Glass-micropipe-based single nanopore sensor and manufacturing method thereof

A technology of nanopore sensor and glass microtube, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for sensing, which can solve the problems of limited resolution and inability to judge the movement state of the measured medium, and achieve high sensitivity, The effect of simple method and high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

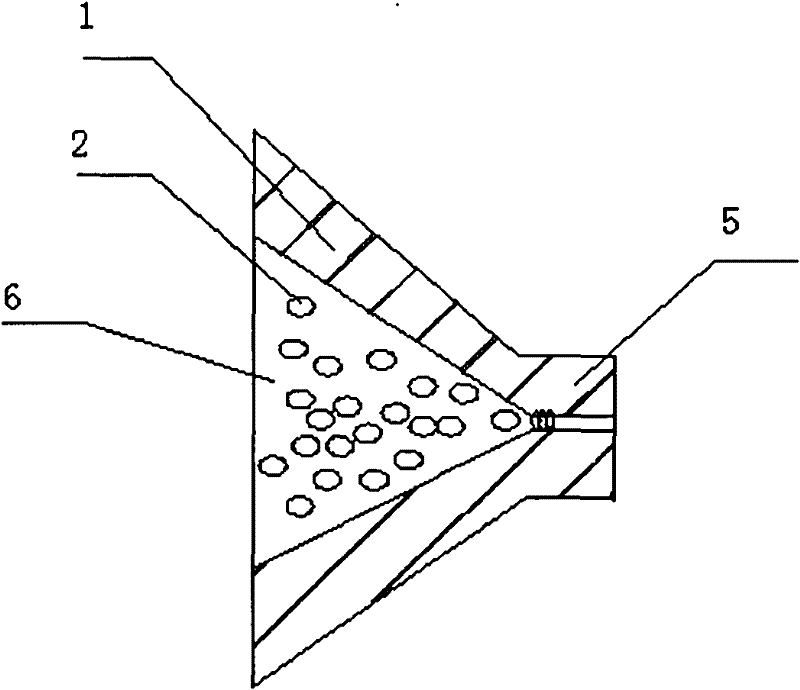

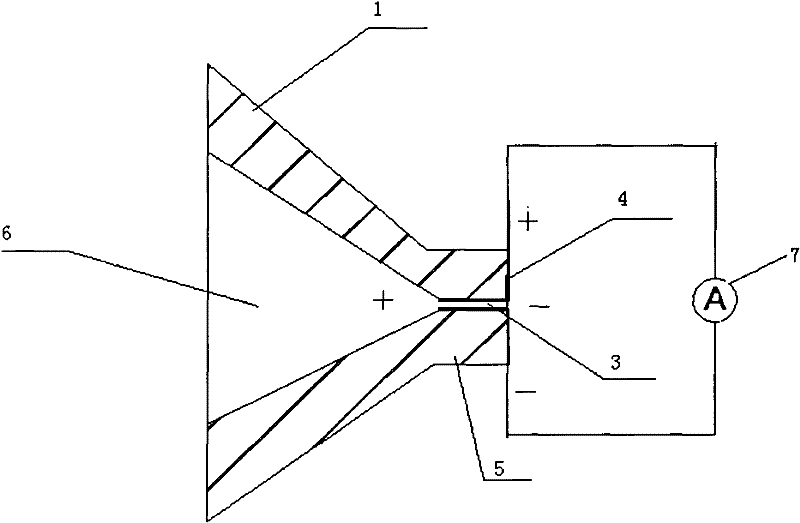

[0019] The single nanopore sensor of the present invention includes a glass microtube 1, which includes a protrusion 5 at the right end, a single nanopore 3 is provided in the protrusion 5, and a fluid chamber is respectively provided at both ends of the single nanopore 3, The two fluid chambers are connected by a single nanopore 3, a first voltage source is used to provide a voltage between the two fluid chambers, and two Pt electrodes 4 are provided on the protrusion 5 on the upper and lower sides of the single nanopore 3, which are detected by an ammeter 7 For the current between the two Pt electrodes 4, the two ends of the ammeter 7 are respectively connected to the two Pt electrodes 4, a second voltage source is used to provide the voltage between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com