Mobile distillation system and process for producing a distilled product while transporting the same

A distillation system and power technology, applied in the field of distillation, to achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

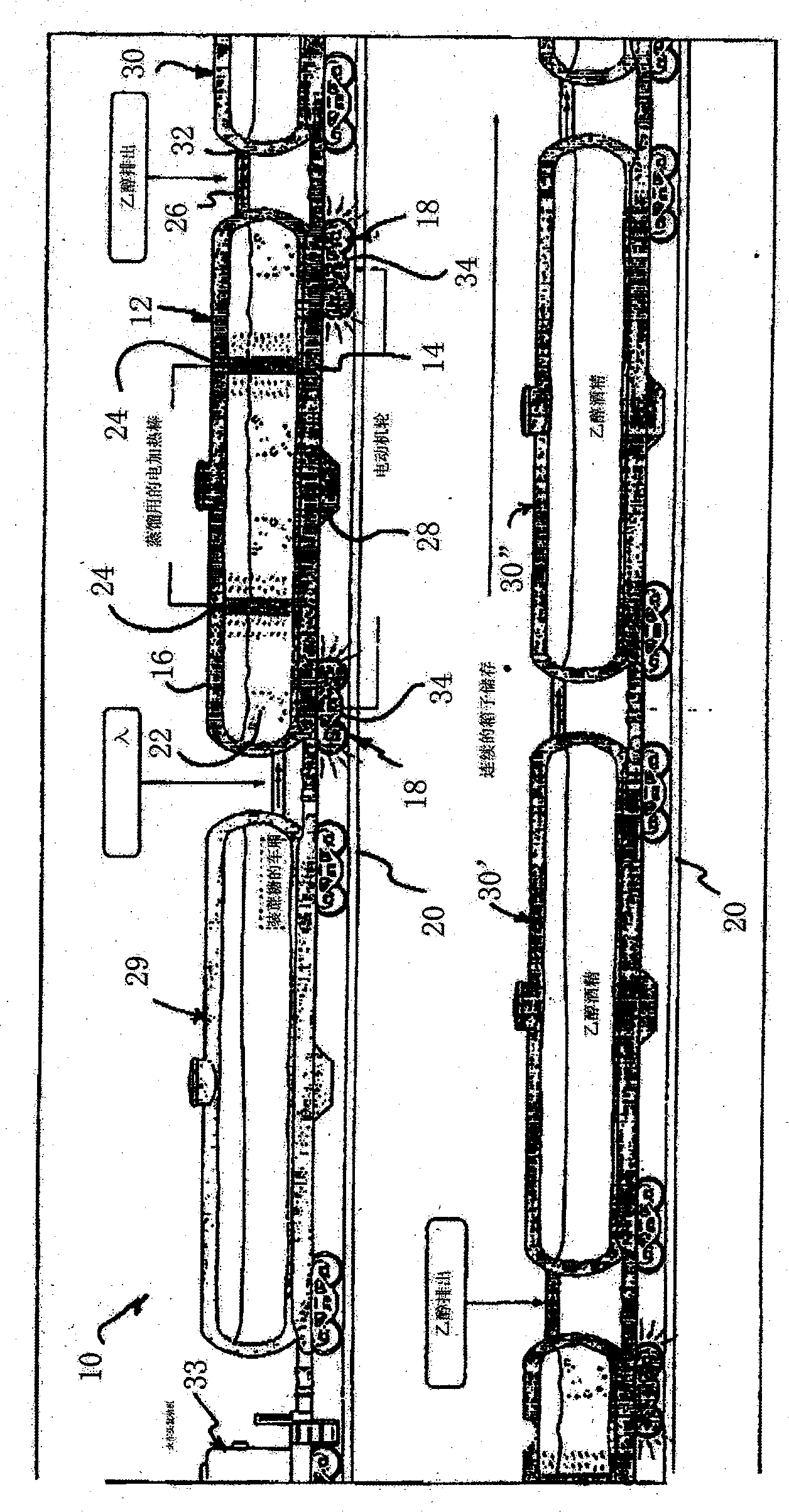

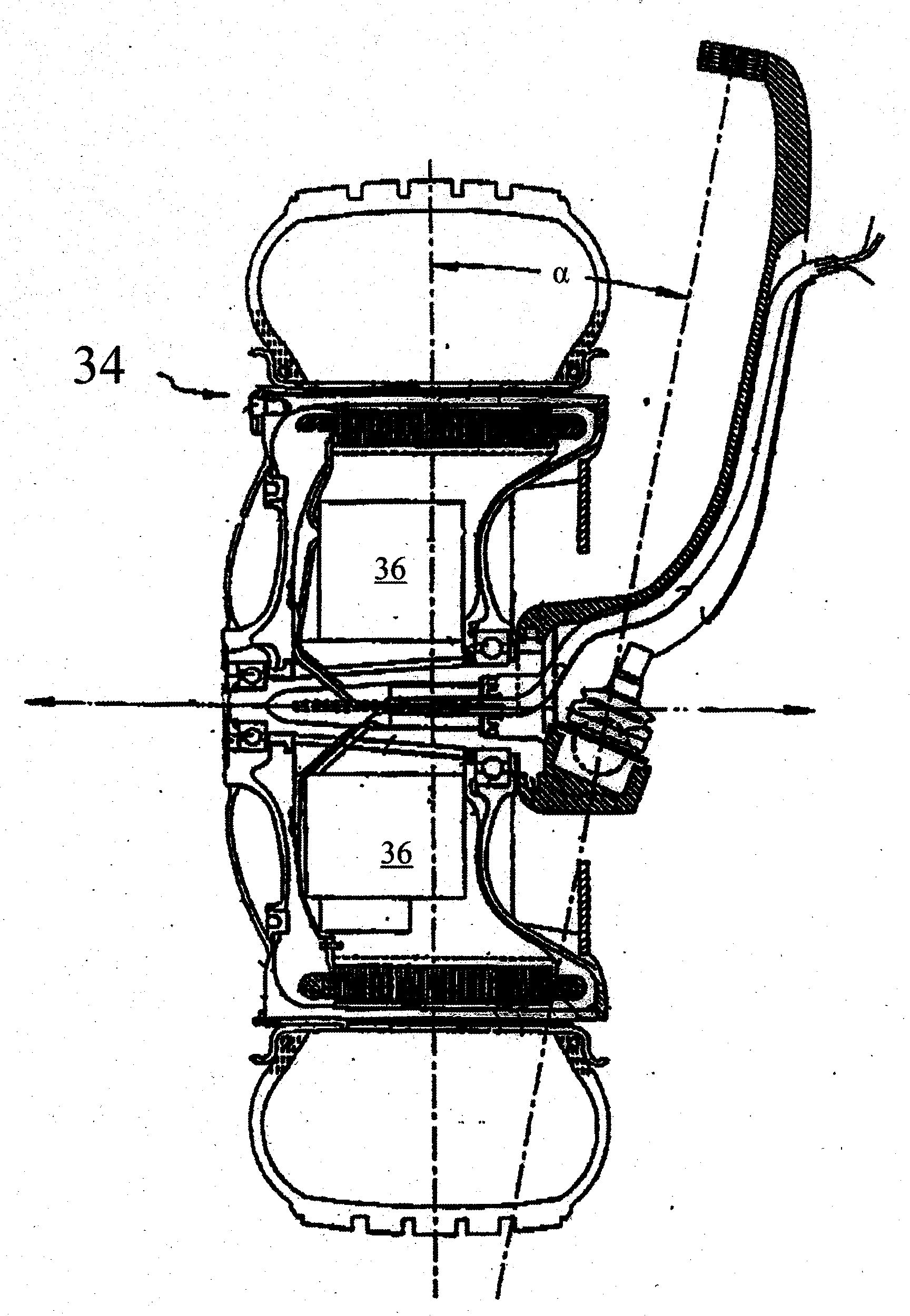

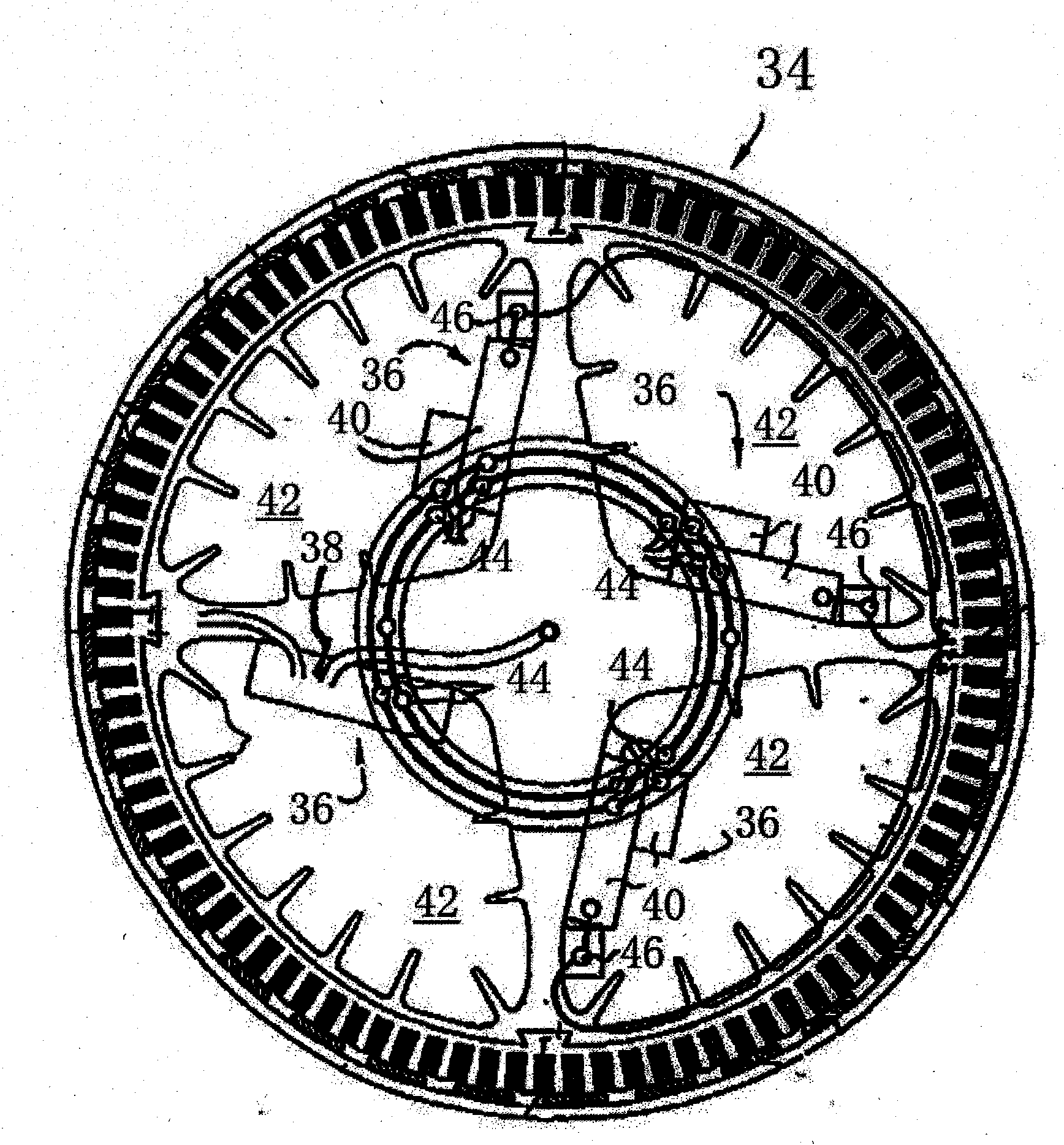

[0030] Two preferred embodiments of the mobile distillation system of the present invention are described below.

[0031] Such as figure 1 In the first embodiment shown, the mobile distillation system is provided with a train 10 connected thereto. The train 10 has a first car 12 (hereinafter referred to as a retort car) which includes a chassis 14 and a box 16 secured thereto. The chassis is provided with a wheel assembly 18 in contact with crawler belts 20 .

[0032] The tank 16 of the distillation car 12 is filled with a liquid 22, which is preferably a sugar or starch fermentation product. Preferably, the fermentation process is completed before the mobile distillation process, said fermentation liquid is provided by the distillation compartment 12 . Said liquid 22 thus contains water and fermentation products, including ethanol. The distillation compartment 12 is also provided with a plurality of heaters 24 , all of which are provided with electric heating rods immerse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com