Premixed natural gas combustion nozzle for magnesium smelting and reducing and heat storage

A regenerative combustion and natural gas technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of slow contact between natural gas and preheated air, uneven mixing, large temperature deviation on the furnace surface, and ineffective combustion. Achieve the effects of increasing the output of a single tank, uniform temperature in the furnace, and reducing natural gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

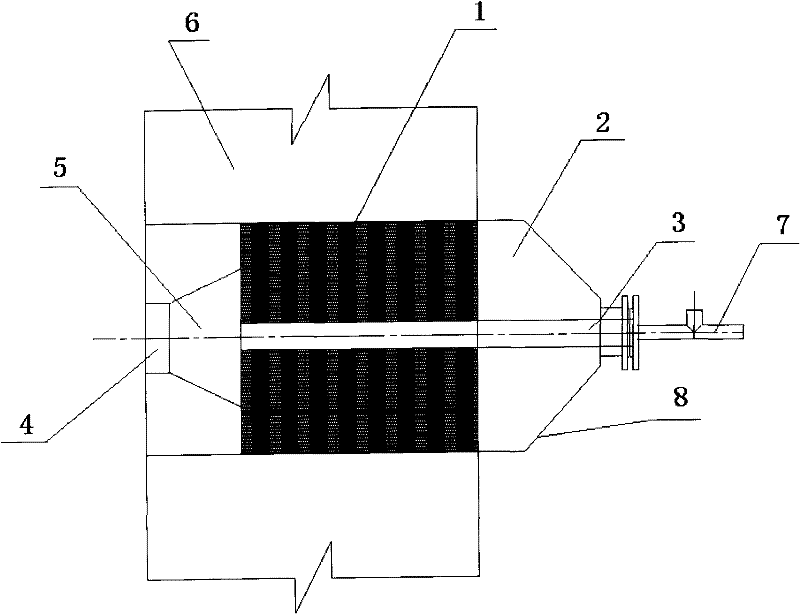

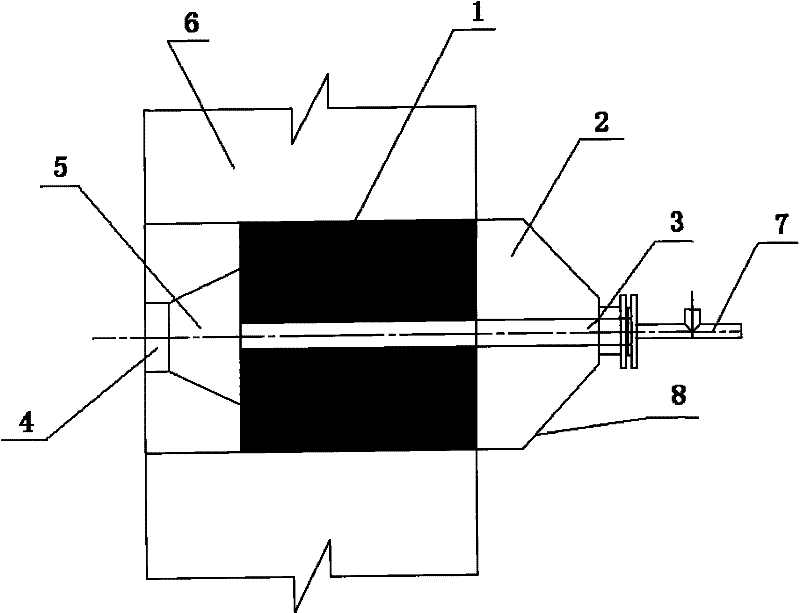

[0010] The premixed natural gas magnesium smelting reduction regenerative combustion nozzle of the present invention consists of a regenerator 1, an air box 2, a central nozzle 3, a mixed gas nozzle 4, a premixing chamber 5, a smelting furnace wall 6, a natural gas inlet pipe 7 and a nozzle shell body 8; the center of the nozzle housing 8 is installed with the center nozzle 3, one end of the center nozzle 3 is connected to the natural gas inlet pipe 7, and the bellows 2 and the regenerator 1 are sequentially set in the nozzle housing 8 coaxially, and the center nozzle 3 The other end communicates with the premixing chamber 5, and the front end of the premixing chamber 5 is connected to the mixed gas nozzle 4; The gas nozzle 4 is composed of corundum or heat-resistant steel; the regenerator 1 is composed of refractory bricks and honeycomb regenerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com