Method for manufacturing microcrystalline glass by cyanite tailing

A technology for kyanite tailings and glass-ceramics, which is applied in the field of building material synthesis to achieve the effects of low cost and energy consumption, high utilization rate of tailings, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

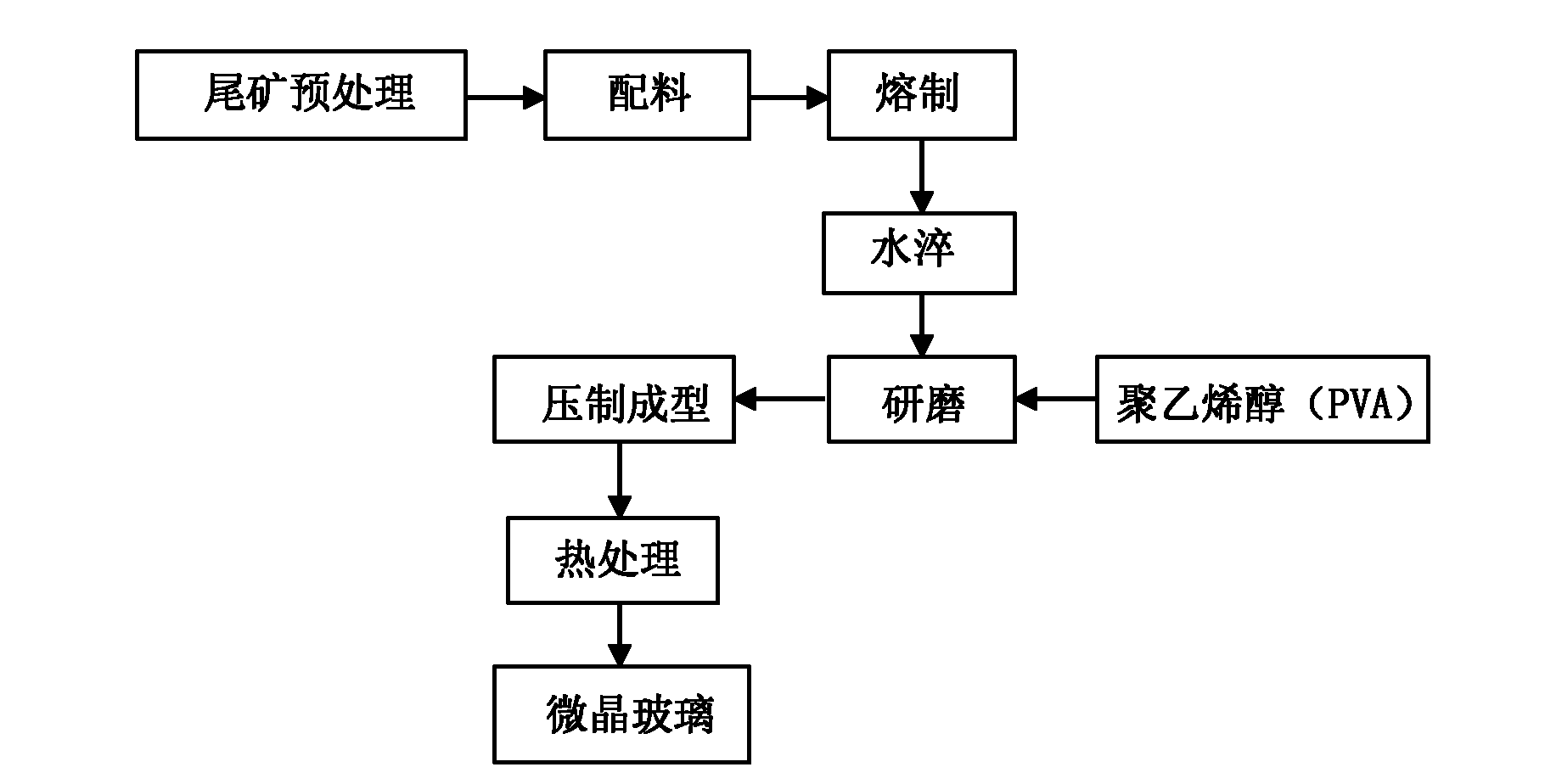

Method used

Image

Examples

Embodiment 1

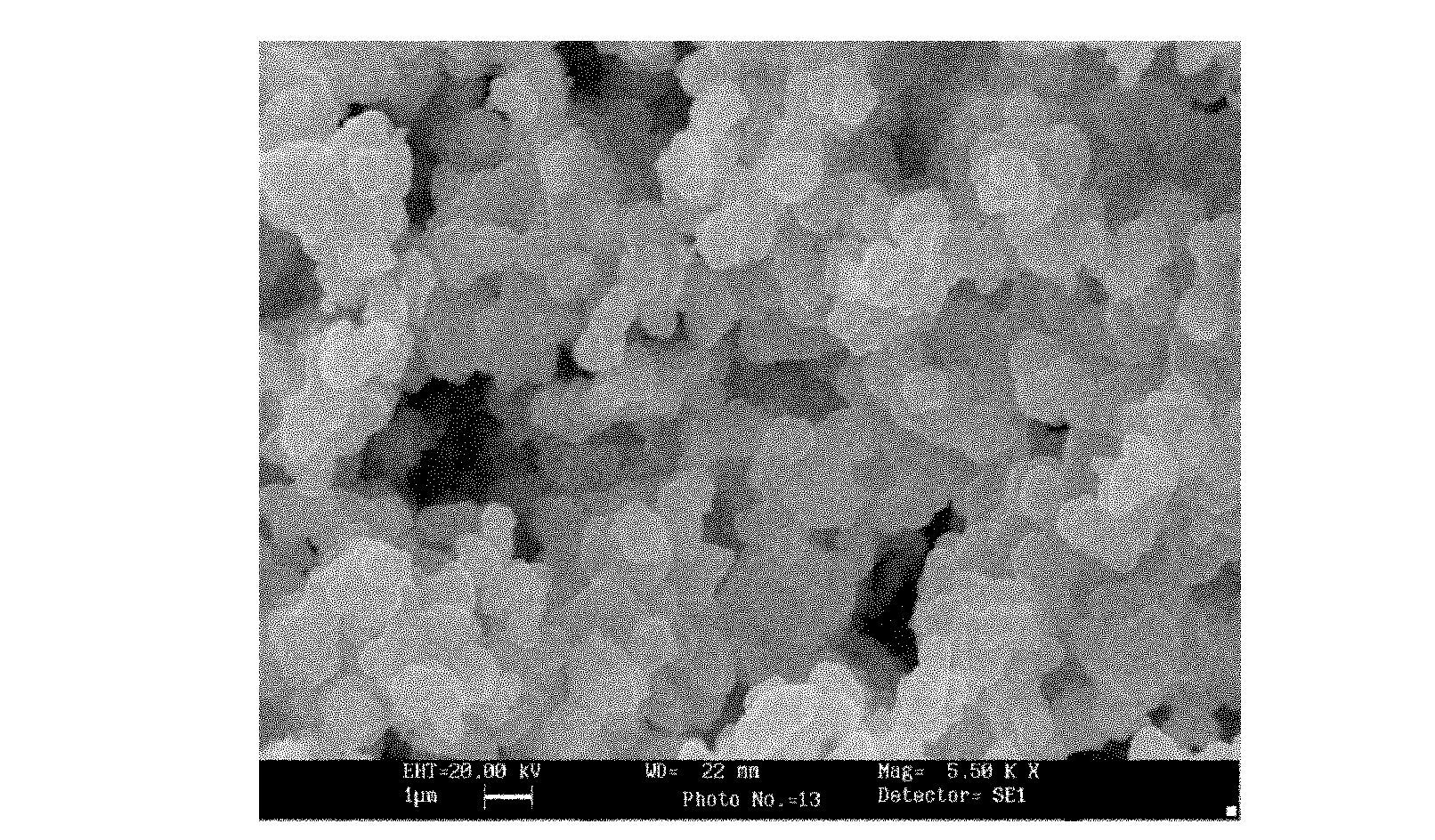

[0028] Within the composition range of each chemical substance that can form glass-ceramics designed in the present invention, select according to the mass fraction of batching: tailings 64.6% after pretreatment, Al 2 o 3 10.0﹪, CaO 16.2﹪, Na 2 CO 3 3.0% TiO2 2 1.2%, BaO 2.4%, ZnO 2.6%. After mixing evenly, melt at a high temperature of 1200°C, quench the molten slurry in water, collect the quenched small particle frit, dry it, crush it to 200 mesh with a ball mill, add 2% polyvinyl alcohol, and carry out Granulate. Then use the corresponding mold to press it into the desired shape under the pressure of 20MPa, and conduct heat treatment at a heating rate of 4°C / min. Select the heat treatment system of nucleation at 800°C for 2 hours and crystallization at 920°C for 2 hours for heat treatment, and natural annealing to obtain glass ceramics. figure 2 It is the SEM picture corresponding to magnification of 5500 times.

Embodiment 2

[0030] Selected according to the mass fraction of the ingredients: 70.3% of tailings after pretreatment, Al 2 o 3 6.3%,CaO 15.2%,Na 2 CO 3 2.0% TiO2 2 1.0%,P 2 o 5 0.3%, BaO 2.3%, ZnO 2.6%. After mixing evenly, melt at a high temperature of 1300°C, quench the molten slurry in water, collect the quenched small particle frit, dry it, crush it to 200 mesh with a ball mill, add 1% polyvinyl alcohol, and carry out Granulate. Then use the corresponding mold to press it into the desired shape under the pressure of 40MPa, and conduct heat treatment at a heating rate of 3°C / min. Select the heat treatment system of nucleation at 810°C for 2 hours and crystallization at 940°C for 2 hours for heat treatment, and natural annealing to obtain glass-ceramics.

Embodiment 3

[0032] Select according to the mass fraction of ingredients: tailings after pretreatment 55.5%, Al 2 o 3 8.7﹪, CaO 22.0﹪, Na 2 CO 3 5.2%,Cr 2 o 3 1.6%, BaO 3.3%, ZnO 3.7%. After mixing evenly, melt at a high temperature of 1400°C, quench the molten slurry in water, collect the quenched small particle frit, dry it, crush it to 200 mesh with a ball mill, add 2.2% polyvinyl alcohol, and carry out Granulate. Then use the corresponding mold to press it into the desired shape under the pressure of 80MPa, and conduct heat treatment at a heating rate of 3°C / min. Select the heat treatment system of nucleation at 800°C for 3 hours, heating to 915°C for crystallization for 3 hours for heat treatment, and natural annealing to obtain glass-ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com