Toner

A technology of toner and colorant, applied in the field of toner, can solve problems such as degradation and poor performance, and achieve the effect of excellent stain resistance and good durability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0262] (a) Preparation of solvent

[0263] As the sample solvent, use a mixture of ether and ethanol (1+1 or 2+1), or a mixture of benzene and ethanol (1+1 or 2+1), and use phenolphthalein as an indicator when any such solvent is used. Immediately before the solution of the agent, neutralize it with a solution of 0.1 mol / l potassium hydroxide in ethanol.

[0264] (b) Preparation of phenolphthalein solution

[0265] 1 g of phenolphthalein was dissolved in 100 ml of ethanol (95 v / v %).

[0266] (c) Preparation of a solution of 0.1mol / l potassium hydroxide in ethanol

[0267] Dissolve 7.0 g of potassium hydroxide in as little water as possible. Ethanol (95 v / v%) was added to the solution so that the mixture had a volume of 1 liter. The mixture was left for 2-3 days, then filtered. Calibration was carried out in accordance with JIS-K8006 (basic items concerning titration during reagent content testing).

[0268] (2) Operation

[0269] Accurately weigh 1-20 g of the sample, ...

Embodiment 1

[0433] (Step of forming monomer composition)

[0434] Styrene (St): 70 parts by mass

[0435] n-butyl acrylate (Ba): 30 parts by mass

[0436] Pigment blue 15:3: 8 parts by mass

[0437] Aluminum salicylate compound (BONTRON E-88: manufactured by Orient Chemical Industries Co., Ltd.): 0.5 parts by mass

[0438] The above-mentioned styrene acrylic resin 1: 18 parts by mass

[0439] The above-mentioned sulfonic acid resin 1: 3.5 parts by mass

[0440] Divinylbenzene (DVB): 0.9 parts by mass

[0441] Wax (HNP-10: manufactured by NIPPON SEIRO CO., LTD.): 10 parts by mass

[0442] First, a mixture of the above materials is prepared. Next, 15 mm ceramic beads were added to the mixture, followed by dispersion using an attritor for 3 hours. Then, remove the beads. As a result, a monomer composition was obtained.

[0443] (Step of forming an aqueous dispersion of a dispersant)

[0444] First, 700 parts by mass of ion-exchanged water and 450 parts by mass of 0.1mol / l Na 3 PO ...

Embodiment 2-6, and comparative example 2、4、6-8、10 and 11

[0458] Except that the type and amount of raw materials in Example 1 and the reaction temperature were changed to the conditions shown in Table 5, toners 2-6, 10, 12, 14-16, 18 and 19 were obtained in the same manner as in Example 1. . Tables 6-1 and 6-2 show the physical properties of Toners 2-6, 10, 12, 14-16, 18 and 19. Toners 2-6, 10, 12, 14-16, 18 and 19 were each subjected to performance evaluation in the same manner as in Example 1. Table 7 shows the performance evaluation results of Toners 2-6, 10, 12, 14-16, 18 and 19.

PUM

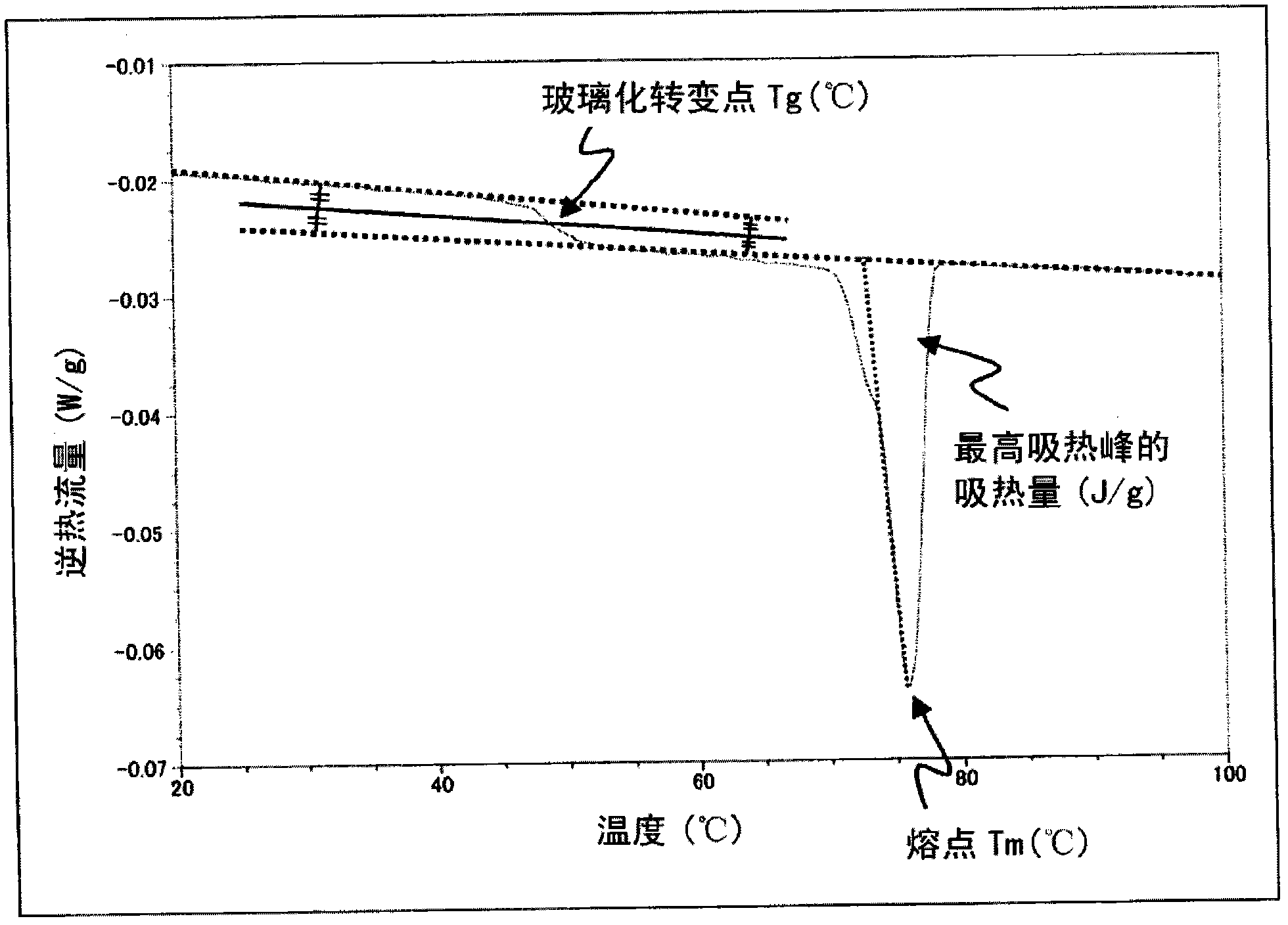

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com