Experiment device for simulating atomic oxygen oxidation ground of super-high temperature heat-protection material

A technology of heat-resistant materials and experimental devices, applied in the direction of material excitation analysis, mechanical excitation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

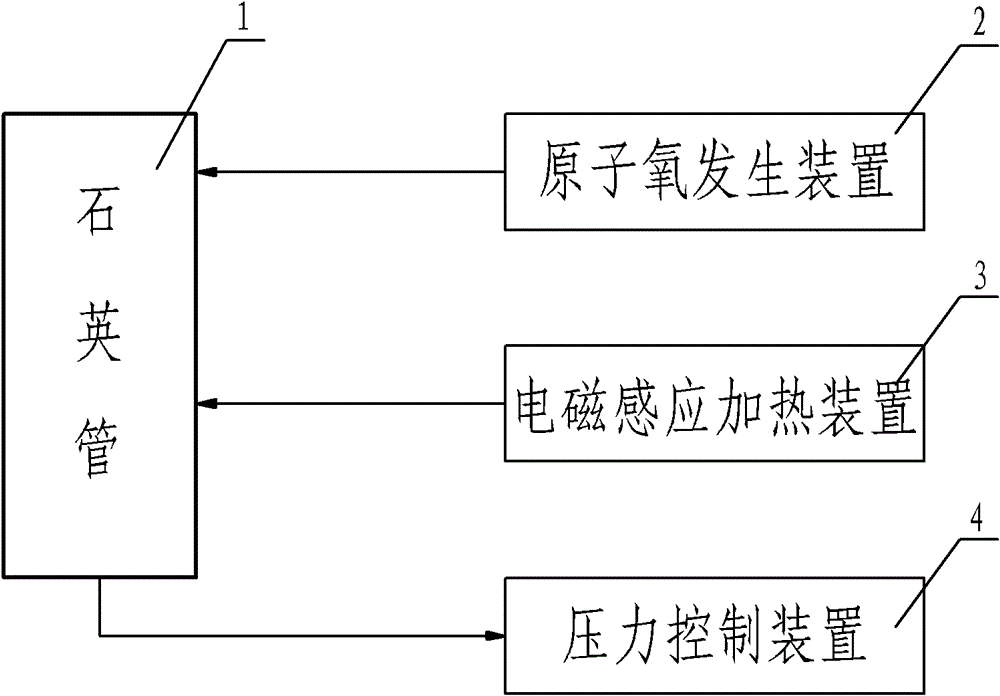

[0007] to combine figure 1 , Figure 5 Describe this embodiment, it comprises quartz tube 1, atomic oxygen generator 2, electromagnetic induction heating device 3 and pressure control device 4, and the atomic oxygen output end of atomic oxygen generator 2 is connected to the atomic oxygen input of quartz tube 1 The air output end of the quartz tube 1 is connected to the air input end of the pressure control device 4, and the output end of the electromagnetic induction heating device 3 is respectively connected to an input end of the induction heating coil 9 sleeved on the outer wall of the middle part of the quartz tube 1.

[0008] This experimental device is an experimental device that can reproduce the environment of high temperature, low pressure, and atomic oxygen during the flight of a hypersonic vehicle, and it is an experimental device for studying the oxidation behavior of conductive heat-resistant materials. ℃, and the pressure ranges from 10 to 5000Pa, the device ca...

specific Embodiment approach 2

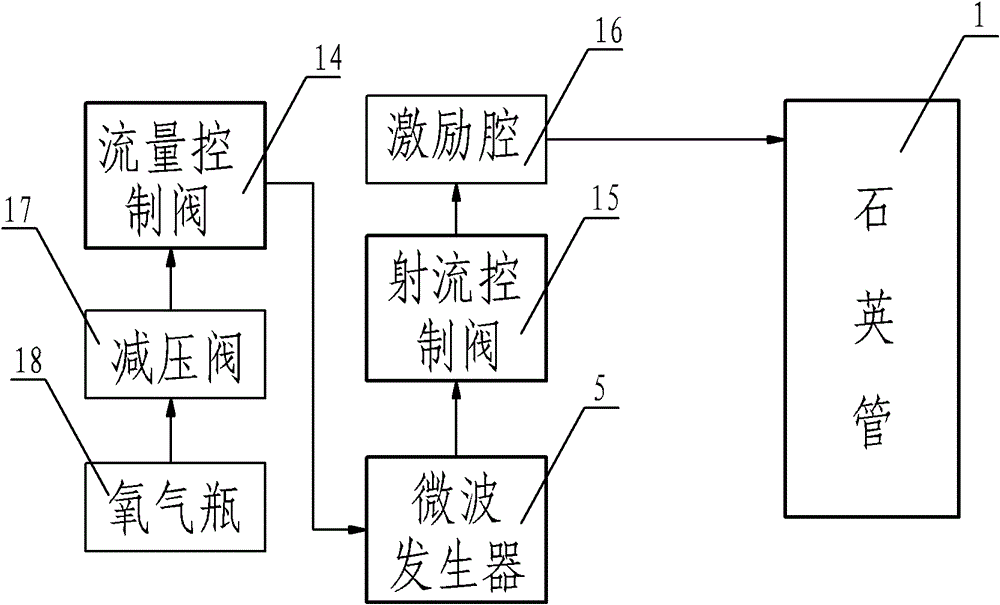

[0009] to combine figure 2 , Figure 5 Describe this embodiment, the atomic oxygen generator 2 of this embodiment comprises an oxygen cylinder 18, a pressure reducing valve 17, a flow control valve 14, a microwave generator 5, a jet flow control valve 15 and an excitation chamber 16, and the output end of the oxygen cylinder 18 is connected At the input end of the pressure reducing valve 17, the output end of the pressure reducing valve 17 is connected to the input end of the flow control valve 14, and the oxygen output end of the flow control valve 14 is connected to the oxygen input end of the microwave generator 5, and the oxygen output end of the microwave generator 5 The output end is connected to the input end of the jet control valve 15 , the output end of the jet control valve 15 is connected to the input end of the excitation chamber 16 , and the output end of the excitation chamber 16 is connected to the atomic oxygen input end of the quartz tube 1 . Other componen...

specific Embodiment approach 3

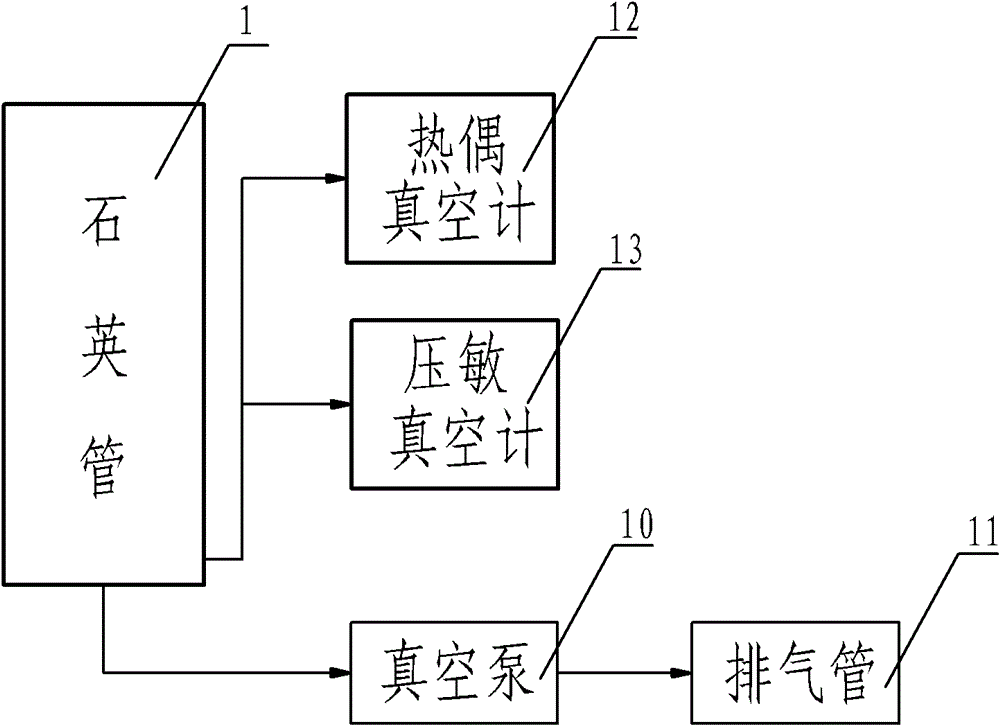

[0010] to combine image 3 , Figure 5 Describe this embodiment, the pressure control device 4 of this embodiment includes a vacuum pump 10, an exhaust pipe 11, a thermocouple vacuum gauge 12 and a pressure-sensitive vacuum gauge 13, the air output end of the quartz tube 1 is connected to the air input end of the vacuum pump 10, The air output end of the vacuum pump 10 is connected to the air input end of the exhaust pipe 11 , and the internal pressure signal output end of the quartz tube 1 is respectively connected to the input ends of the thermocouple vacuum gauge 12 and the pressure sensitive vacuum gauge 13 . Other components and connections are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com