Horizontal production process of polyurethane rubber roller

A production process and polyurethane technology, which is applied in the field of horizontal production process of polyurethane rubber rollers, can solve problems such as the large difference between temperature and rubber material temperature, poor uniformity of physical properties of rubber rollers, frequent mold movement frequency, etc., and achieve stable casting quality. , The appearance quality is good, the effect of avoiding bubbles and lack of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

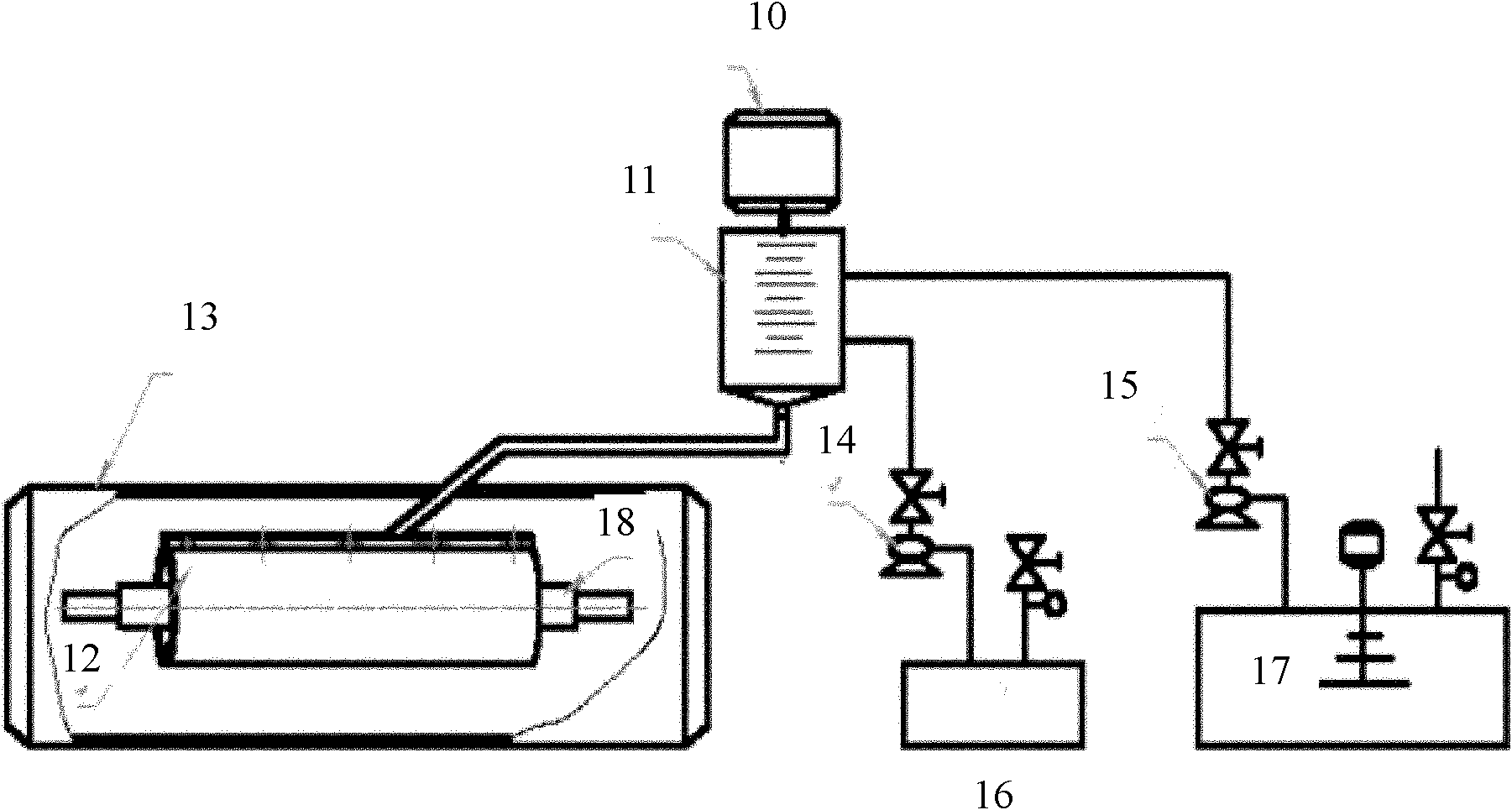

[0032] Embodiment 1: the polyester polyol (H 2 O%≤0.03%, the hydroxyl value is 53~59mgKOH / g) and DBP in proportion (100:6) into the reactor, heated and melted, and dehydrated at 100℃~140℃, -0.1MPa for 3h; after dehydration, add in proportion TDI (TDI:polyester polyol = 22.6:100), stirred at 80-85°C for 2h, then degassed at -0.1MPa for 2h.

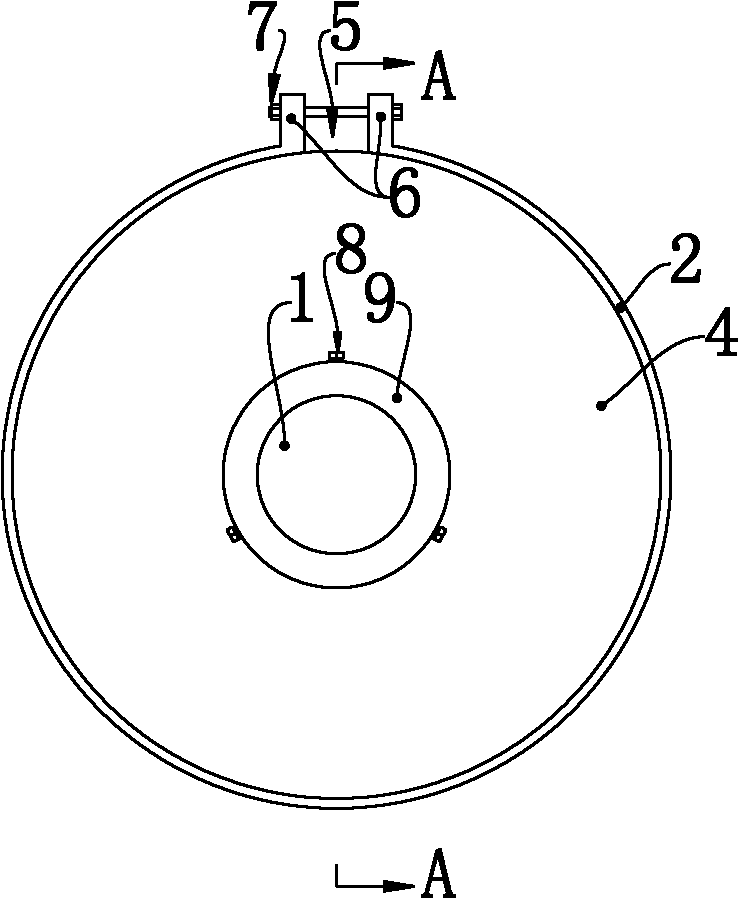

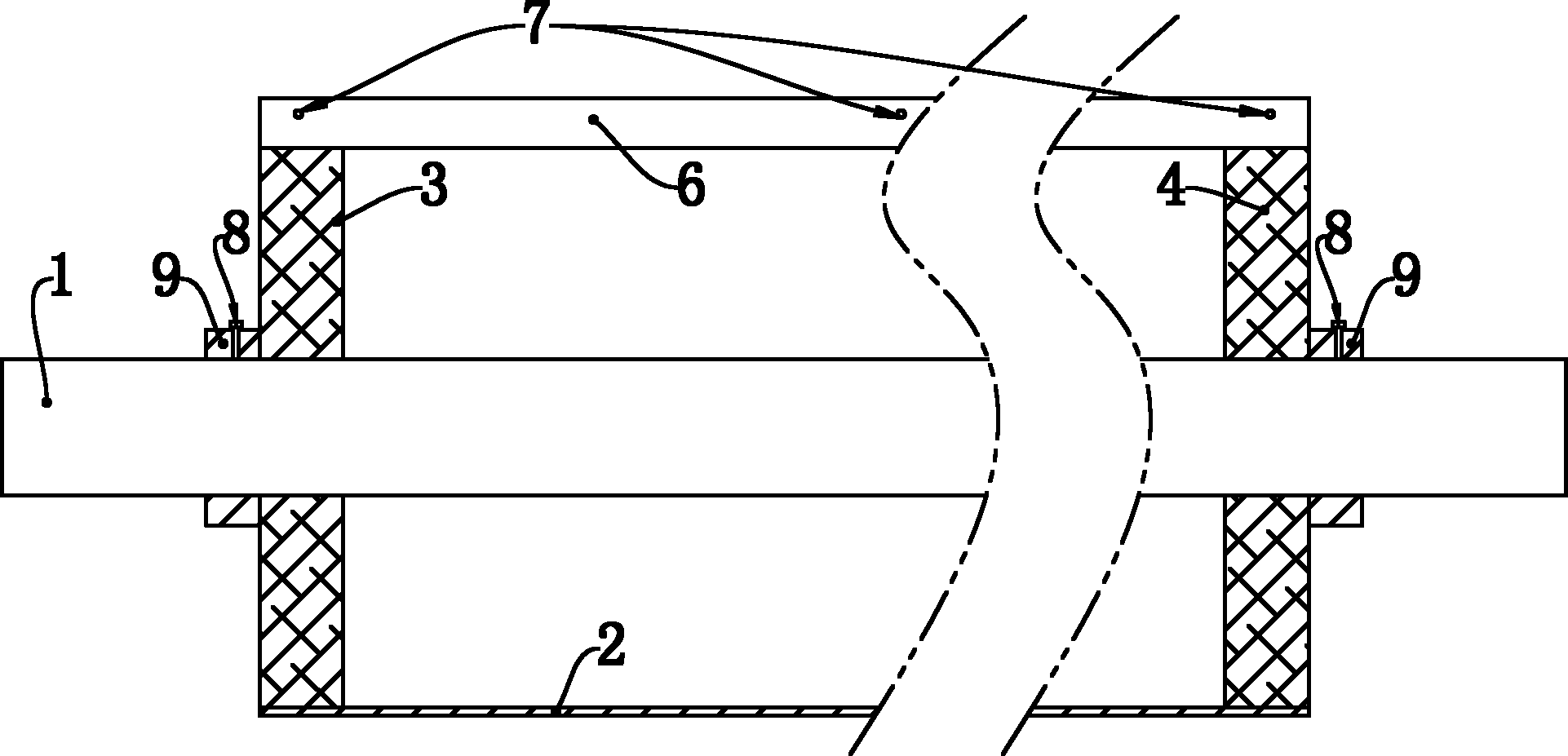

[0033] The roller core needs to be blasted with 8-mesh corundum before use, and 120 # Clean the surface of the roller core with solvent gasoline, and then paint with Kemlok (CH218). Apply silicone grease to the inside of the mold. Put the roller core into the mold to form a rubber roller casting mold, and heat it in an oven at 80-85°C for 5 hours.

[0034] The synthesized prepolymer is introduced into the pouring machine, mixed with MOCA in a weight ratio (MOCA:prepolymer=11.35:100) for pouring, and the oven temperature is maintained at 80-85°C during pouring. The poured polyurethane rubber roller is baked in an oven at 90-120°C for 8-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com