A method for preparing hydrogenated C9 petroleum resin by directional hydrogenation

A technology for carbon 9 petroleum resin and petroleum resin, which is applied in the field of directional hydrogenation to prepare hydrogenated carbon 9 petroleum resin, can solve the problems of staying in the experimental stage and high catalyst cost, and achieve the advantages of improving product quality, good thermal stability and improving life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

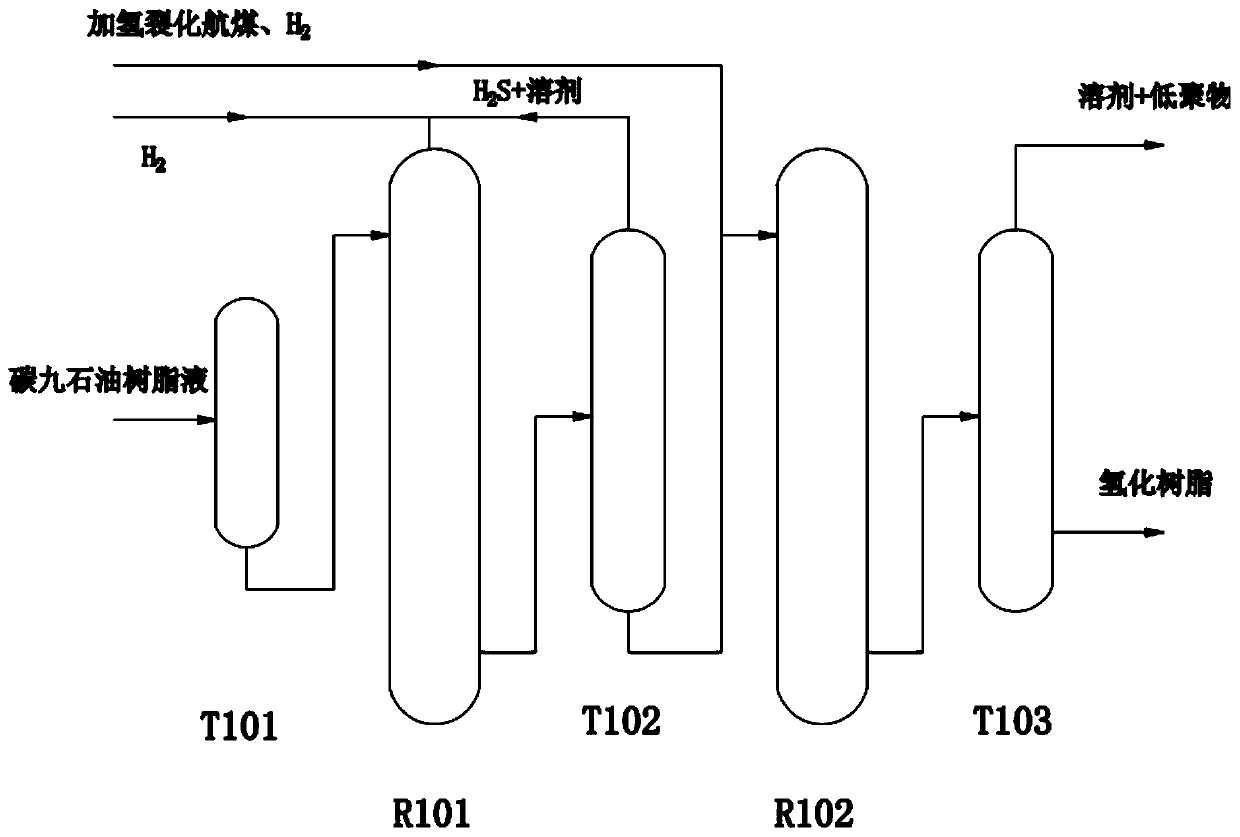

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix the softening point of 120°C, Gardner color number 11# C9 petroleum resin and the mixed solvent (trimethylbenzene and naphthenic oil with a mass ratio of 1:1) evenly at a mass ratio of 1:1, and then pass the temperature to 280°C Al 2 o 3 Packed bed T101 removes colloid and other impurities to make the colloid content <10mg / 100mL to obtain pretreated resin liquid.

[0036] (2) The pretreated resin liquid is transported into the loaded Ni / Mo / W-Al 2 o 3 Catalyst (loaded metal content is 40wt%, metal element molar ratio Ni:Mo:W=1:0.9:0.4, specific surface area 140m 2 / g, pore volume 0.5cm 3 / g, a particle size of 4mm) in a hydrogenation reactor R101 for hydrogenation reaction; wherein, the hydrogenation reaction temperature is 220°C, the reaction pressure is 13MPa, the hydrogen-oil ratio is 500:1, and the liquid hourly space velocity (LHSV) is 2h -1 , to obtain a hydrogenated resin solution.

[0037] (3) The hydrogenated resin liquid of the above-mentioned sta...

Embodiment 2

[0041] (1) Mix the softening point of 113°C, Gardner color number 9# C9 petroleum resin and the mixed solvent (trimethylbenzene and naphthenic oil at a mass ratio of 1:2) evenly at a mass ratio of 1:3, and then pass the temperature to 300°C Al 2 o 3 Packed bed T101 removes colloid and other impurities to make the colloid content <10mg / 100mL to obtain pretreated resin liquid.

[0042] (2) The pretreated resin liquid is transported into the loaded Ni / Mo / W-Al 2 o 3 Catalyst (loaded metal content is 30wt%, metal element molar ratio Ni:Mo:W=1:1:0.5, specific surface area 140m 2 / g, pore volume 0.5cm 3 / g, particle size 4mm) of a hydrogenation reactor R101 for hydrogenation reaction; wherein, the hydrogenation reaction temperature is 270°C, the reaction pressure is 16MPa, the hydrogen-oil ratio is 500:1, and the liquid hourly space velocity (LHSV) is 2h -1 , to obtain a hydrogenated resin solution.

[0043] (3) The hydrogenated resin liquid of the above-mentioned stage is tran...

Embodiment 3

[0047] (1) Mix the softening point of 117°C, Gardner color number 10# C9 petroleum resin and the mixed solvent (trimethylbenzene and naphthenic oil with a mass ratio of 1:3) evenly at a mass ratio of 1:3, and then pass the temperature to 300°C Al 2 o 3 Packed bed T101 removes colloid and other impurities to make the colloid content <10mg / 100mL to obtain pretreated resin liquid.

[0048] (2) The pretreated resin liquid is transported into the loaded Ni / Mo / W-Al 2 o 3 Catalyst (loaded metal content is 30wt%, metal element molar ratio Ni:Mo:W=1:1:0.3, specific surface area 150m 2 / g, pore volume 0.5cm 3 / g, particle size 4mm) of a hydrogenation reactor R101 for hydrogenation reaction; wherein, the hydrogenation reaction temperature is 260°C, the reaction pressure is 15MPa, the hydrogen-oil ratio is 500:1, and the liquid hourly space velocity (LHSV) is 3h -1 , to obtain a hydrogenated resin solution.

[0049] (3) The hydrogenated resin liquid of the above-mentioned stage is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com