold service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

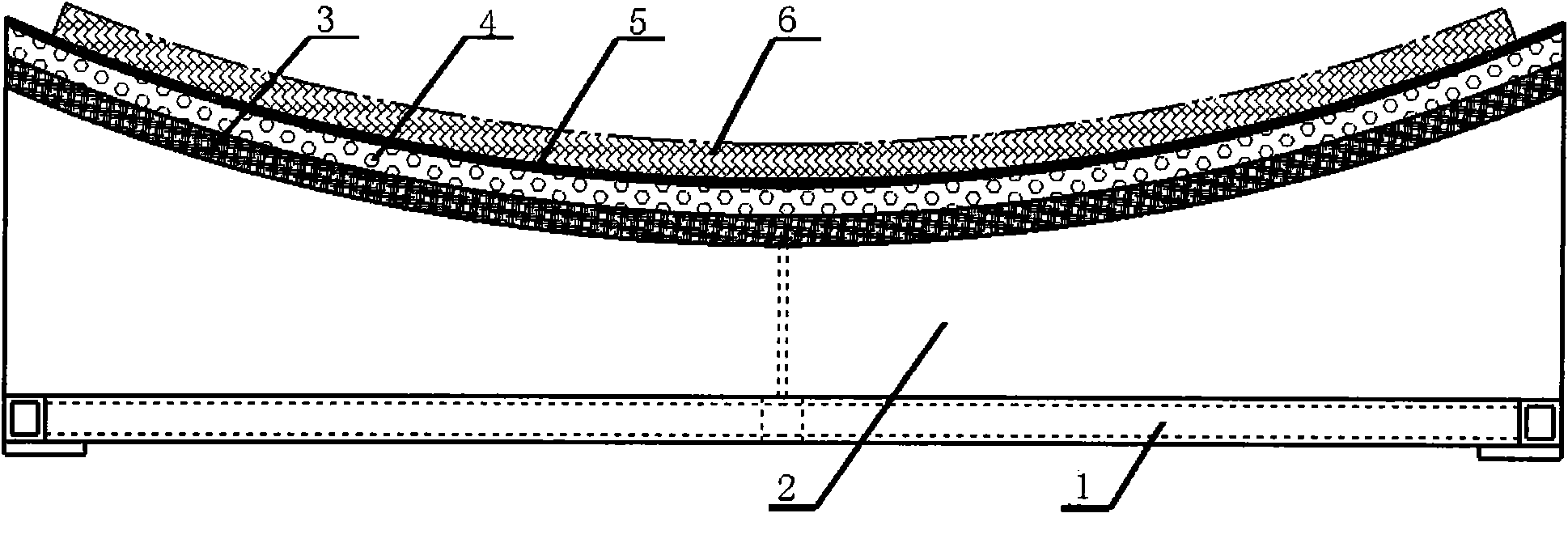

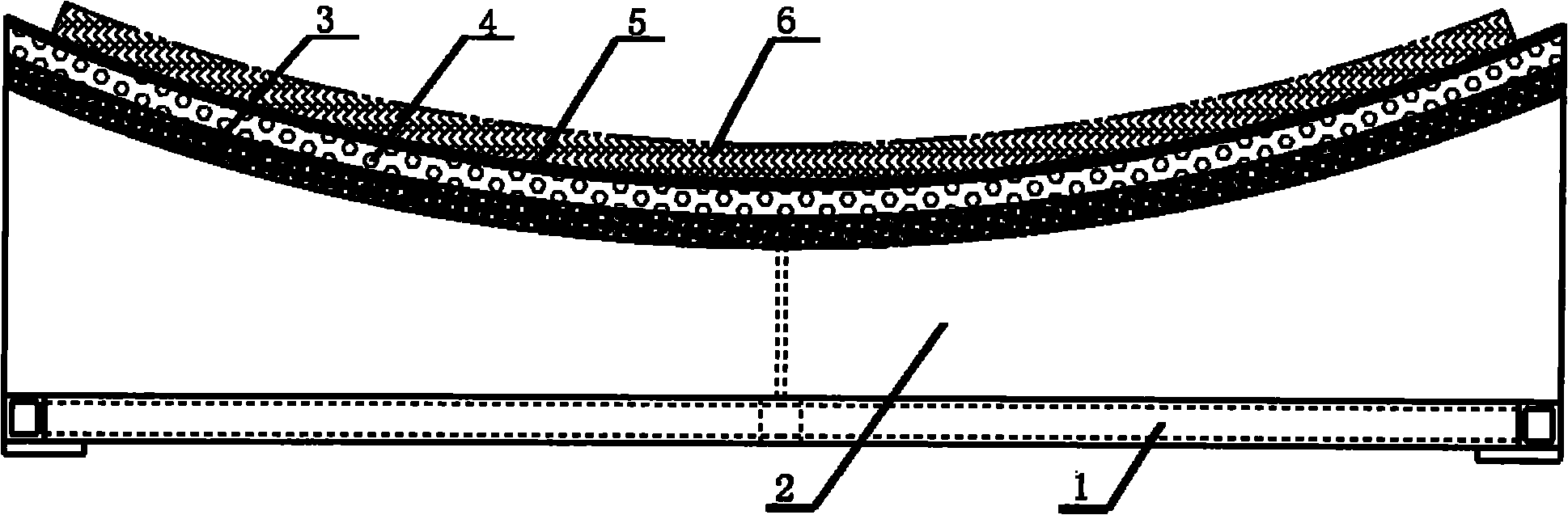

[0010] refer to figure 1 . The ultra-large composite material mold for rail vehicles of the present invention is composed of: a support base 1 welded by combining rectangular steel, combined and welded by criss-cross steel plates, and welded and positioned on the support base 1 to form a large-scale skin working surface The support frame 2 consists of a fiberglass layer 3 with a skin profile, an epoxy resin layer 4 bonded to the fiberglass layer 3, and a fluoropolyurethane matte enamel varnish layer 5 sprayed on the surface of the epoxy resin layer 4. The working surface of the FRP layer 3 is segmented according to a length of about 2 meters, and is bonded and fixed on the above-mentioned support frame 2 by epoxy resin. The segmented joints of FRP 3 are filled and connected with epoxy resin; the epoxy resin layer 4 is bonded to the FRP layer 3 and has the surface accuracy requirements of composite parts, and the fluorine polyurethane matt porcelain varnish layer 5 is in The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com