Laser imaging device and method with unequal distances

A laser imaging and spacing technology, which is applied in photoelectric typesetting devices, phototypesetting devices, printing, etc., can solve the problem of inflexible typesetting design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

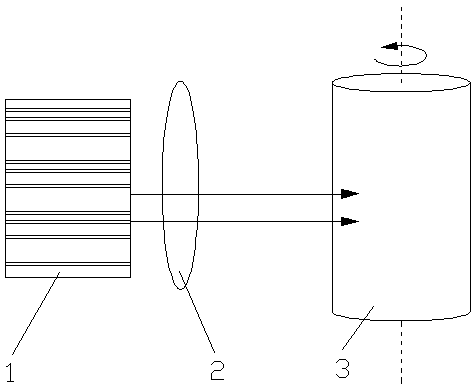

[0022] Refer to attached figure 1 The shown laser imaging device with unequal spacing includes a laser chip 1 that emits a plurality of parallel and spaced laser arrays, an optical element 2 that focuses the light beams, a printed substrate on which the laser arrays are imaged, and drives The drum 3 on which the printed substrate rotates.

[0023] The optical element 2 in this embodiment is a micro-optical lens array, and the printed substrate is a heat-sensitive stencil that can be sensitive to laser light or generate heat by absorbing laser energy.

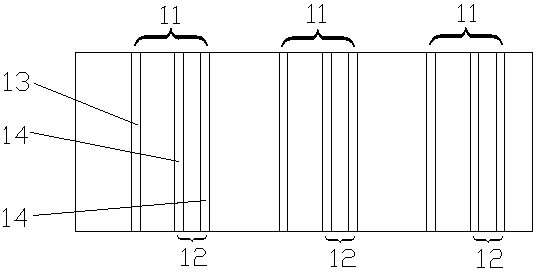

[0024] Refer to attached figure 2 The laser array emitted by the shown laser chip 1 includes a plurality of laser groups 11 spaced apart from each other, and the distance between every two adjacent laser groups 11 is a first distance, and each laser group 11 includes a first Laser 13 and laser group 12, the spacing between the first laser 13 and the laser group 12 is the second spacing, the second spacing is not equal ...

Embodiment 2

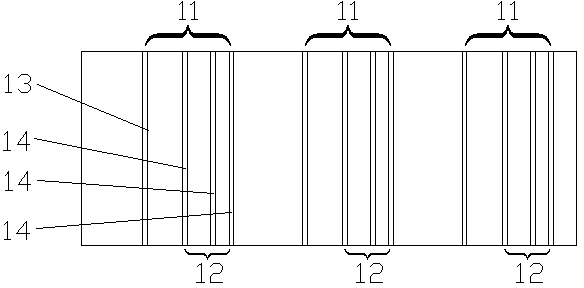

[0031] The components of the laser imaging device with unequal pitches in this embodiment are basically the same as those in the first embodiment above, except that the laser arrays emitted by the laser chip 1 have different pitches.

[0032] Refer to attached image 3 , the laser array includes a plurality of laser groups 11 spaced apart from each other, the spacing between every two adjacent laser groups 11 is a first pitch, each laser group 11 includes a first laser 13 and a laser group 12, the first laser 13 The spacing between the laser group 12 is the second spacing, and the second spacing is not equal to the first spacing. Each laser group 12 includes at least two second laser beams 14, and the adjacent second lasers in each laser group 12 The distance between 14 is not equal to the second distance and the first distance respectively. In this embodiment, there are more than 2 second laser beams 14 in the laser group 12, and there are 3 beams, and the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com