Novel oil gas recovery control system of gas station

A control system and gas station technology, applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as volatile and unsuitable, and achieve the effect of precise adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

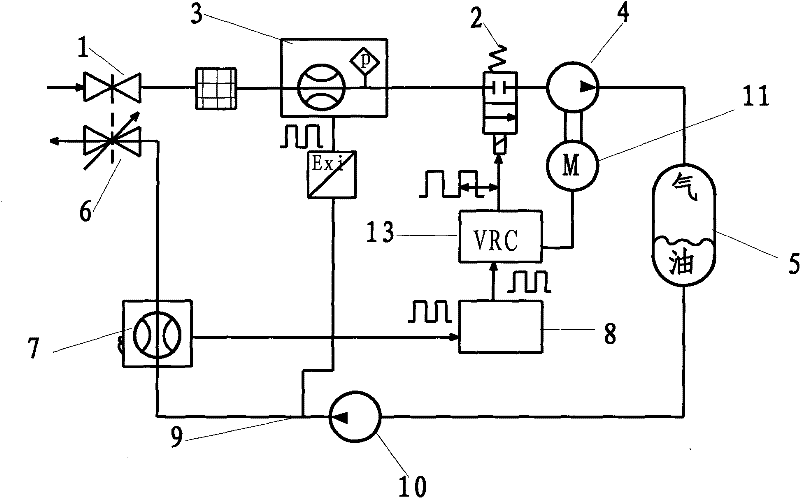

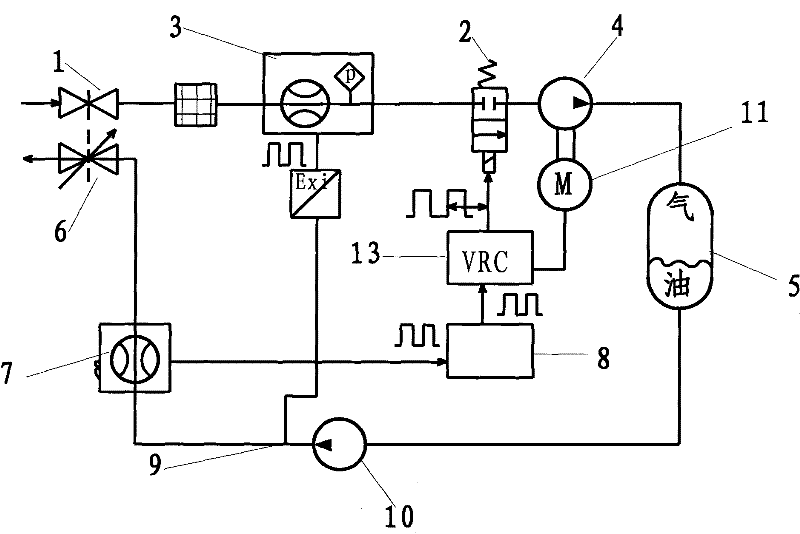

[0025] A novel gas recovery control system for a gas station of the present invention includes a flow metering pulse sensor 8, a controller 13, a recovery motor 11, a vacuum vane pump 4 for oil recovery, a gas return valve 1, a filter valve 2, and a gas flow regulating valve 3 ; Air return valve 1, gas flow regulating valve 3, filter valve 2, vacuum oil and gas recovery vane pump 4 and oil tank 5 are connected sequentially; It is connected with controller 13, recovery motor 11 and vacuum oil vapor recovery vane pump 4 successively, and the recovery motor adopts frequency conversion motor; controller 13 is connected with filter valve 2 signals; gas station oil recovery control system of the present invention also includes being arranged on the fuel pipe The temperature sensor 9 between the refueling pump and the flow meter on the road, and the gas flow regulating valve control device 12 connected with the temperature sensor 9 signal, the gas flow regulating valve control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com