Energy-saving and consumption-reducing hydraulic system with multistage pressure control for large hydraulic machine

A hydraulic system and hydraulic press technology, applied in the field of pressure multi-level control hydraulic system, can solve the problems of reduced pressure regulation accuracy, increased energy consumption, and reduced overall machine efficiency, avoiding energy consumption, reducing leakage, and improving pressure regulation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

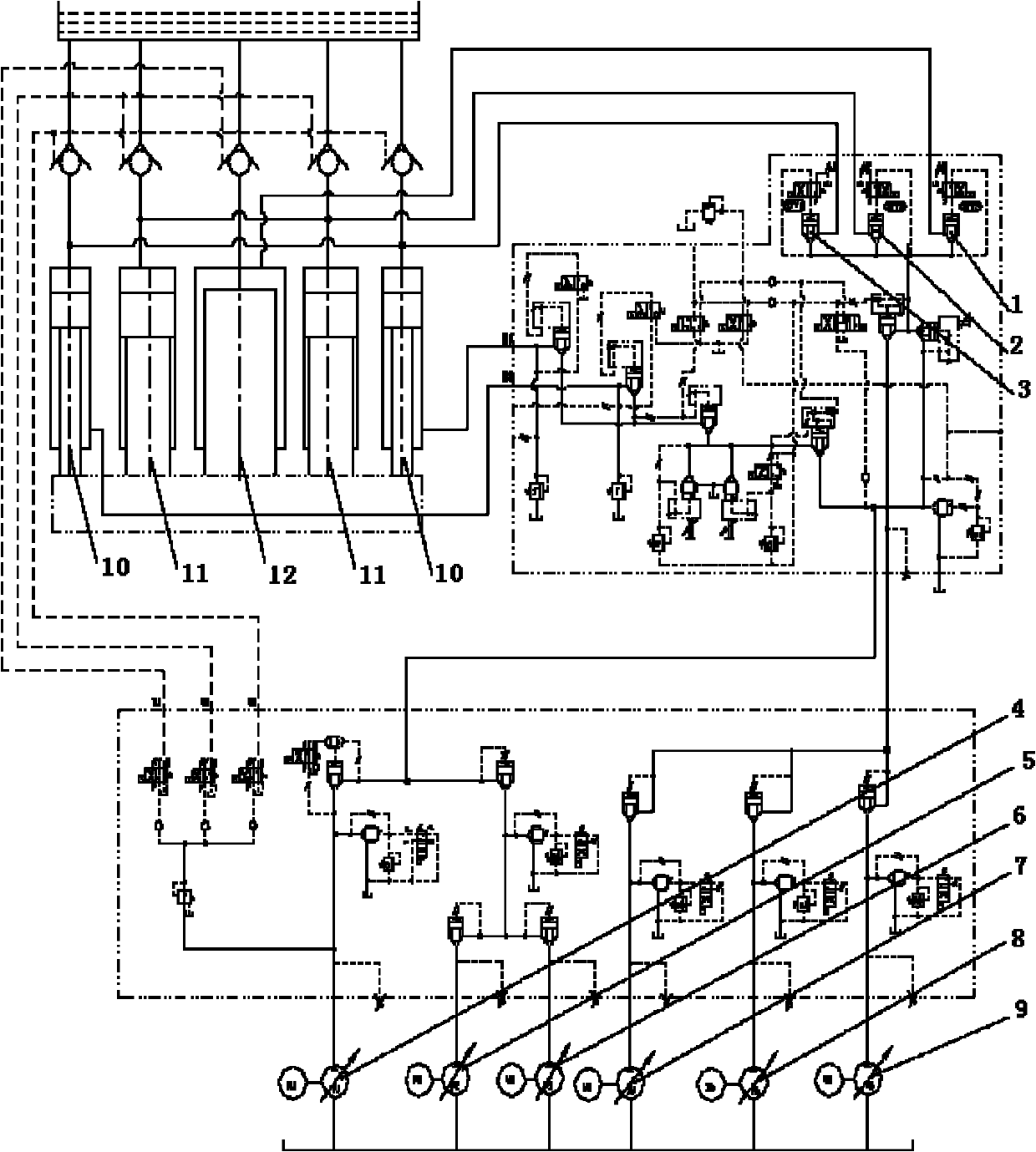

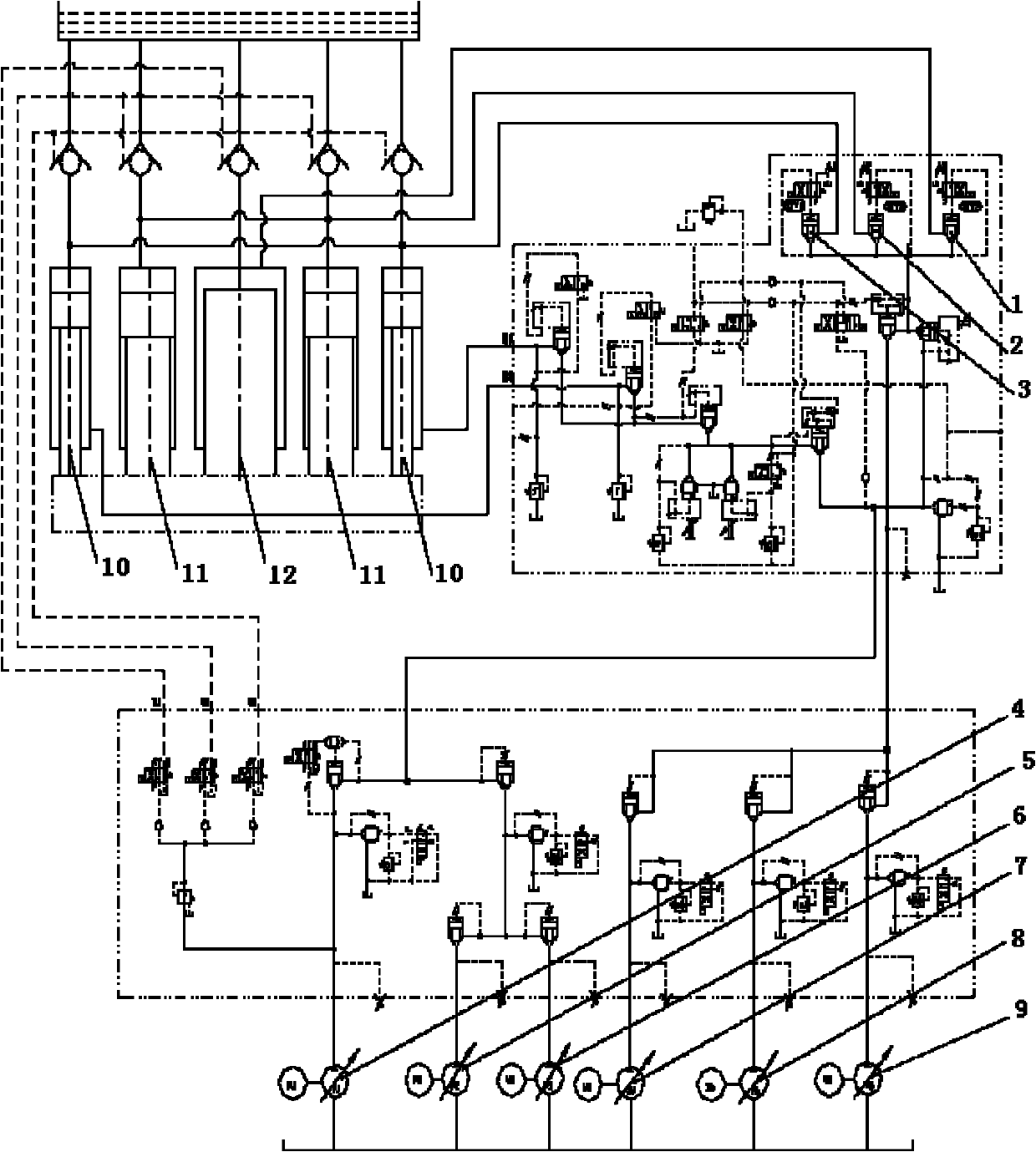

[0015] Referring to the attached drawings, the pressure multi-stage control hydraulic system for energy-saving consumption of large hydraulic presses, in the large hydraulic press system, the principle of group control of oil cylinders can be used on equipment with three cylinders and above. The main oil cylinder is a plunger cylinder, and the rest For the piston cylinder, there are two 500-ton oil cylinders 10, two 1,000-ton oil cylinders 11, and 2,000-ton oil cylinders 12. Three kinds of plug-ins are designed in the system, namely No. 1 plug-in 1, No. 2 plug-in 2, No. 3 plug-in 3, Each plug-in is controlled by electromagnets 3Y7.1, 3Y7.2, 3Y7.3 to switch off and on, so as to achieve independent control of the oil circuit in the upper chamber of the main cylinder and the side cylinder, and combine them into different main tonnages to meet different requirements. According to the process requirements, the attached drawings can be matched into five main tonnages of 1000T, 2000T,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com