Automatic alignment system of inclined contact type laser gyro

A laser gyroscope and contact technology, which can be used in closed-circuit television systems, Sagnac effect gyroscopes, and the method of comparing with reference electrical parameters. and other problems, to achieve the effect of accurate loss value, precise positioning, and reduction of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

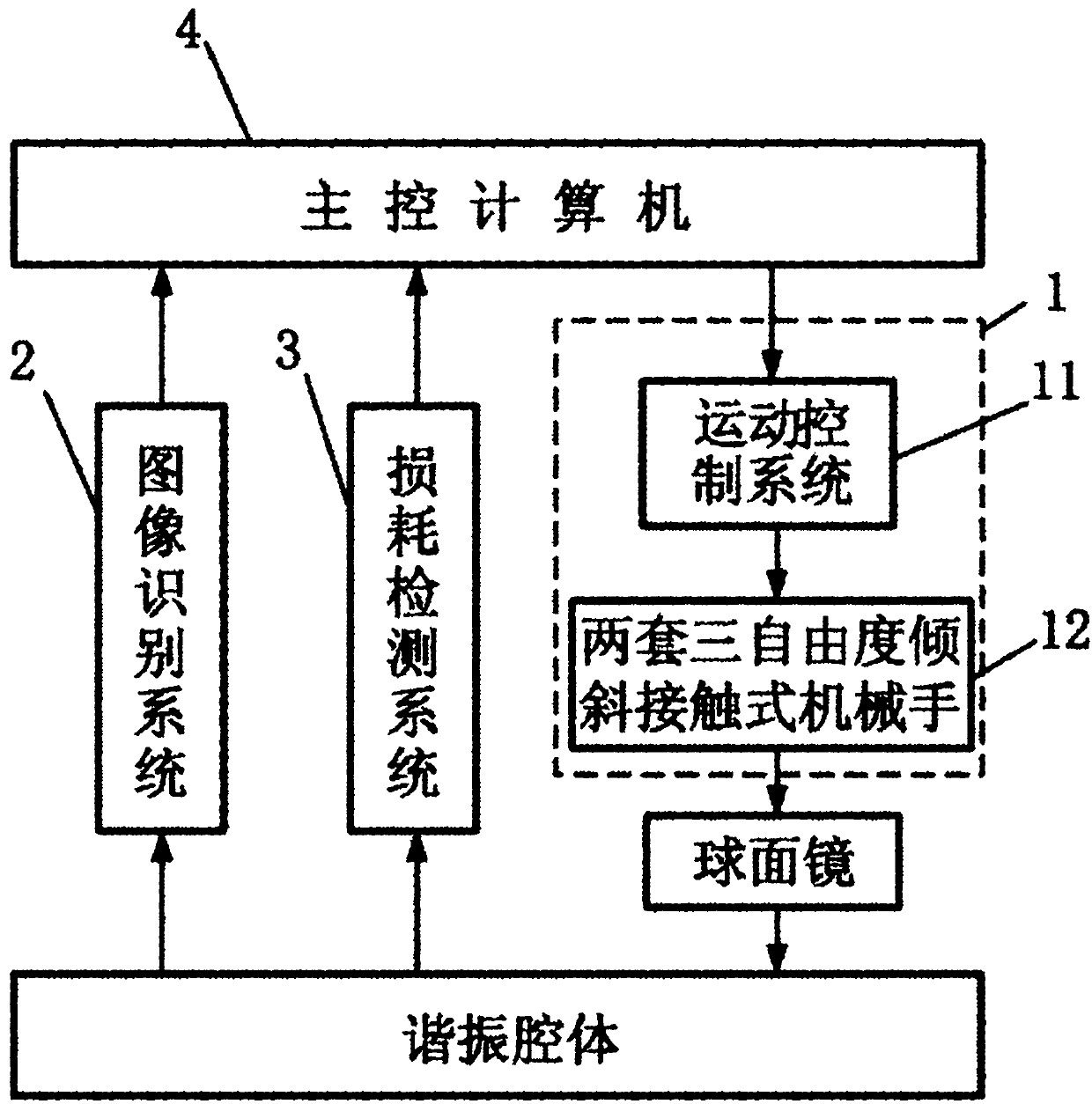

[0012] Specific implementation mode one: combine Figure 1 to Figure 7 Describe the present embodiment, the inclined contact laser gyro automatic cavity adjustment system in this embodiment is used to adjust the positions of the two station spherical mirrors on the optical glue surface of the resonant cavity;

[0013] It consists of an inclined contact cavity adjustment mechanism and its control system 1, image recognition system 2, loss detection system 3 and main control computer 4;

[0014] Inclined contact cavity adjustment mechanism and its control system 1 are composed of a motion control system 11 and two sets of three-degree-of-freedom inclined-contact manipulators 12. The two sets of three-degree-of-freedom inclined-contact manipulators 12 have the same structure and are respectively used for resonant cavity Adjustment of the two-station spherical mirrors on the body;

[0015] The image recognition system 2 is used to capture the aperture of the resonant cavity and t...

specific Embodiment approach 2

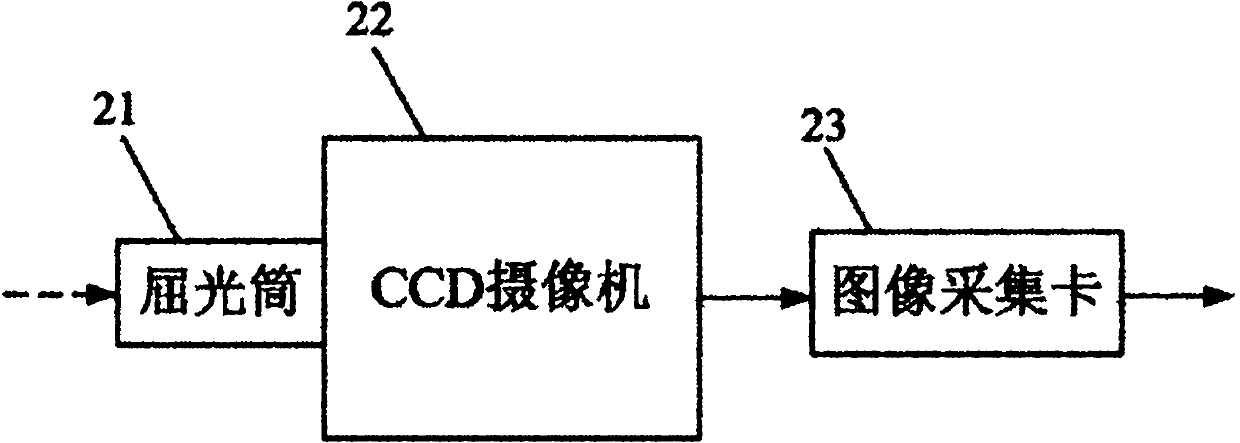

[0020] Specific implementation mode two: combination figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the image recognition system 2 is made up of a diopter 21, a CCD camera 22 and an image acquisition card 23, and the lens on the CCD camera 22 is equipped with a diopter 21, The output beam of the resonant cavity is incident into the lens of the CCD camera 22 through the diopter 21, the image signal output end of the CCD camera 22 is connected to the image signal input end of the image acquisition card 23, and the image data output end of the image acquisition card 23 is connected to the main The image data input terminal of the control computer 4. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

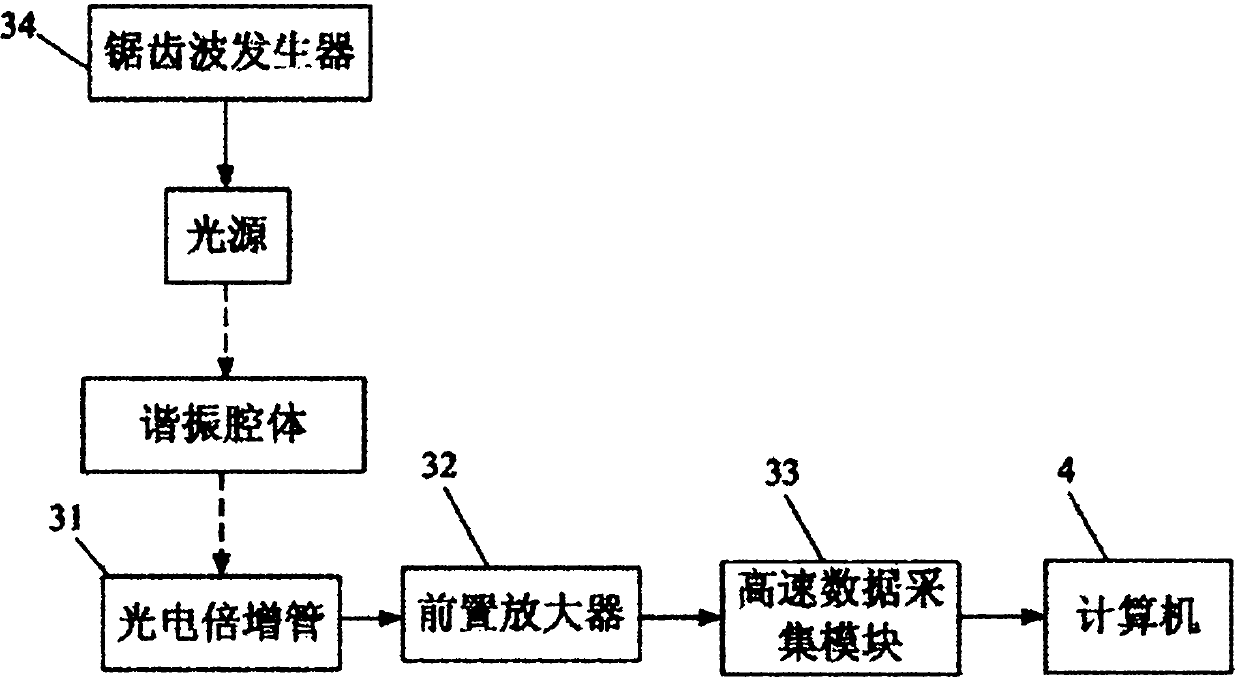

[0021] Specific implementation mode three: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment one or two is that the loss detection system 3 is composed of a photomultiplier tube 31, a preamplifier 32, a high-speed data acquisition module 33 and a sawtooth wave generator 34, and the sawtooth wave generator 34 drives the light source to generate reference light, the reference light is light that is periodically scanned within a certain frequency range, the reference light is incident into the resonant cavity, and forms a stable oscillation in the cavity, and the collection end of the photomultiplier tube 31 collects The output light of the resonant cavity, and the output light is amplified and converted into an electrical signal and then output to the preamplifier 32, the preamplifier 32 outputs the signal to the high-speed data acquisition module 33, and the high-speed data acquisition module 33 outputs the signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com