Single-wheel horizontal biomass extrusion molding machine

A biomass and molding machine technology, applied in material molding presses, presses, manufacturing tools, etc., can solve the problems of difficult to control the extrusion effect, uneven feeding of the mixer, and complicated extrusion conditions, and achieve the molding effect. Good, not easy to get bored, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

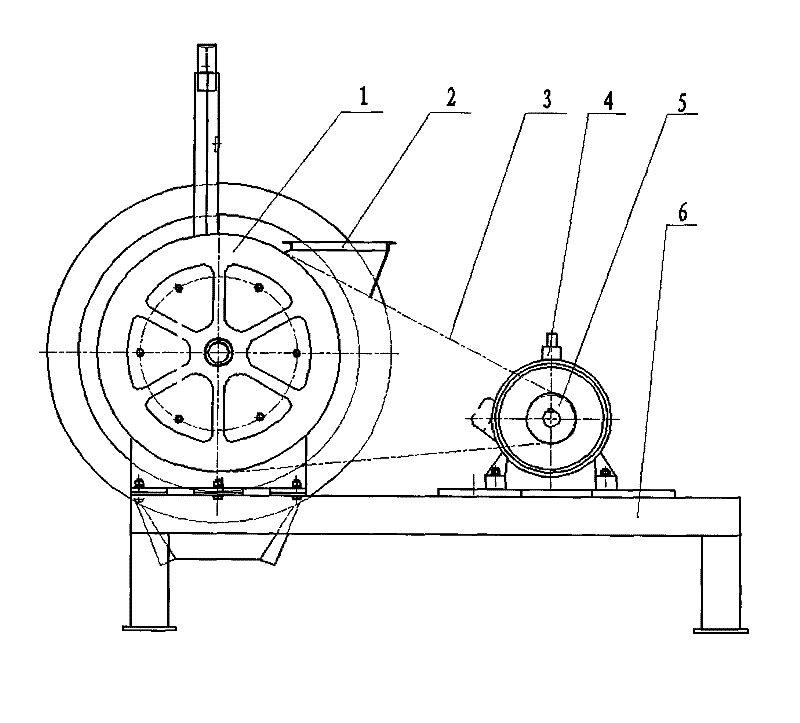

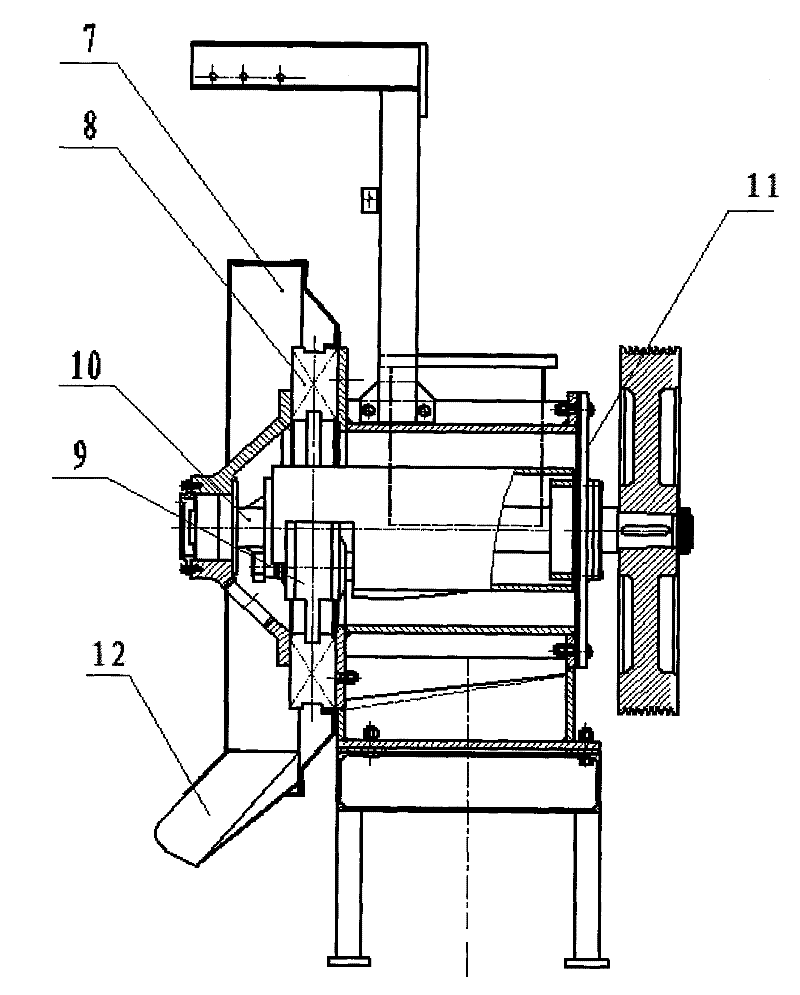

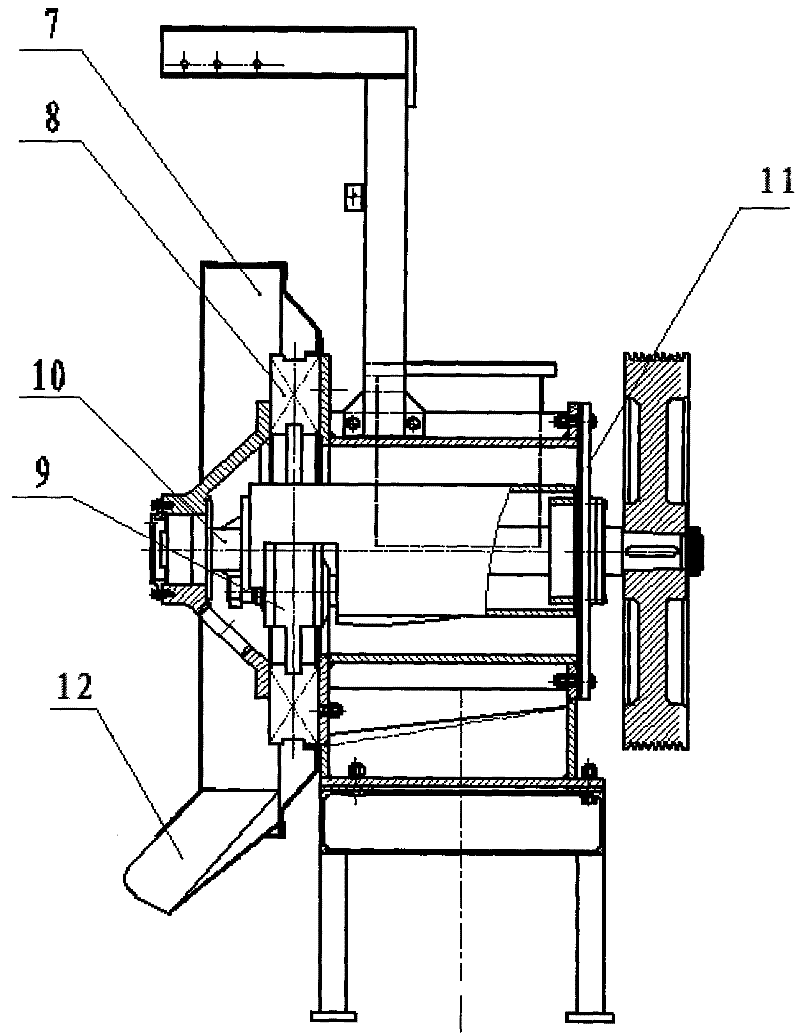

[0015] Such as figure 1 , 2 As shown, the single-wheel horizontal biomass extrusion molding machine described in the embodiment of the present invention includes a large pulley 1, a feeding hopper 2, a transmission belt 3, a motor 4, a frame 6, a material retaining shield 7, a mold Disk 8, extrusion wheel 9, main shaft 10, sealing body 11, the right side of the frame 6 fixes the motor 4 through the motor seat, and the output end of the motor 4 fixes the small pulley 5; the left side of the frame 6 is threaded to fix the seal body 11, the inside of the sealing body 11 runs through the main shaft 10 horizontally, and the main shaft 10 is fixed on both sides of the sealing body 11 through bearings near the two ends. The double support fixing method of the main shaft 10 avoids cantilever support, and the forming effect is good. One end fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com