Sustained release non-protein nitrogen feed and preparation

A technology of non-protein nitrogen and feed, which is applied in the field of slow-release non-protein nitrogen feed and the preparation of the feed, can solve the problems of uneven coating of slow-release non-protein nitrogen feed, prolong the slow-release time, etc., to improve palatability, The effect of evenly wrapping and reducing the chance of poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

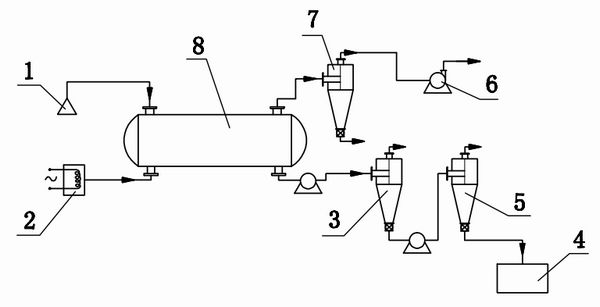

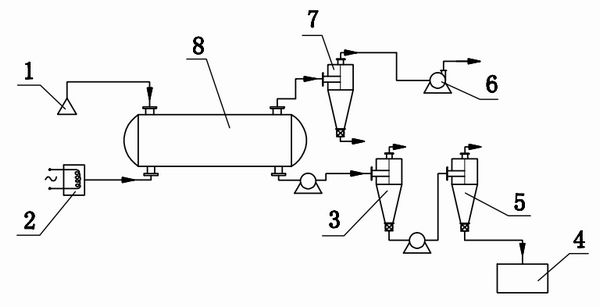

[0017] The drying equipment that this embodiment adopts sees figure 1 . It includes a mixer 1, a heating device 2, a rotary heat exchanger 8, a first cyclone separator 3, a second cyclone separator 5, a third cyclone separator 7, an induced draft fan 6 and a collector 4; The inlet of the inner tube of the rotary heat exchanger 8 communicates with the outlet of the heating device 2 through a pipeline, and the outlet of the inner tube of the rotary heat exchanger 8 communicates with the inlet of the third cyclone separator 7 through a pipeline; The bottom outlet of the third cyclone separator 7 is connected to the dust collection device, and the upper outlet of the third cyclone separator 7 is communicated with the inlet of the induced draft fan 6;

[0018] The inlet of the outer tube of the rotary heat exchanger 8 is connected to the outlet of the mixer 1 through an auger conveyor, and the outlet of the outer tube of the rotary heat exchanger 8 is separated from the first cycl...

Embodiment 2

[0029] The equipment that adopts is with embodiment 1.

[0030] The difference from the examples is: 1) Weigh 20 parts by weight of corn flour and 20 parts by weight of urea, mix and pulverize, and then pass through a 100-mesh sieve to obtain a mixture;

[0031] 2) Add the mixture described in step 1) into mixer 1, add 10 parts by weight of molasses, mix well, and then transport the three mixtures in mixer 1 to the rotary heat exchanger through the conveying auger gelatinization at 140~150°C in the outer tube;

[0032] 3) The gelatinized product is cooled by the first cyclone separator and the second cyclone separator, and crushed after cooling to obtain the slow-release non-protein nitrogen feed.

Embodiment 3

[0034] Different from Example 1, the raw materials of following parts by weight are adopted:

[0035] 70 parts of urea, 30 parts of molasses, 60 parts of soybean meal powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com