High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

A radioactive waste liquid and cement solidification technology, which is applied in the field of solidification treatment and radioactive waste disposal, can solve the problems of easy bleeding, high leaching rate, and short coagulation time, so as to reduce the generation of microcracks, reduce the heat of hydration, The effect of lowering the core temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

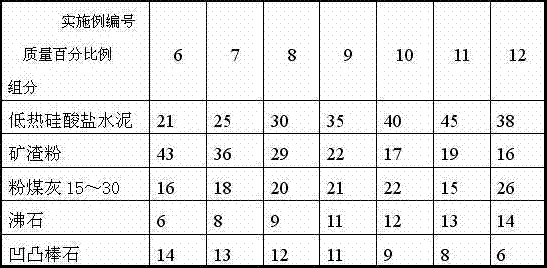

Examples

Embodiment 1

[0039] A high-salt, high-alkali, medium-low level radioactive waste cement solidified body and a preparation method thereof, comprising:

[0040] According to the ratio of 42.5 grade low-heat Portland cement: slag powder: fly ash: zeolite: attapulgite (palygorskite) = 40wt.%: 20wt.%: 20wt.%: 10wt.%: 10wt.% (wt .% is the mass percentage, the same below) Weigh the materials and mix them to make the curing material. Based on the curing material, weigh 0.1% cellulose ether, 1.0% (in which Na 2 O meter) water glass with a modulus of 2.5 to 3.5 were placed in the same container. According to the ratio of medium and low-level radioactive waste liquid with a salt content of 200g / L and a pH value > 14: solidified material (hereinafter referred to as the liquid-solid ratio) = 0.65, measure the radioactive waste liquid; take the radioactive waste liquid and add it to the above container Stir in a container with curing material, water glass, and cellulose ether for 10 minutes to obtain ...

Embodiment 2

[0042] A high-salt, high-alkali, medium-low level radioactive waste cement solidified body and a preparation method thereof, comprising:

[0043] Weigh the material according to the ratio of 42.5 grade low-heat Portland cement: slag powder: fly ash: zeolite: attapulgite (palygorskite) = 30wt.%: 40wt.%: 15wt.%: 10wt.%: 5wt.% , mixed to make a curing compound. Based on the cured material, weigh 2.5% (based on the Na 2 O meter) water glass with a modulus of 2.5 to 3.5 and 0.1% cellulose ether were placed in the same container. According to the ratio of medium and low-level radioactive waste liquid with a salt content of 300g / L and a pH value > 14: solidified material (hereinafter referred to as the liquid-solid ratio) = 0.65, measure the radioactive waste liquid; take the radioactive waste liquid and add it to the above container Stir in a container with curing material, water glass, and cellulose ether for 10 minutes to obtain a uniform mixed slurry. The fluidity of the mixed...

Embodiment 3

[0045] A high-salt, high-alkali, medium-low level radioactive waste cement solidified body and a preparation method thereof, comprising:

[0046] a. Ingredients: High-salt, high-alkali, medium-low level radioactive waste liquid and solidified material in the ratio of high-salt, high-alkali, medium-low level radioactive waste liquid: solidified material = 0.75:1 by mass ratio, and the modulus is 2.5-3.5. Na in water glass 2 The water glass of solidified material quality 3% of O meter, gets the cellulose ether of solidified material quality 0.5%;

[0047] The components and mass percentages of the curing material include: 40% low-heat Portland cement, 15% slag powder, 30% fly ash, 5% zeolite, and 10% attapulgite, which are taken according to the mass percentage each component;

[0048] b. Preparation of cured body: put the components of the cured material described in step a, water glass, and cellulose ether in a (specific) container, and then add the high-salt, high-alkali, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com